A titanium concentrate classifying device and its classifying method

A classification device and classification method technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. To achieve the effect of improving the utilization effect, targeted and efficient classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the titanium concentrate classification device and classification method of the present invention will be described in detail with reference to the drawings.

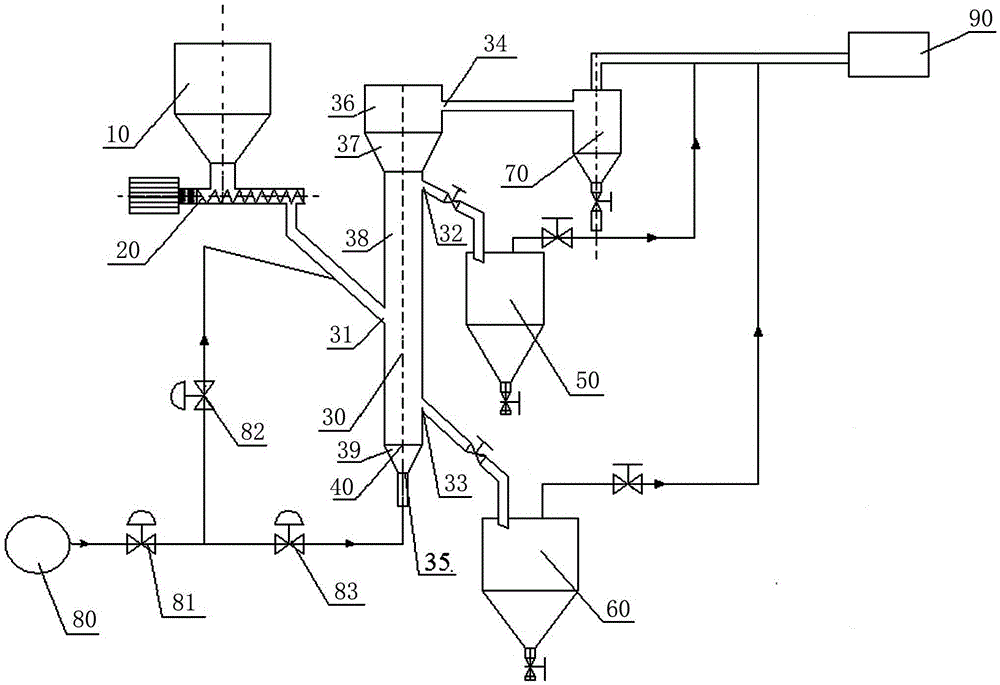

[0028] figure 1 It is a schematic diagram of the structure of a titanium concentrate classification device according to an exemplary embodiment of the present invention.

[0029] Such as figure 1 As shown, according to an exemplary embodiment of the present invention, the titanium concentrate classification device includes a high-level silo 10 connected by a pipe, a screw feed unit 20, a fluidized classification unit 30, a gas supply unit, and coarse-grained titanium Concentrate receiving unit 50, fine-grained titanium concentrate receiving unit 60, and fine-grained titanium concentrate receiving unit.

[0030] The structure and function of each unit in the classification device will be described in detail below.

[0031] Among them, the high-position silo 10 is used to temporarily store or hold the titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com