Iron tower defect detection system based on aircraft and aircraft positioning method

A defect detection and aircraft technology, applied in the direction of optical testing flaws/defects, nan, electrical components, etc., can solve the problem of iron tower detection requiring manual climbing, inability to observe in all directions, etc., to reduce training costs, improve safety, technology The effect of request reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

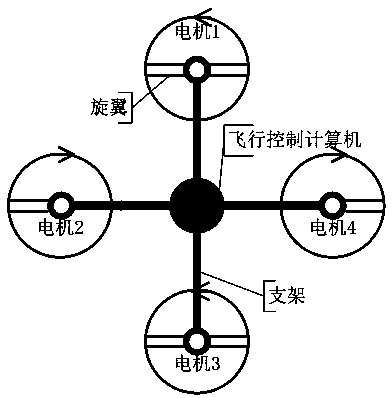

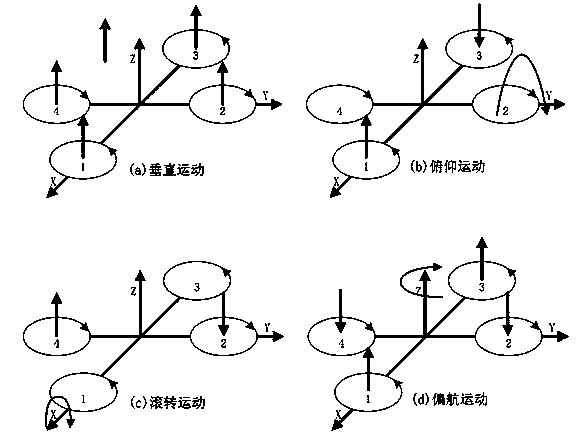

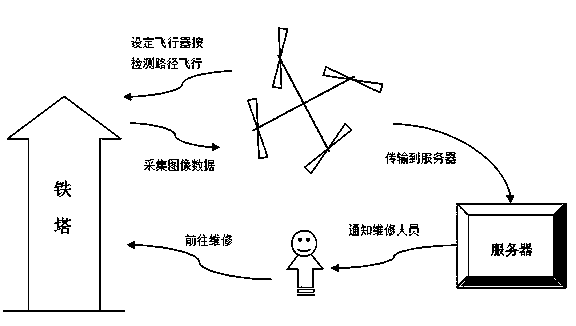

[0030] refer to figure 1 As shown, the system of the present invention uses a multi-rotor aircraft detection device equipped with a cloud platform instead of manual tower detection, uses the signal points set around to accurately locate, and accurately and stably detects the target position. The detection information is sent to the display in the hands of the operator in real time. For the situation that needs maintenance, it can be sent to the company's website immediately, and the maintenance personnel will be reminded to repair. Thereby reducing personnel scheduling, reducing maintenance costs and improving maintenance efficiency.

[0031] In order to solve the defects of the existing methods, the present invention provides a flow chart for realizing an aircraft positioning method in an aircraft-based iron tower defect detection syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com