Building energy saving and heat preserving method and hollow block

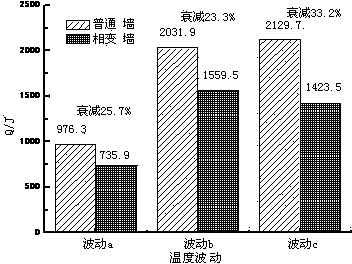

A building energy-saving and thermal insulation technology, applied in building materials and other directions, can solve problems such as poor weather resistance and poor safety, and achieve the effects of improving thermal comfort, low cost, and obvious energy-saving and thermal insulation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

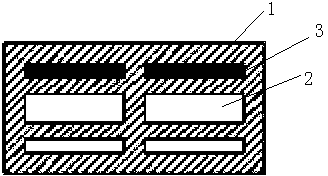

[0027] like Figure 2-3 shown.

[0028] A building energy-saving heat preservation method, it comprises the following steps:

[0029] First, mix capric acid and gypsum powder in a mass ratio of capric acid: gypsum powder = 1:1-2;

[0030] Secondly, at normal temperature (not exceeding 30°C), put the mixed capric acid and gypsum powder into the mold to make a phase-change gypsum board 3 with a size of 20×140×190 (unit mm), and the specific size can be customized according to the needs Self-designed;

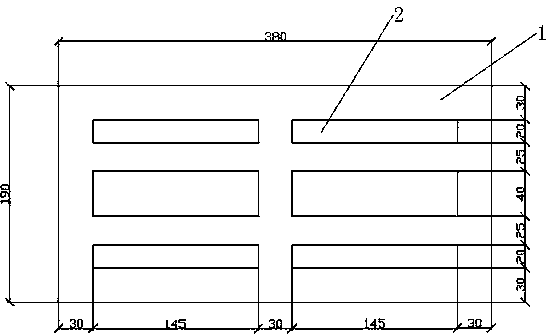

[0031] Third, use conventional methods to produce a top view such as figure 2 hollow concrete blocks as shown;

[0032] Fourth, put the phase change gypsum board 3 into figure 2 In the weight-reducing and heat-insulating hole 2 of the hollow concrete block shown on the outside of the wall, the two surfaces of the phase-change gypsum board are in close contact with the surface of the concrete hole wall to improve the heat conduction efficiency, as shown in figure 2 As show...

Embodiment 2

[0035] like image 3 shown.

[0036] An energy-saving hollow concrete block. The center of the concrete block 1 is provided with a number of weight-reducing and heat-insulating holes 2 along the height direction, and phase-change gypsum boards 3 are installed in at least a row of holes near the outside. The board 3 is made by mixing capric acid and gypsum, and the mass ratio of the two is capric acid: gypsum powder=1:1~2. The lower end of the life-reducing and heat-insulating hole 2 where the gypsum board 3 is installed is sealed with concrete to form a blind hole to prevent the phase-changed energy storage material from flowing out of the life-reducing and heat-insulating hole 2 . like figure 2 As shown, the size of the phase-change gypsum board can be length × width × height = 20 × 140 × 190, the unit is mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com