Method for improving wind turbine generator gearbox failure level judgment precision

A fault level, wind turbine technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as inaccurate fault level judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for improving the judgment accuracy of a wind turbine gearbox fault level involved in the present invention is based on the fusion analysis of the four fault parameters of the vibration signal of the gearbox bearing part, the wear particles in the gearbox oil, the gearbox oil temperature, and the gearbox bearing temperature The method is used to improve the accuracy of the judgment of the fault level of the gearbox of the wind turbine.

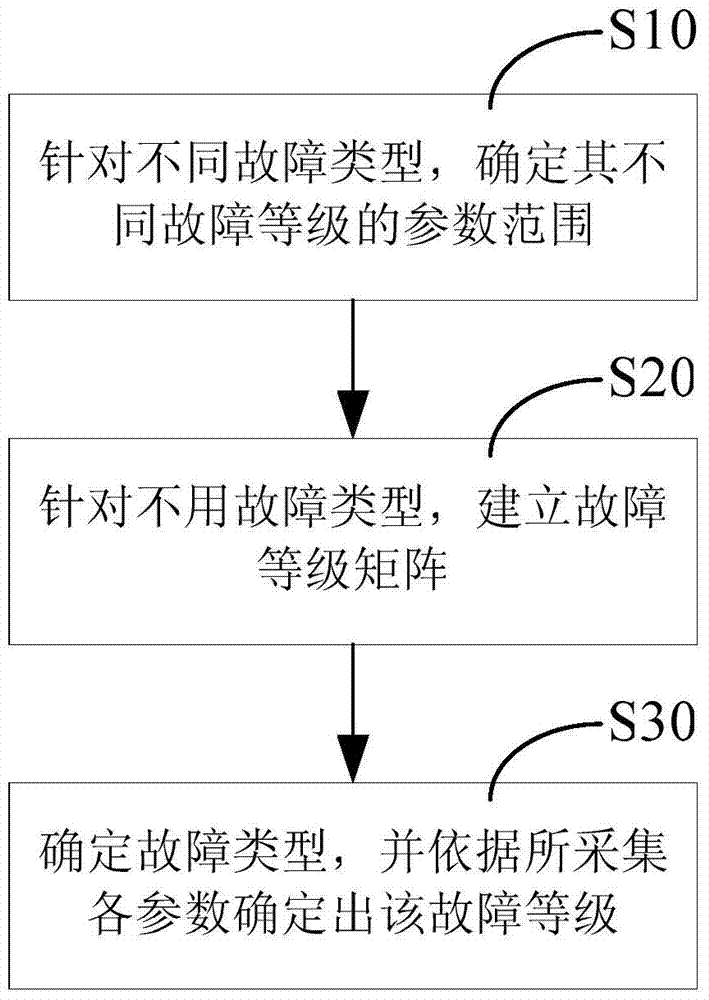

[0038] like figure 1 The schematic diagram shown, including the steps:

[0039] S10: According to the historical data, for different fault types, determine the fault parameter ranges of different fault levels.

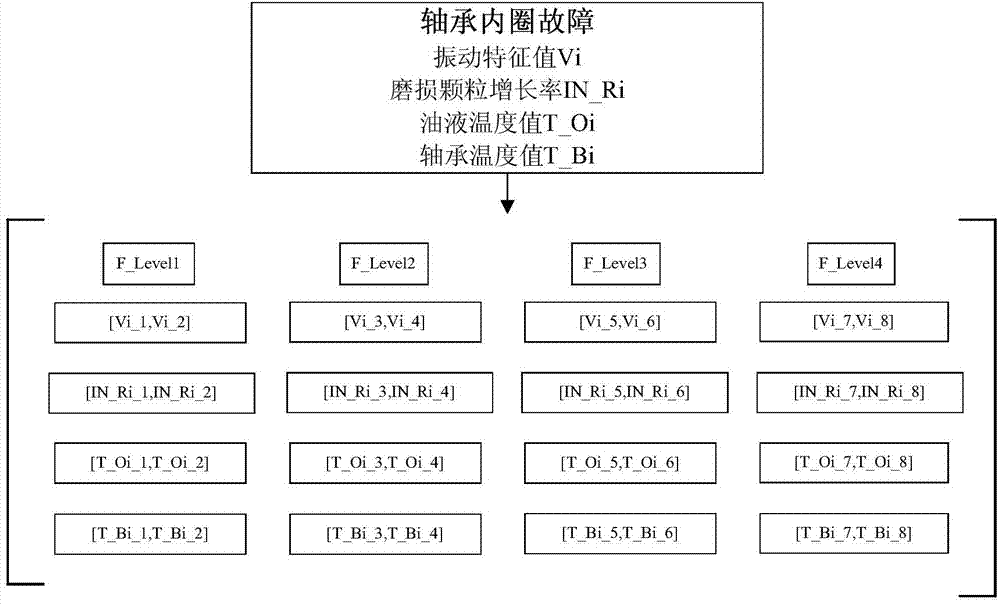

[0040] The faults of wind turbine gearboxes are commonly found in four parts: bearing inner ring, bearing outer ring, bearing rolling body and bearing cage. Therefore, the faults that appear in the above four locations are divided into four types of faults.

[0041] Further, the above four types all include four faul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com