A kind of high performance concrete prepared by using coal water slurry slag

A high-performance concrete and coal-water slurry slag technology, applied in cement production and other directions, can solve the problems of low density of coal-water slurry slag, poor concrete performance, large water absorption, etc., to reduce treatment costs, improve strength and durability. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method for high-performance concrete, comprising the steps of:

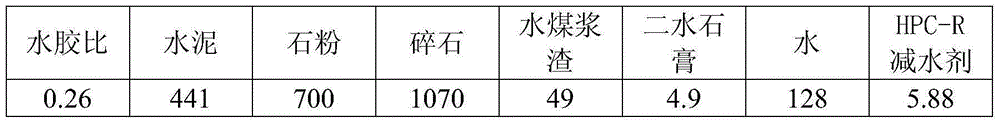

[0022] (1) Prepare raw materials such as cement, coal water slurry slag, water, stone powder, crushed stone, water reducing agent, water reducing agent and activator according to the formula in Table 1; the amount of coal water slurry slag accounts for 10% of the cementitious material %;

[0023] (2) Dry mix cement, coal water slurry slag, stone powder, gravel and activator for 60 seconds to obtain a dry mix;

[0024] (3) Pour the water reducing agent into water and mix to obtain the water agent, then add the water agent to the dry mix obtained in step (1), and stir for 120 seconds to obtain the high performance concrete.

[0025] Table 1 The ratio of raw materials per cubic meter of concrete (unit: kg / m 3 )

[0026]

[0027] The high-performance concrete prepared in this embodiment was tested according to the mechanical properties, and the test found that its 3-day compressive strength...

Embodiment 2

[0029] A preparation method for high-performance concrete, comprising the steps of:

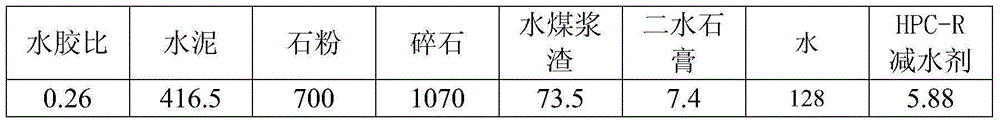

[0030] (1) Prepare raw materials such as cement, coal water slurry slag, water, stone powder, crushed stone, water reducing agent, water reducing agent and activator according to the formula in Table 2; the amount of coal water slurry slag accounts for 15% of the cementitious material %;

[0031] (2) Dry mix cement, coal water slurry slag, stone powder, gravel and activator for 80 seconds to obtain a dry mix;

[0032] (3) Pour the water reducing agent into water and mix to obtain the water agent, then add the water agent to the dry mix obtained in step (1), and stir for 150 seconds to obtain the high-performance concrete.

[0033] Table 2 The ratio of raw materials per cubic meter of concrete (unit: kg / m 3 )

[0034]

[0035] The high-performance concrete prepared in this embodiment was tested for mechanical properties, and the test found that its 3-day compressive strength was 70.2MPa,...

Embodiment 3

[0037] A preparation method for high-performance concrete, comprising the steps of:

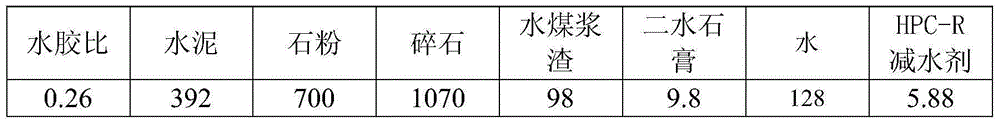

[0038] (1) Prepare raw materials such as cement, coal water slurry slag, water, stone powder, crushed stone, water reducer, water reducer and activator according to the formula in Table 3; the amount of coal water slurry slag accounts for 20% of the cementitious material %;

[0039] (2) Dry mix cement, coal water slurry slag, stone powder, gravel and activator for 90 seconds to obtain a dry mix;

[0040] (3) Pour the water reducing agent into water and mix to obtain the water agent, then add the water agent to the dry mix obtained in step (1), and stir for 180 seconds to obtain the high-performance concrete.

[0041] Table 3 The ratio of raw materials per cubic meter of concrete (unit: kg / m 3 )

[0042]

[0043] The high-performance concrete prepared in this embodiment was tested for mechanical properties, and the test found that its 3-day compressive strength was 69.2MPa, and the 28-da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com