Automatic clamping mechanism for intelligent hanging system

A clamping mechanism and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of restricting smart home textile hanging systems, low work efficiency, irregular clamping, etc., to save manpower, improve work efficiency, Effect of clamping specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

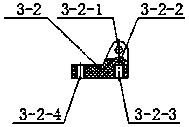

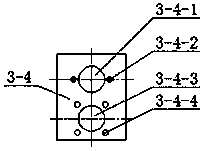

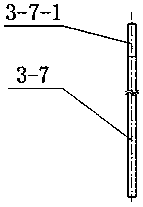

[0047] see Figure 1-10 , the automatic clamping mechanism for the intelligent hanging system in this embodiment includes a clamped 1 and a lifting mechanism, and the lifting mechanism includes a driving device and a cross bar 3-1. In this embodiment, the driving device is preferably a cylinder 3, The processing object clamped by the clamp 1 runs between the main rail and the branch rail of the intelligent home textile hanging system. The cylinder 3 is fixed on the ground through the fixed base 3-6. The workbench 2 is located between the clamp 1 and the cylinder 3 of the home textile. The table 2 is provided with an avoidance hole 2-1, and it is determined whether the base 3-6 is fixed to the ground depending on the situation in actual use. The upper edge in the contracted state, so that the processing object is in a flat state before clamping. The size of the workbench 2 is generally slightly larger than the processing object, and the workbench 2 can be made into a table-lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com