Automatic spot welding tool, device and method for air conditioning unit bases

A technology for air-conditioning units and welders, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as low efficiency and complicated clamping operations, and achieve the effects of improving spot welding accuracy, fast clamping, and improving spot welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

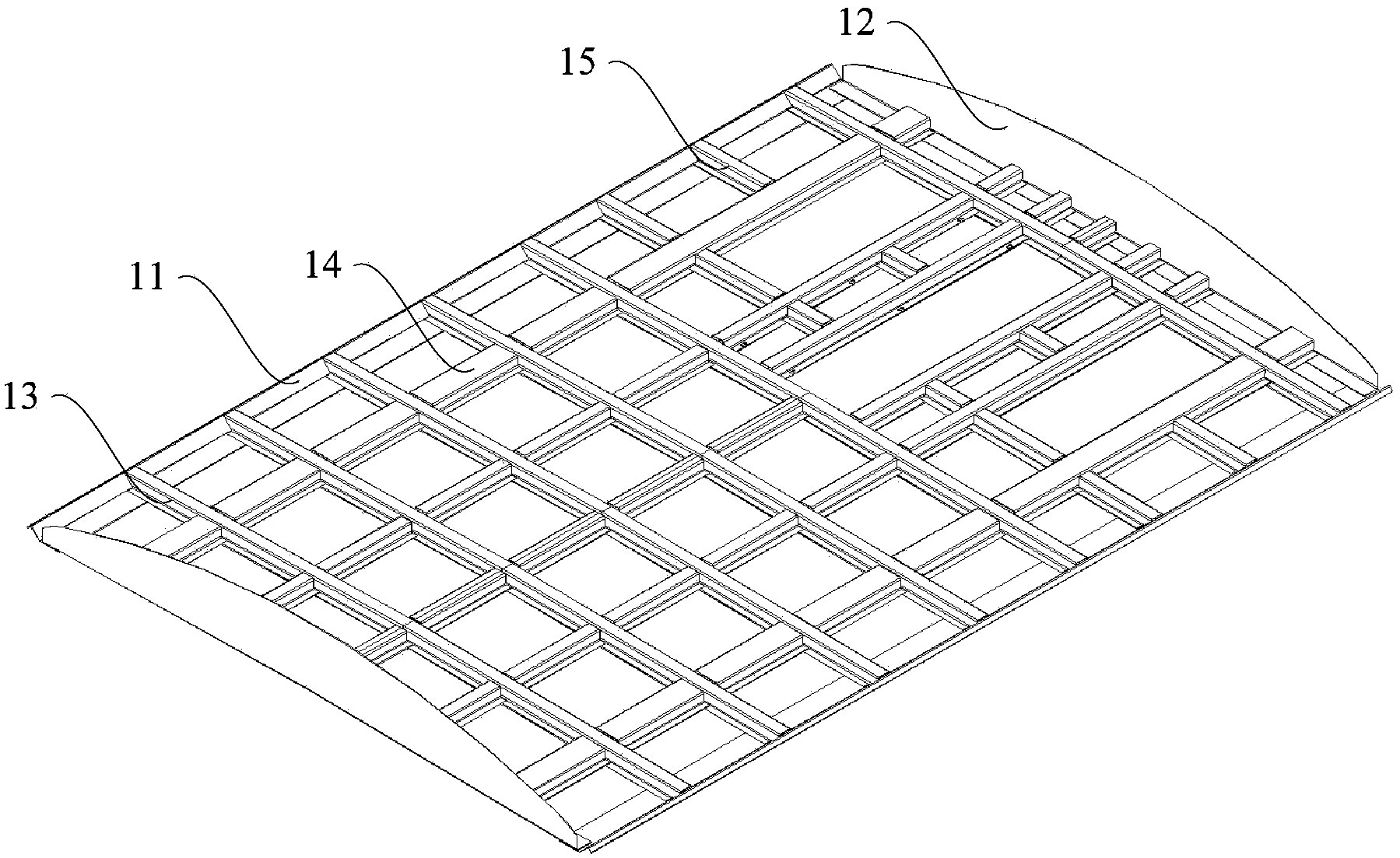

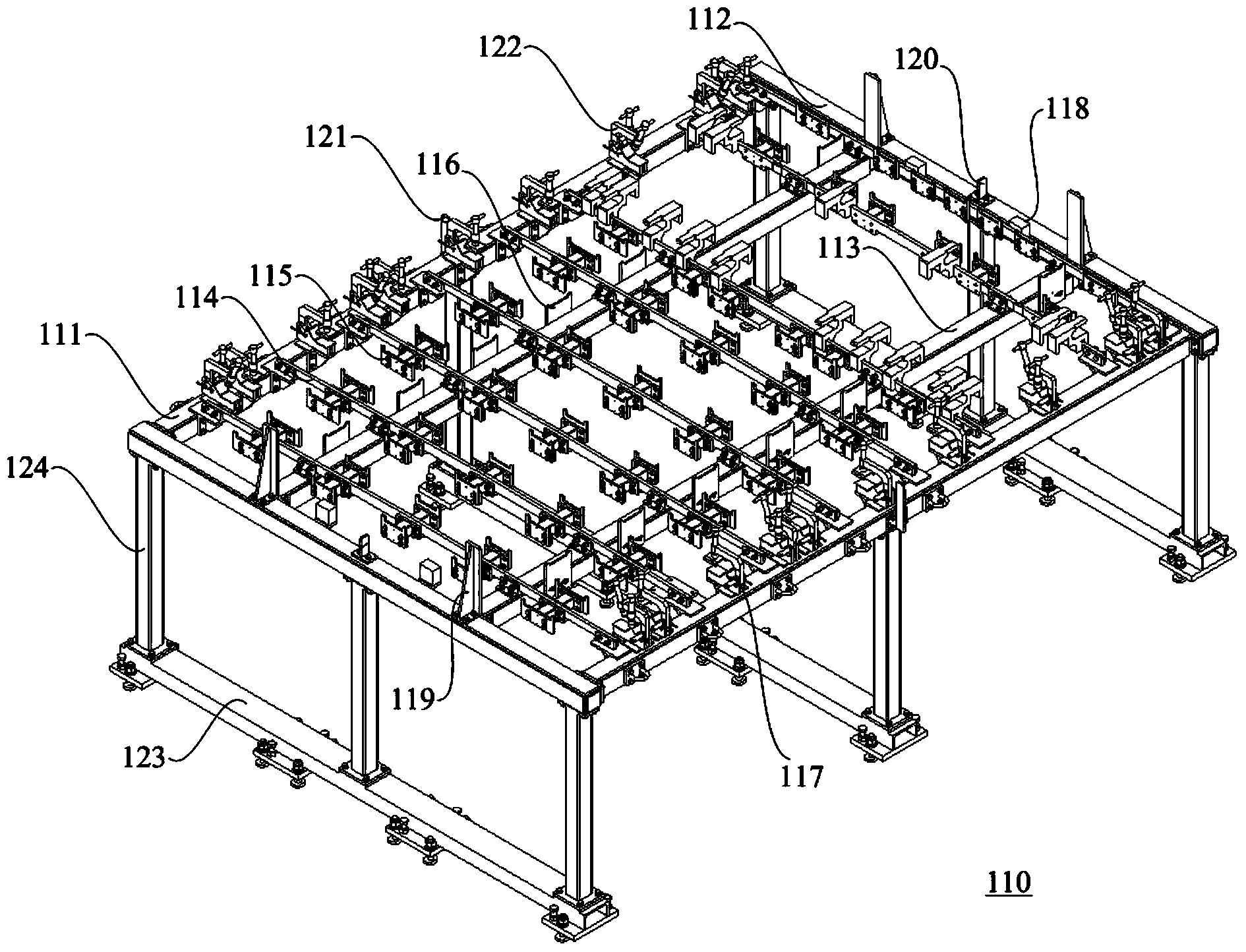

[0030] figure 2 The structural schematic diagram of Embodiment 1 of the automatic spot welding tooling for the air conditioner unit seat provided by the present invention, as shown in figure 2 As shown, the automatic spot welding tooling of the air conditioner unit seat in this embodiment includes a first sub-spot welding tooling 110; the first sub-spot welding tooling 110 includes two first side beams 111 and two first beams 112 The first rectangular frame, the two middle longitudinal beams 113 arranged parallel to the first side longitudinal beams 111, the small longitudinal beam positioning seats 114 arranged parallel to the two first cross beams 112, and any one of the small longitudinal beam positioning seats 114 The small longitudinal beam positioning plate 115, the beam positioning plate 116 arranged on any one of the middle longitudinal beams 113, the beam compactor 117 arranged on any one of the first side beams 111; each of the two first beams The first beam 112 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap