A High Precision Thick Foil Scissors Axis System

A technology of cutter shaft and system device, which is applied in the direction of cutter, shearing device, metal processing, etc. for shearing machine device, can solve the problems of low precision, large accumulated error, friction and heating, etc., to ensure the accuracy of radial clearance , the effect of reducing difficulty and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

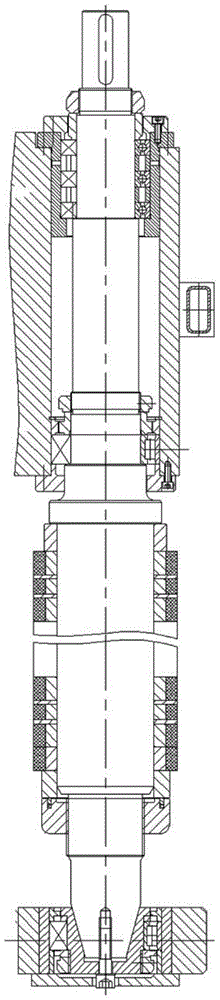

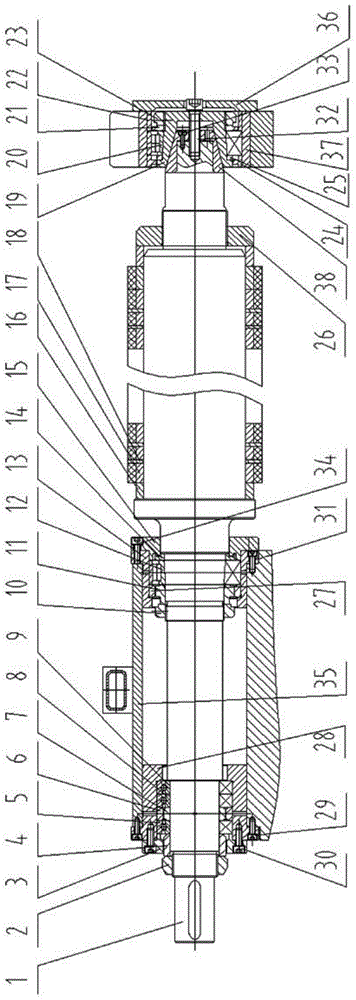

[0018] The cutter shaft system device realized by the present invention is as figure 1 As shown, it specifically includes cutter shaft 1, nut 1 2, bearing cap 3, spacer 1 4, angular contact ball bearing 5, spacer ring 1 6, spacer ring 2 7, angular contact ball bearing 2 8, angular contact ball bearing Three 9, nut two 10, spacer two 11, cylindrical roller bearing one 12, bearing housing one 13, spacer three 14, gland 15, reference ring 16, spacer ring 17, disc cutter 18, inner taper sleeve 19 , Cylindrical roller bearing two 20, spacer four 21, spacer five 22, nut three 23, spacer six 24, spacer seven 25, nut four 26, spacer eight 27, bearing seat two 28, screw one 29, Screw two 30, screw three 31, screw four 32, screw five 33, screw six 34, box body 35, end cover 36, bearing seat three 37, outer taper sleeve 38. Among them, the cutter shaft 1 is a forged integral type, and the rear end of the cutter shaft 1 is a cylindrical surface; the rear end support bearing of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com