Top entry floating ball valve capable of being maintained on line

A floating ball valve and top loading technology, which is applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of unrealized valves, etc., and achieve the effect of simple structure, easy structure, and good sealing performance of the valve seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

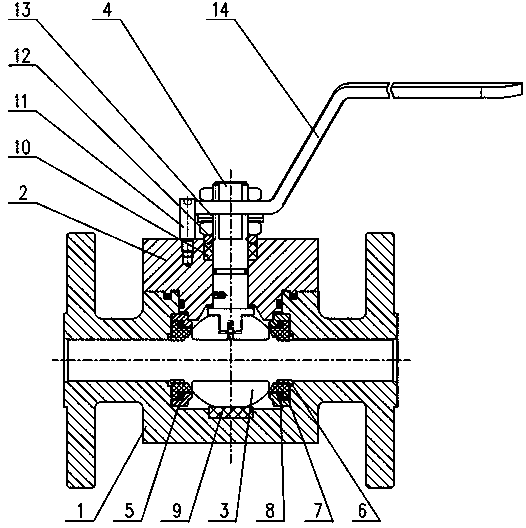

[0014] Such as figure 1 As shown, a top-entry floating ball valve that can be maintained online, a top-entry floating ball valve that can be maintained online, includes a valve body 1, a valve cover 2 matched with the valve body, a ball 3, a valve stem 4, and an outer clamp Device 5, inner holder 6, seal ring 7, O-ring 8, thrust pad 9, valve stem packing 10, pressure sleeve 11, set screw 12, butterfly spring 13, handle 14; ball 3 is set on valve body 1 Inside, the bonnet 2 is arranged on the upper part of the valve body 1 to form a cavity to seal the sphere 3; the valve stem 4 passes through the top of the bonnet 2 and is detachably connected to the sphere 3, and the top of the bonnet 2 and the valve stem 4 are sleeved A valve stem packing 10 is set, and a butterfly spring 13 is sleeved on the valve stem 4 to be pressed tightly on the valve stem packing 10. The connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com