Horizontally-hung type cutting-punching point connection combined female die device

A technology of cutting pressure points and dies, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high manufacturing cost, material fatigue, inconvenient maintenance, etc., and achieve high service life, high compressive strength, running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

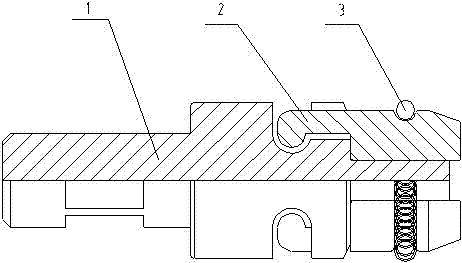

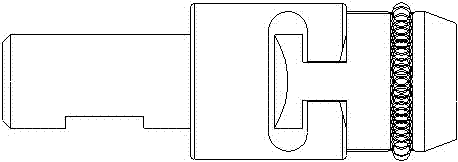

[0039] See attached figure 1 , 2As shown in , 3, each view reflects the structure of the combined die device connected by the horizontal cutting pressure point. Combined into a die device; this die device is matched with the corresponding punch to have the functions of cutting and separation, stretching deformation, extrusion and inlay at the connection point of the plate, and can complete the connection of a certain part of the plate at one time. In terms of structural design, the number of accessories should be reduced as much as possible, and the pressure center of the main body should not be equipped with a leaky slot structure, so as to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com