A capping device for large-bore bottles

A large-diameter bottle and large-diameter technology, which is applied in the directions of transportation, packaging, and chute, can solve the problems of inability to detect large-diameter caps and be easily affected by human factors, and achieve the effect of high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

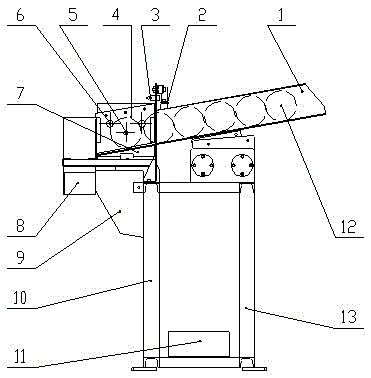

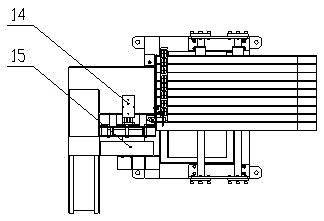

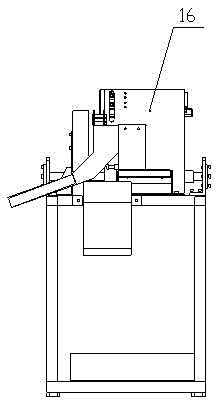

[0010] Such as figure 1 , 2 , 3, the upper cover device of the present invention includes a chute group 1, an induction frame 2, a sensor 3, a limit electromagnet 4, a bottle cap sensor 5, a plexiglass plate slideway 6, a lower baffle plate 7, and a chute 8 , Abandon cover bucket 9, frame 10, collection box 11, translation mechanism 12, the large diameter cover 13 of attached detection code, cylinder 14, detector 15, baffle plate 16, it is characterized in that frame 10 is provided with translation mechanism 12 1. The translation mechanism 12 is provided with a chute group 1, the upper part of the chute group 1 is provided with an induction frame 2, the induction frame 2 corresponds to the sensor 3, the sensor 3 is installed on the baffle plate 16, the chute is aligned with the plexiglass plate slideway 6, and the plexiglass plate slideway 6 Lower baffle plate 7 is arranged below, and lower baffle plate 7 links cylinder 14, and the lower baffle plate 7 lower part is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com