Automatic welding mold for automobile steering system parts

A technology of automobile steering system and automatic welding, which is applied in vehicle parts, welding equipment, welding equipment, etc., can solve the problems of ineffective detection of workpiece production and quality, low operation efficiency, etc., and achieve the effect of improving quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

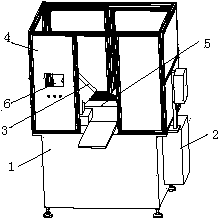

[0012] Combine below Figure 1 to Figure 4 Specific description embodiment:

[0013] Such as figure 1 As shown, the automatic welding equipment for automobile steering system components includes a frame 1, an electrical control box 2 is arranged on the side of the frame 1, and an electrical control system is housed in the electrical control box 2. The stroke positioning cylinders are connected to control the movement of the double-column welding machine 3. The double stroke positioning cylinders. A welding mold 5 and a double-column welding machine 3 are arranged on the top of the frame 1 , and the double-column welding machine 3 is arranged above the two sides of the welding mold 5 . The double column welding machine 3 includes two welding electrode heads 31 . The top of the frame 1 is provided with a protective cover 4, and the double-column welding machine 3 and the welding mold 5 are arranged inside the protective cover 4.

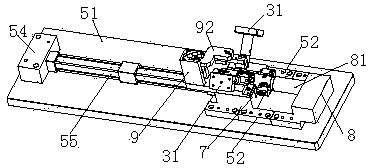

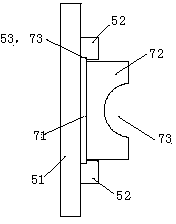

[0014] Such as figure 2 and image 3 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com