Dismantling and ejecting pin device of hydraulic support

A technology of hydraulic support and support frame, which is applied to pillars/supports, mining equipment, earth-moving drilling, etc. The structure is simple, and the effect of pulling out the pin and breaking the chain is avoided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

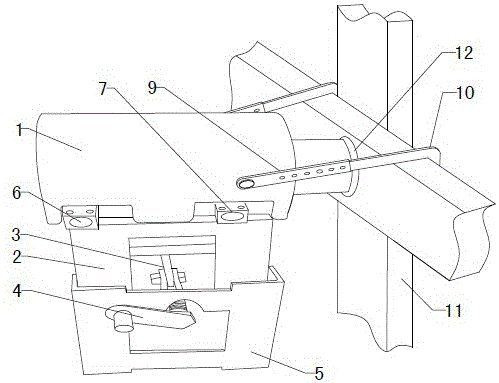

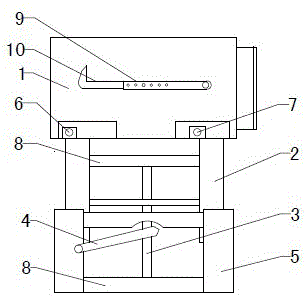

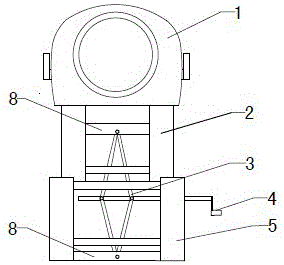

[0019] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0020] Refer to attached Figure 1~3 : the hydraulic pin ejection device of the present invention comprises an oil cylinder 1, a support frame 2, a screw jack 3, a rocking bar 4, a base 5, an adjusting rod 9, and a hook 10, and the oil cylinder 1 passes through the oil cylinder liquid inlet 6 and the oil cylinder liquid return port 7. Connect four rubber hoses. Hydraulic two-way locks are installed at the liquid inlet port 6 and the liquid return port 7 of the oil cylinder. The rubber hoses are connected to the external manual booster lever. The safety of withdrawing work; one end of the adjusting rod 9 is hinged on the extensible end of the oil cylinder 1, the other end of the adjusting rod 9 is sleeved outside the hook 10, and a plurality of equidistant screw holes are set on the adjusting rod 9 and the hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com