High-efficiency albumen powder drying device

A drying device, protein powder technology, applied in protein food processing, protein food ingredients, spray evaporation, etc., to achieve the effect of easy control of gas temperature and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

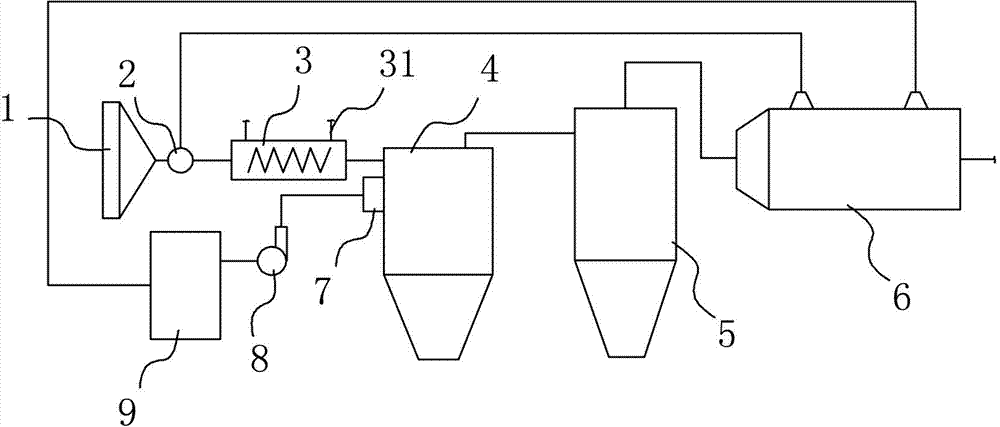

[0012] like figure 1 As shown, a protein powder high-efficiency drying device includes a drying tower 4, a feeding device, a gas generating device and a discharging device, the drying tower 4 has a feeding port, a discharging port and a gas injection port, and the gas generating device includes sequentially connected Filter 1, blower 2 and air heater 3, the outlet of air heater 3 is connected to the jet port, wherein, the discharge device includes cyclone separator 5 and preheater 6, discharge port, cyclone separator 5 and preheater 6 are connected in sequence; the feeding device includes a storage tank 9, a feed pump 8 and a sprayer 7 connected in sequence, the air inlet of the preheater 6 is also connected with the outlet of the blower 2, and the gas outlet is communicated with the storage tank 9.

[0013] In this embodiment, the inlet and outlet of the shell side of the preheater 6 communicate with the outlet of the blower 2 and the storage tank 9 respectively, the tube sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com