Welding assembly equipment

A kind of equipment and clamping technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem that the production efficiency cannot be improved, there is no equipment for welding of six support seats, and the position and size of the six support seats cannot be guaranteed and other problems, to achieve the effect of convenient structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

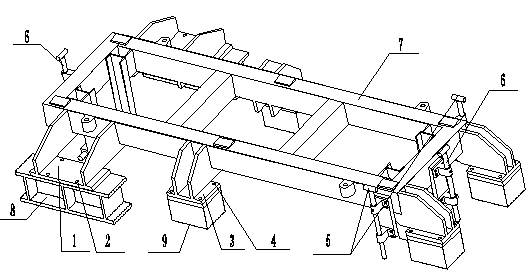

[0009] figure 1 It is a structural schematic diagram of the present invention, including a clamp body 7 in the figure, horizontal positioning rods 5 are provided on the upper and lower sides of the clamp body 7, longitudinal positioning rods 6 are provided on the front and rear sides of the clamp body 7, and the clamp body The upper and lower sides of 7 are also provided with a large positioning plate 1 and a small positioning plate 3, the long support seat 8 that needs to be installed is connected by bolts 2 on the large positioning plate 1, and the small positioning plate 3 is connected by bolts 4 and needs to be installed. The short support seat 9. There are four installation positioning holes on the large positioning plate 1 and the small positioning plate 3, the large positioning plate 1 and the small positioning plate 3 and the fixing bolts 2 and bolts 4 are all installed on the clamp body 7, making it a whole, the clamp body 7 Designed as a frame structure, it not only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com