Power conversion device

A technology of power conversion device and power module, which is applied in the direction of converting irreversible DC power input into AC power output, support structure installation, cooling/ventilation/heating renovation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

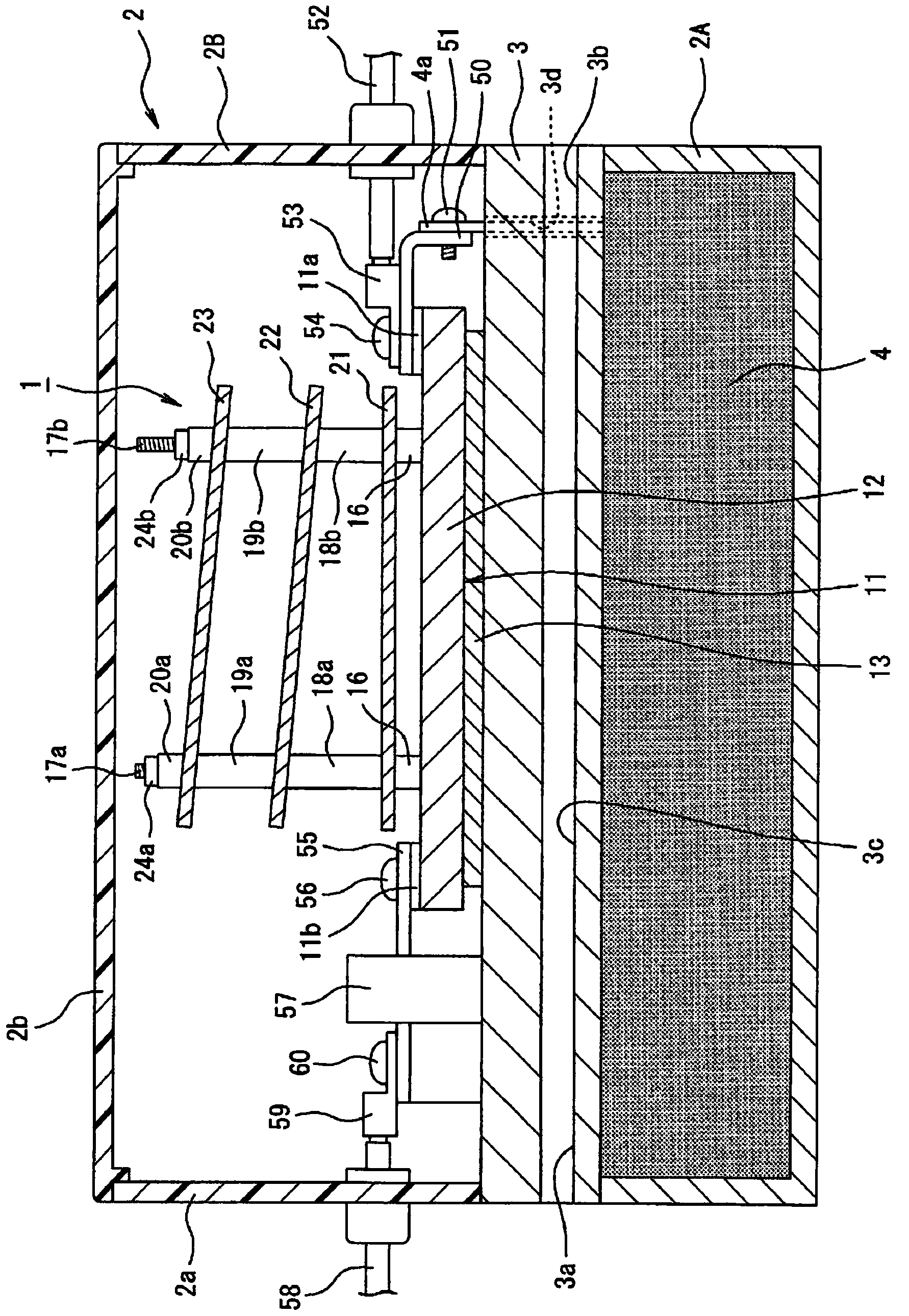

Examples

Embodiment approach 6

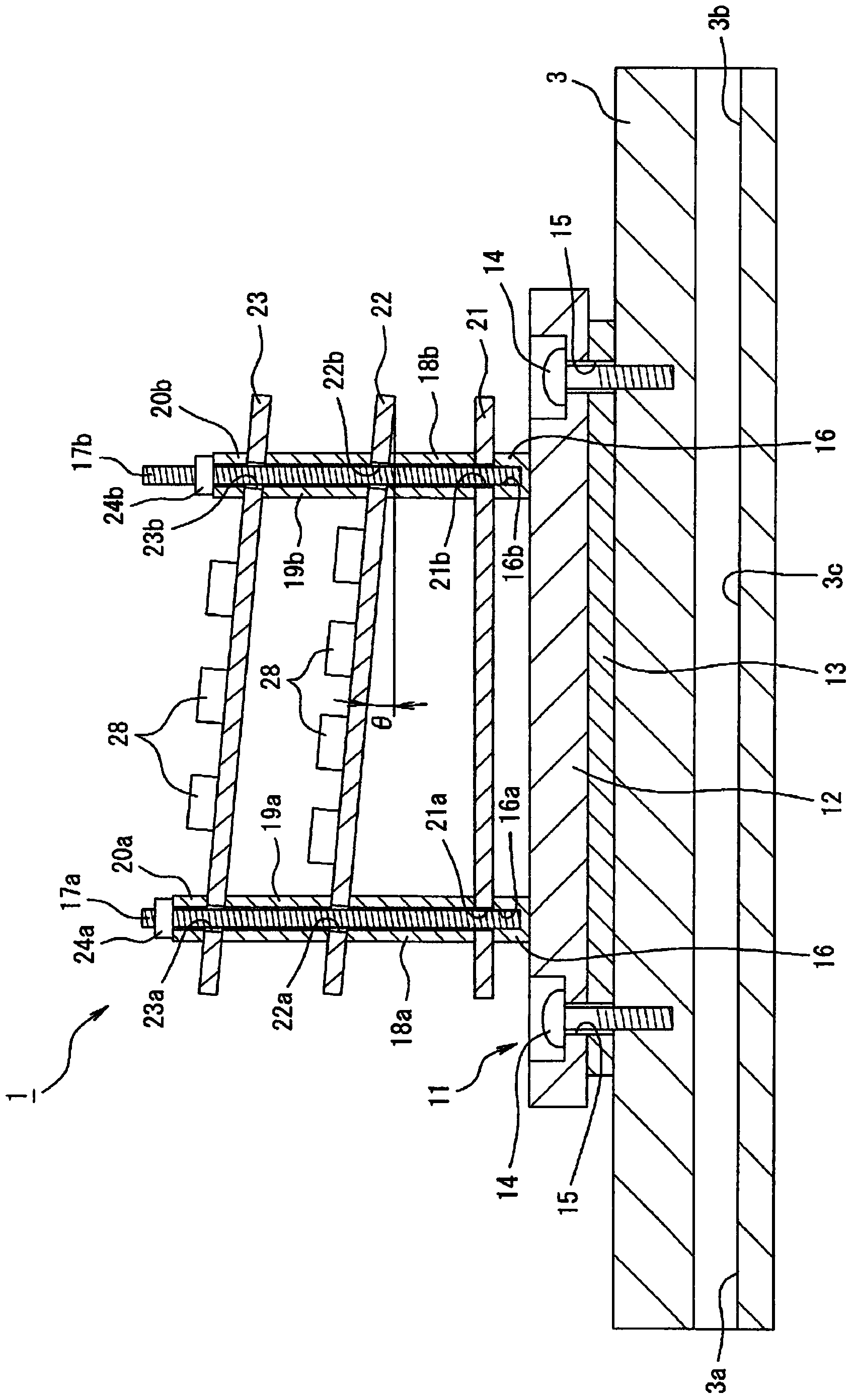

[0158] According to Embodiment 6, the control circuit board 22 and the power circuit board 23 on which the heating circuit components are mounted are supported by the heat conduction support plate portions 62 a and 65 a via the heat conduction members 61 and 64 , respectively, and these heat conduction support plate portions 62 a and 65 a pass through the heat conduction support plate portions 62 a and 65 a. The support side plate portions 62c and 65c are connected to the heat sink 3 . As a result, the heat generated by the heating circuit components mounted on the control circuit board 22 is conducted to the heat conduction support plate portion 62 a through the heat conduction member 61 , and is conducted from the heat conduction support plate portion 62 a to the cooling body 3 via the heat conduction support side plate portion 62 c. To dissipate heat.

[0159] Similarly, the heat generated by the heating circuit components mounted on the power circuit board 23 is conducted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com