Vibration control device and control method therefor

A vibration damping device and control method technology, applied in the direction of mechanical vibration control, shock absorber, non-electric variable control, etc., can solve the problems of high cost, amplitude amplification, vibration amplification, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

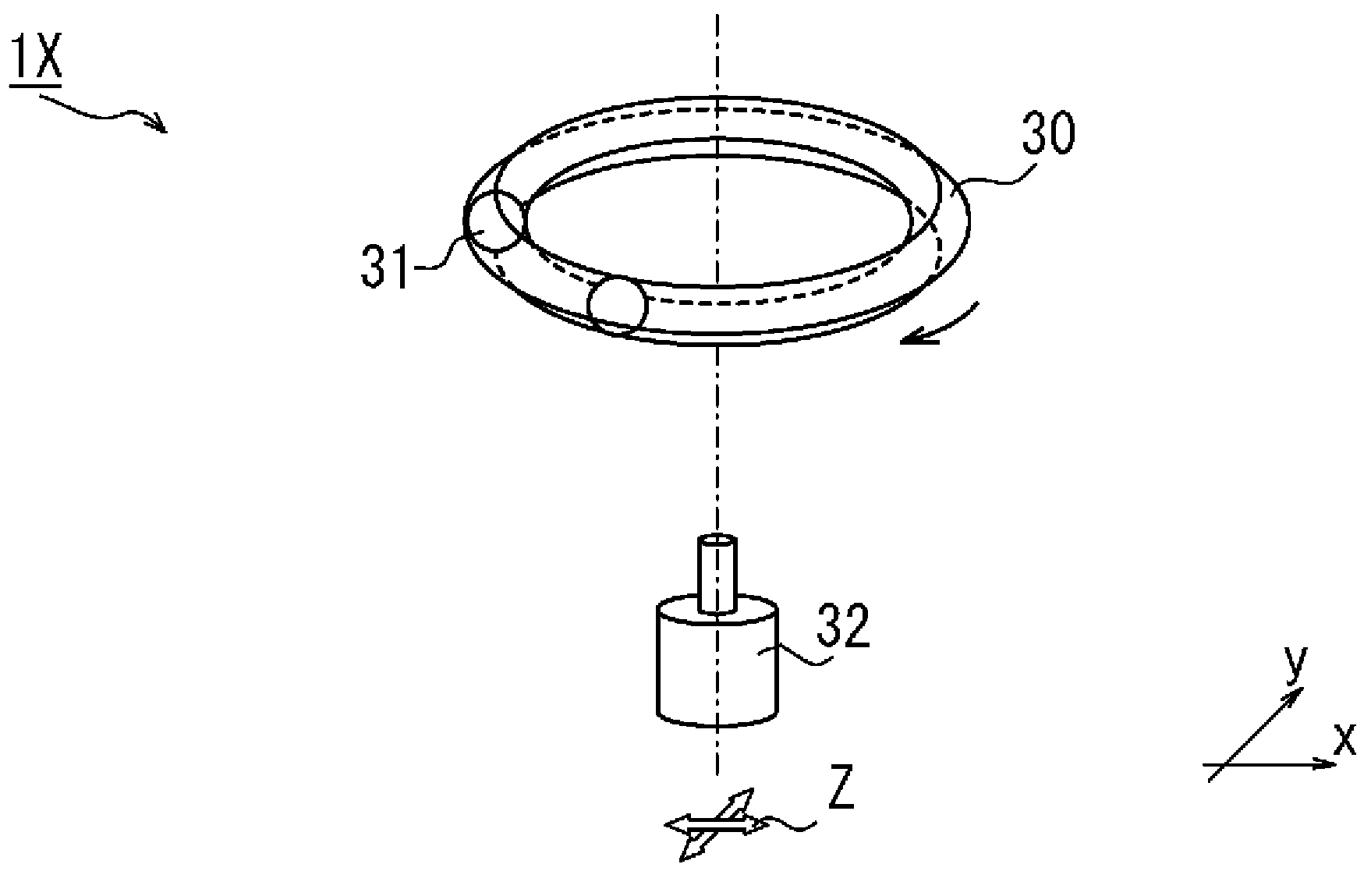

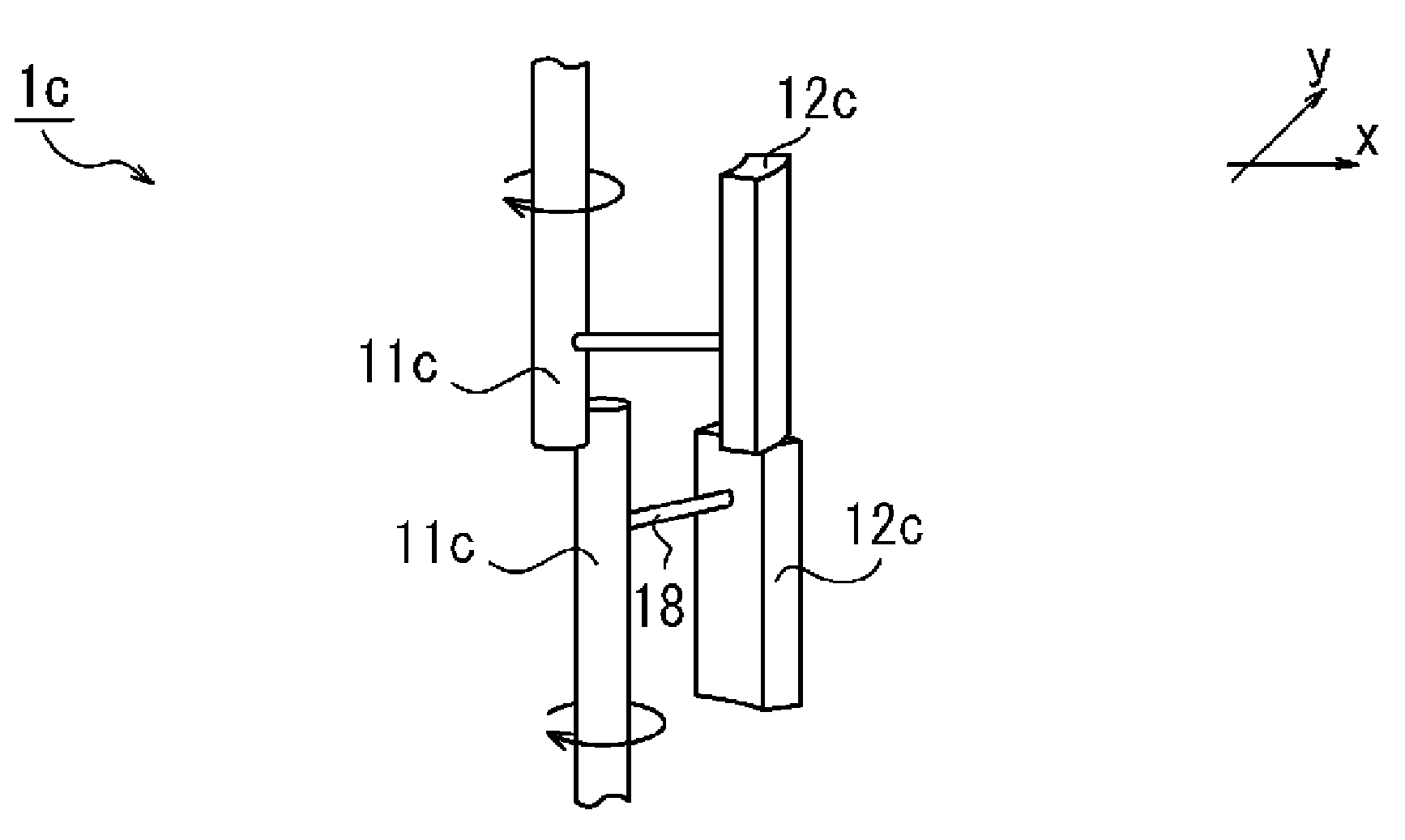

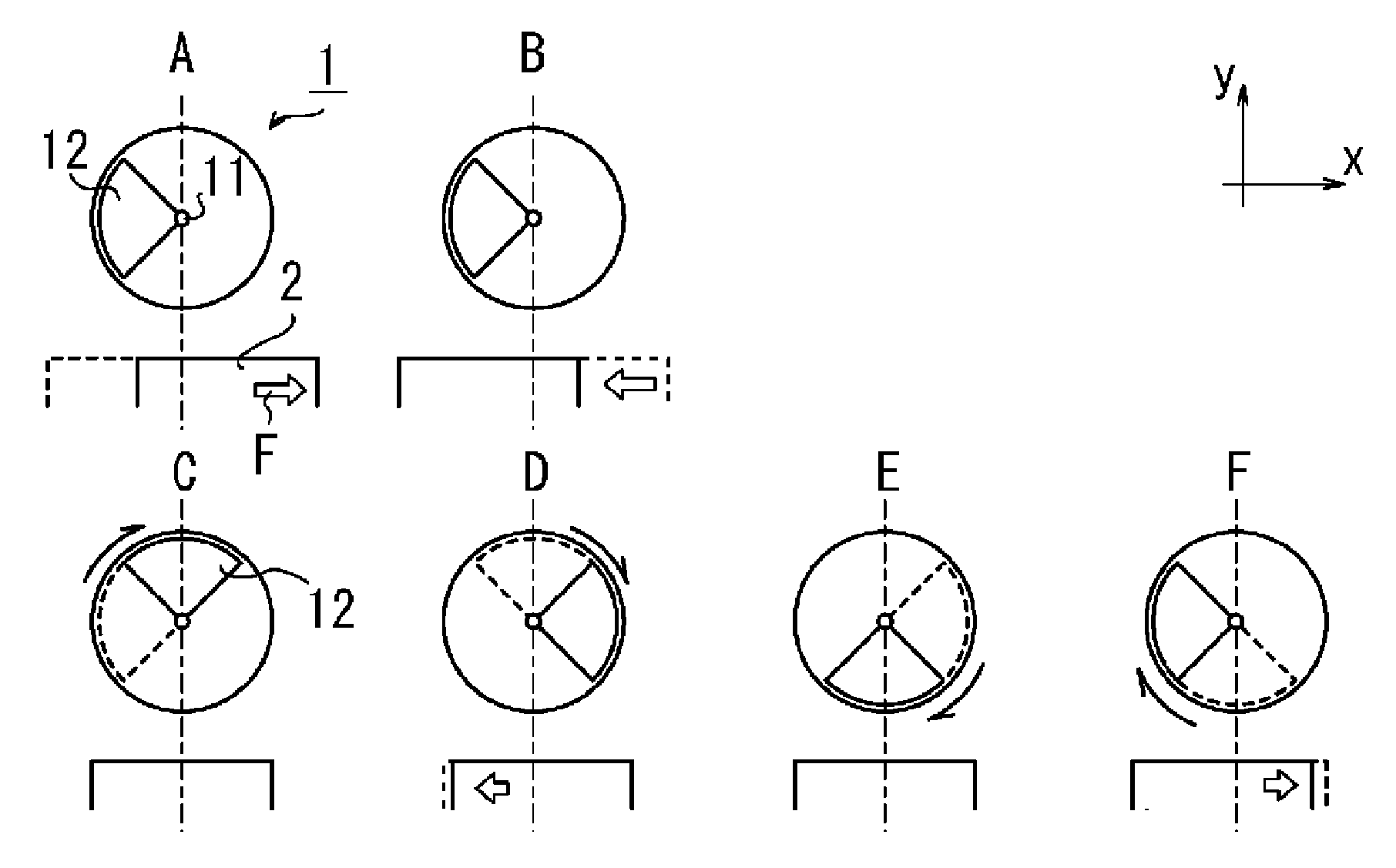

[0026] Below, while referring to the attached Figure 1 A vibration damping device according to an embodiment of the present invention will be described. In particular, a vibration damping device installed in a marine diesel engine (hereinafter referred to as a vibrating body) will be described as an example. exist figure 1 The outline of the damping device 1 according to the embodiment of the present invention is shown in . The damping device 1 has a rotating shaft 11, a mass body 12 fixed on the rotating shaft 11, a housing 15 for protecting the mass body 12, a clutch 14 arranged on the rotating shaft 11, and a starter for starting the mass body 12 via the clutch 14. Devices (such as electric motors)13. Furthermore, the damping device 1 has a base plate 16 via which it is arranged on the vibrating body (for example a diesel engine) 2 . The mass body 12 is formed in a thick fan shape (hereinafter referred to as a disk-shaped mass body). The clutch 14 is configured to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com