Fin and wing aeroelasticity test device of high-speed wind tunnel

An aeroelastic, high-speed wind tunnel technology, applied in the direction of aerodynamic testing, measuring devices, testing of machine/structural components, etc., can solve the problem of insertion mechanism support stiffness affecting structural dynamic characteristics, difficult model system joint control test protection automation , slow response speed and other issues, to achieve the effect of compact structure, small flow field blockage and large load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

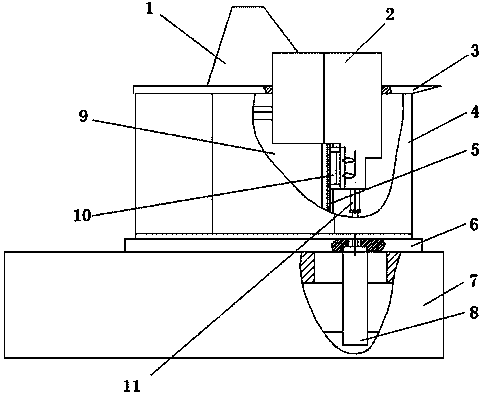

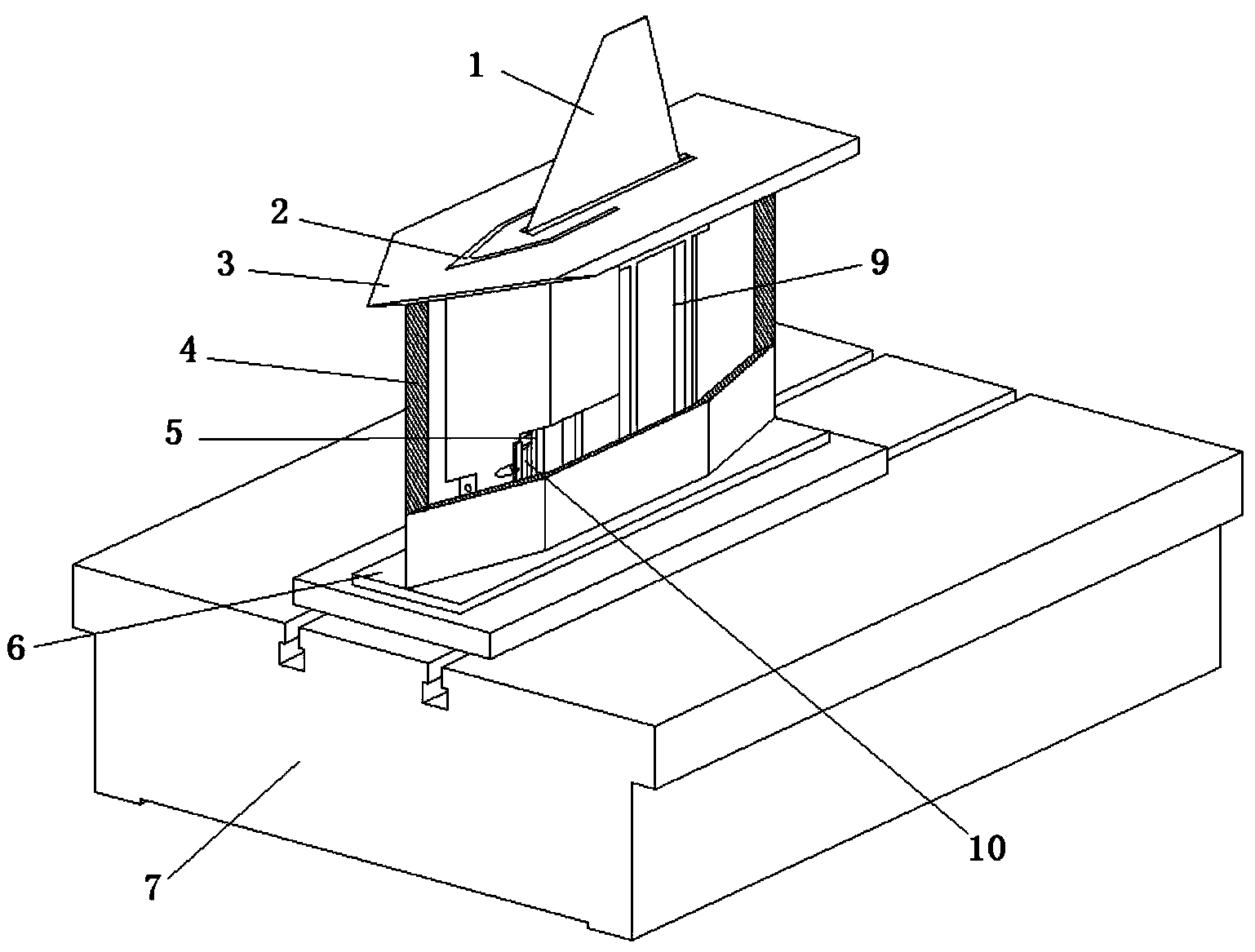

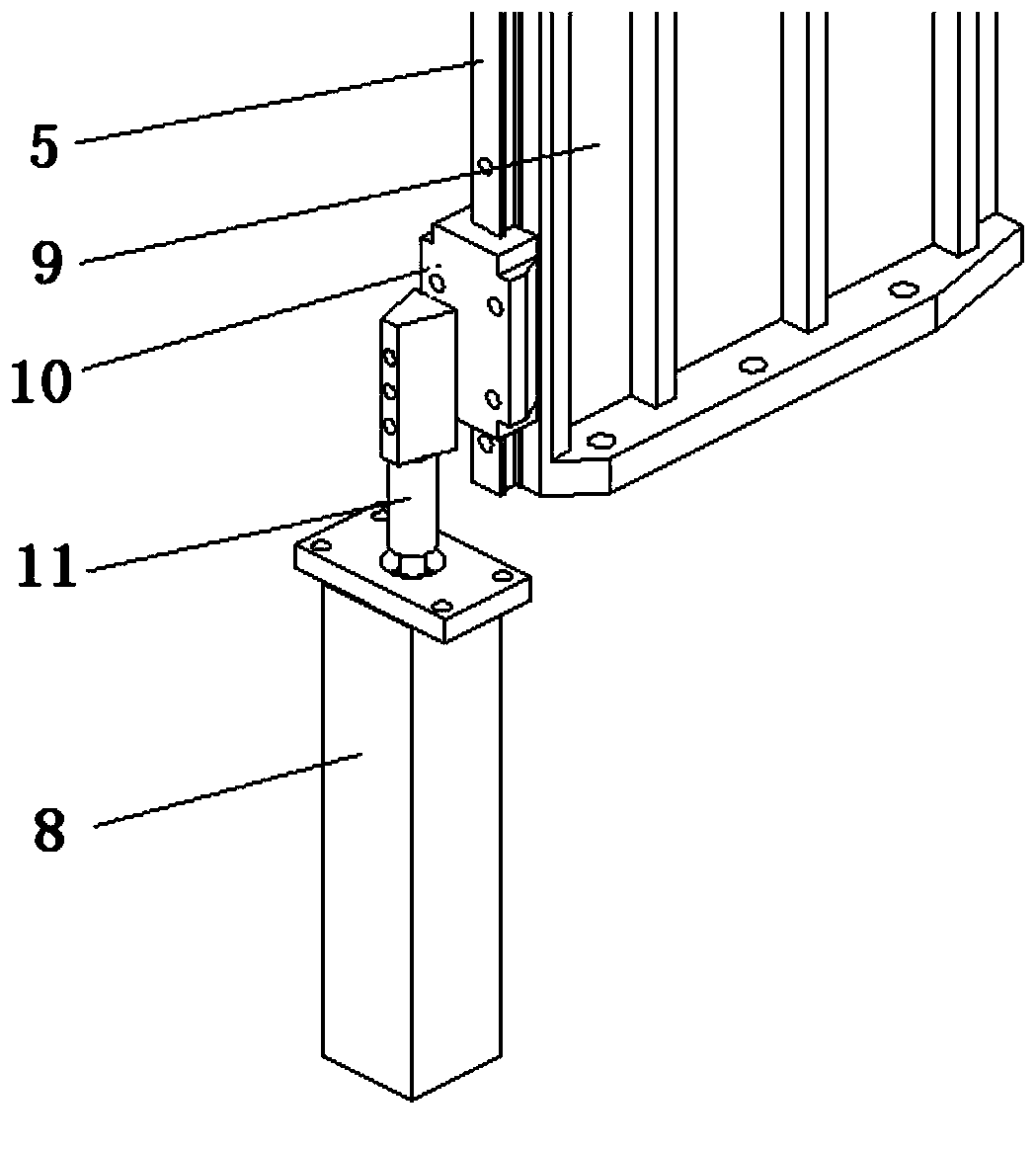

[0026] figure 1 It is a schematic diagram of the aeroelastic test device for rudder airfoil in a high-speed wind tunnel. In the figure 1 is a model (rudder surface model or airfoil model), 2 is a "V" protective cover, 3 is a reflector, 4 is a support baffle, 5 is a Guide rail, 6 is a base, 7 is a bottom platform, 8 is a cylinder, 9 is a model support, 10 is a guide rail slider, and 11 is a cylinder joint.

[0027] Such as figure 1 , 2 As shown, the model 1 (for the rudder surface model or the airfoil model) is installed on the model support 9, and the rudder shaft support form of the rudder surface model 1 or the airfoil model 1 is realized by installing different clamps on the model support 9. The form of root support is described below by taking the rudder surface model as an example.

[0028] The rudder surface model 1 is not connected with the reflector 3 and there is a suitable gap between the reflector 3 and the reflector 3 . The reflector 3 provides the root flow fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com