Stirring paddle used for paraffin production stirring equipment

A technology of stirring equipment and stirring paddles, which is applied in the direction of mixer accessories, dissolving, mixers, etc., can solve the problems of inconvenient cleaning of stirring paddles, increase in viscosity, and decrease in reaction rate, etc., and achieve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

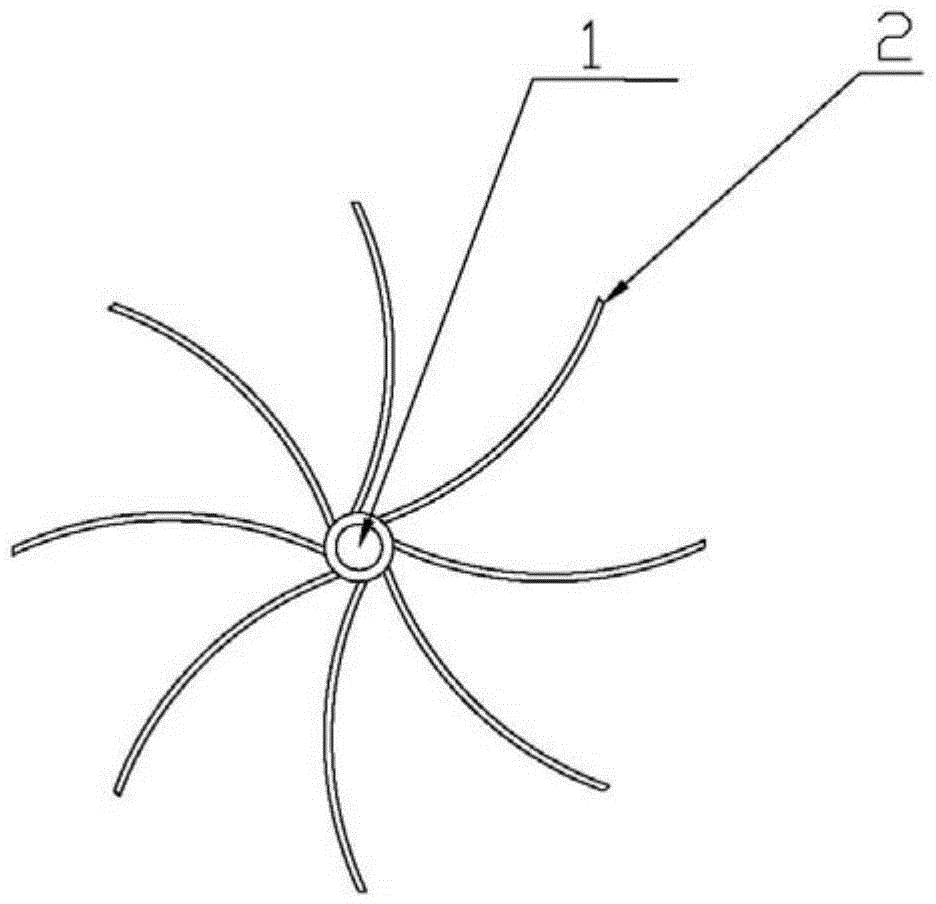

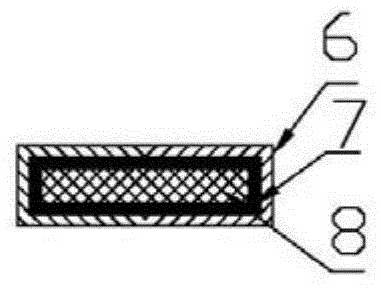

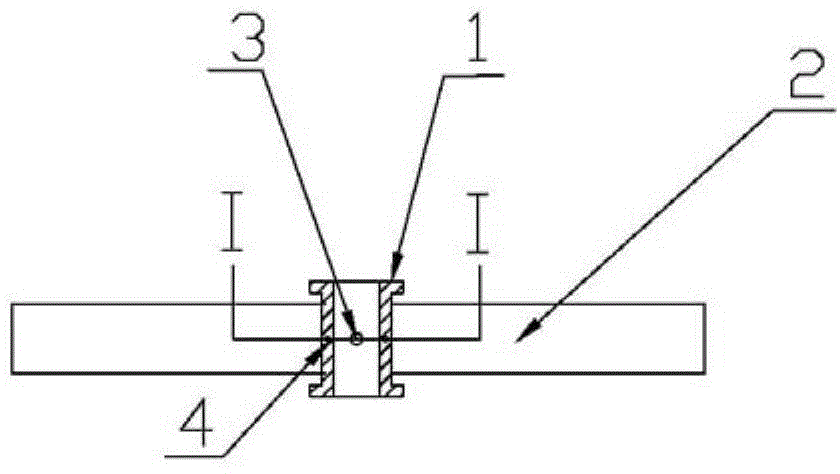

[0016] A stirring paddle for paraffin production stirring equipment, the stirring paddle includes a shaft sleeve 1 and 8 paddles 2 fixed on the outer circumference of the shaft sleeve 1; the paddle 2 includes a hollow paddle body 7 and covers the paddle The corrosion-resistant layer 6 on the outer surface of the blade body 7 is filled with a heating net 8 in the inner cavity of the blade body 7; the bushing 1 includes a bushing body 5, and a wire for placing wires is arranged inside the bushing body 5. The annular cavity 4, and at least two through holes 3 for pulling out the wires are opened on the inner wall of the sleeve body 5 where the annular cavity 4 is located. The material of the corrosion-resistant layer 6 is carbon fiber composite material. The inner wall of the blade body 7 is provided with an insulating layer. The inner wall of the annular cavity 4 is provided with an insulating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com