Self-balancing cantilever construction method of long-span steel truss arch bridge and limit bearing of main pier

A technology of steel truss arch bridges and limit bearings, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as blocking the smooth hoisting of bridge deck components, expensive waterway maintenance and management costs, and compressed navigation headroom, etc., to achieve saving Direct engineering costs and waterway maintenance costs, high economy and practicality, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

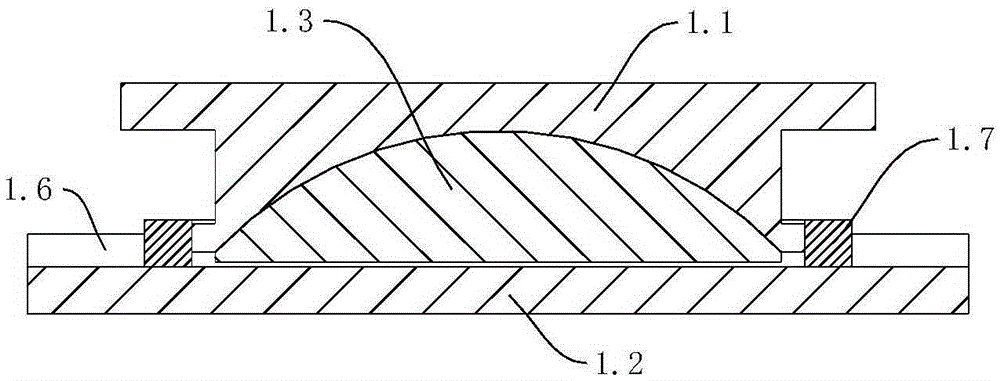

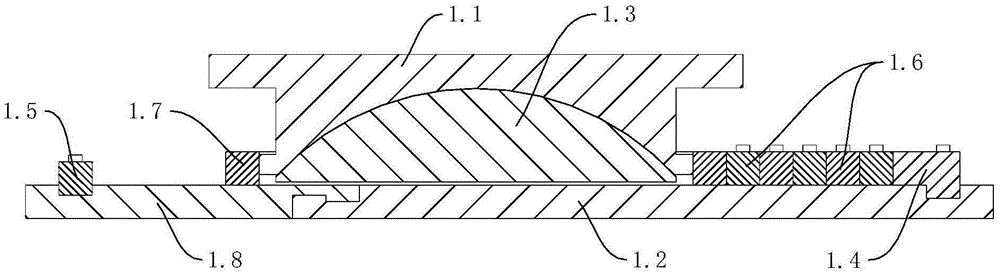

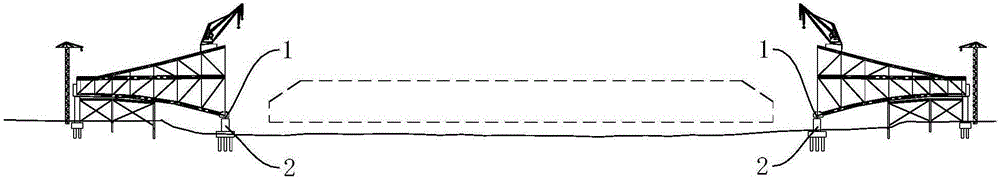

[0020] like figure 1 and image 3 As shown, the limit support of the main pier includes an upper support plate 1.1, a lower support plate 1.2, a spherical crown 1.3 is provided between the upper support plate 1.1 and the lower support plate 1.2, and the upper support plate 1.1 and the lower support plate 1.2 The spherical cap 1.3 is rotationally connected; the spherical cap 1.3 is slidingly connected to the lower support plate 1.2; along the sliding direction of the spherical crown 1.3, the lower support plate 1.2 is provided with a detachable first block 1.4 and the second stopper 1.5, the first stopper 1.4 and the second stopper 1.5 are respectively located on the opposite surface of the lower bearing plate 1.2, the spherical cap 1.3 and the upper bearing plate 1.1 can be positioned at the first stopper 1.4 and the second stopper 1.5; between the first stopper 1.4 and the upper bearing plate 1.5, there are a plurality of detachable adjustment pads 1.6. In order to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com