Production line management control system

A production line management and control system technology, applied in the field of control, can solve the problems of pairing monitoring, slow delivery, unclear delivery responsibility, etc., to reduce errors or omissions, avoid information lag, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

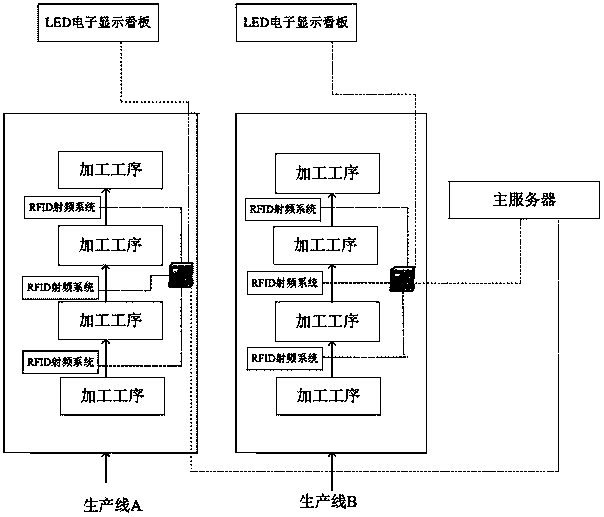

[0017] like figure 1 As shown, the present invention provides a production line management control system, including:

[0018] The main server is equipped with an ERP system. Through the RFID radio frequency system, the production line control management and quality management are combined with the ERP system. The production capacity status, material preparation status, customer order information, etc. of the production line site will be recorded in the ERP system. And displayed on the LED electronic display board in real time, managers can also query and manage in real time;

[0019] Common host, each production line is equipped with one or more public hosts, the public host on each production line communicates with an LED electronic display board, and each production line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com