Emulsion recycling, purifying and regenerating equipment and method

A technology of emulsion circulation and regeneration equipment, which is applied in the field of emulsion purification in the process of mechanical processing, can solve the problems of low purification and separation efficiency of fine particles, complex emulsion purification equipment and equipment, and increase the difficulty of discharging waste liquid treatment. The effect of daily maintenance, small footprint and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

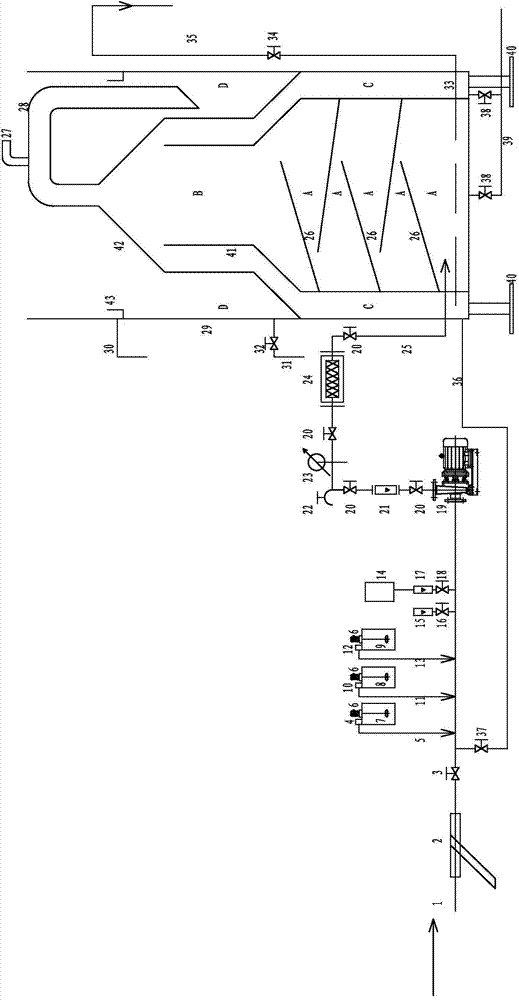

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] An emulsion circulation purification and regeneration equipment, comprising: Y-shaped filter 2, a dosing box device, a copolymerization separation device, a multiphase medium pump device and a gas device; the copolymerization separation device includes an outer shell 29, a mixing reaction inner cylinder 41, three The phase separator 42 and the overflow weir 43, the shell 29 is a cylindrical shell structure, and the side of the shell 29 is respectively equipped with a floating oil residue discharge pipe 30, an emulsion discharge pipe 31, an inlet of the emulsion to be purified and a discharge pipe of the emulsion after purification 35. There is an emptying pipe 39 at the bottom of the shell. The lower part of the mixing reaction inner cylinder 41 is a thick diameter straight cylinder, the upper part is a thin diameter cylinder, and the upper end of the upper thin ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap