Integrated sample needle loading and stirring system

A technology of stirring system and sample needle, which is applied in the field of integrated sample needle adding and stirring system, can solve the problems of complex structure and time-consuming, and achieve the effect of simple and stable equipment mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

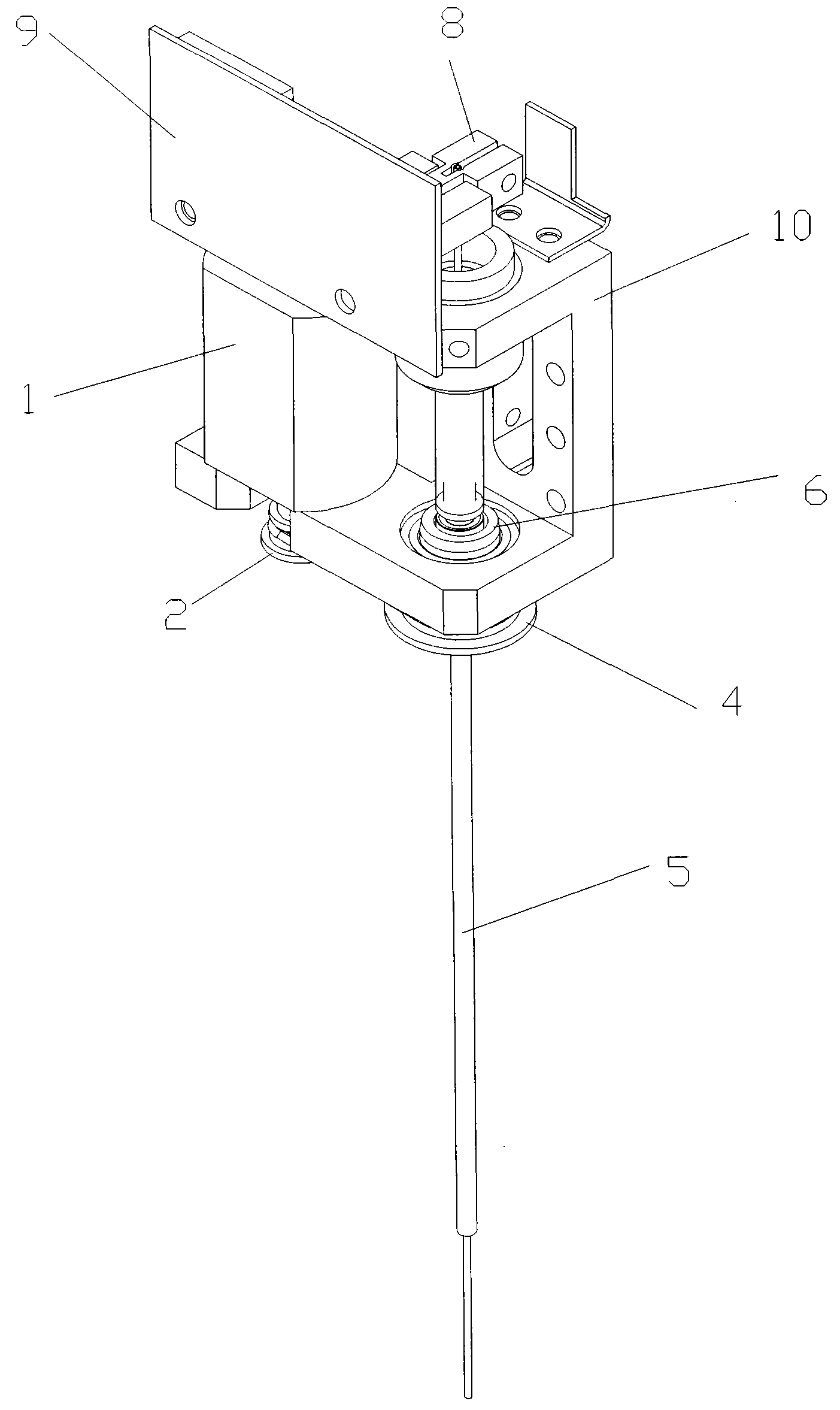

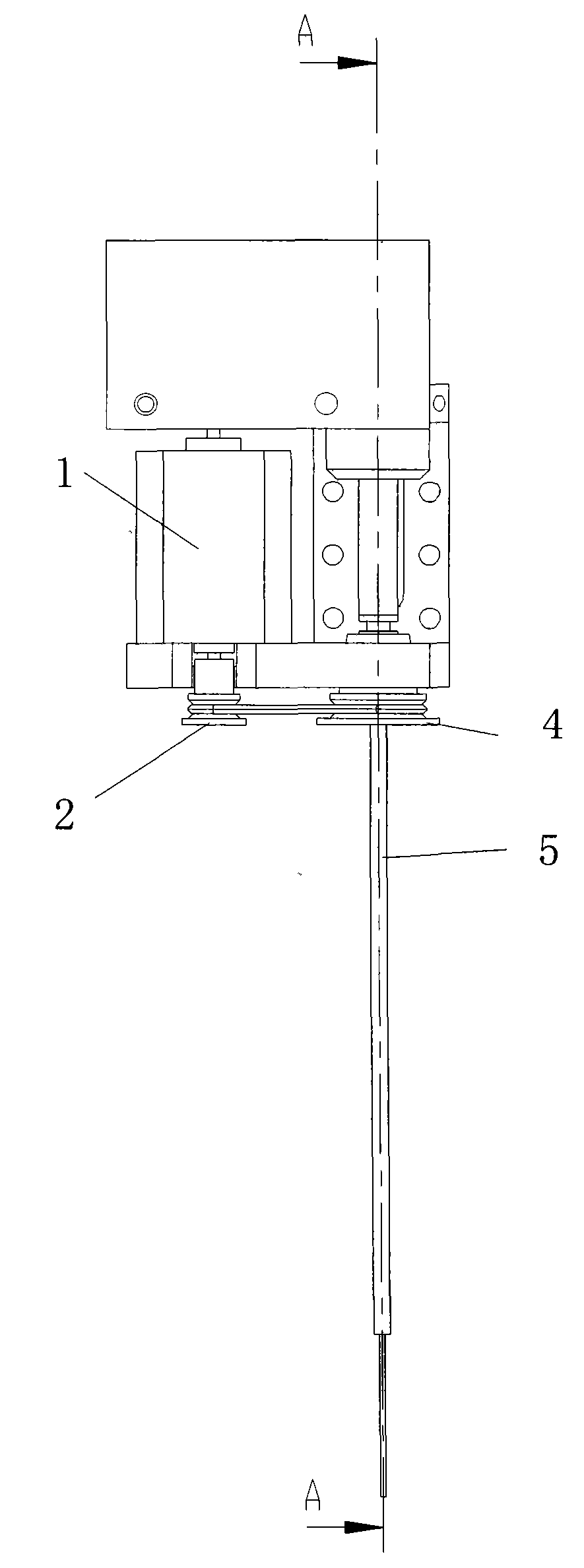

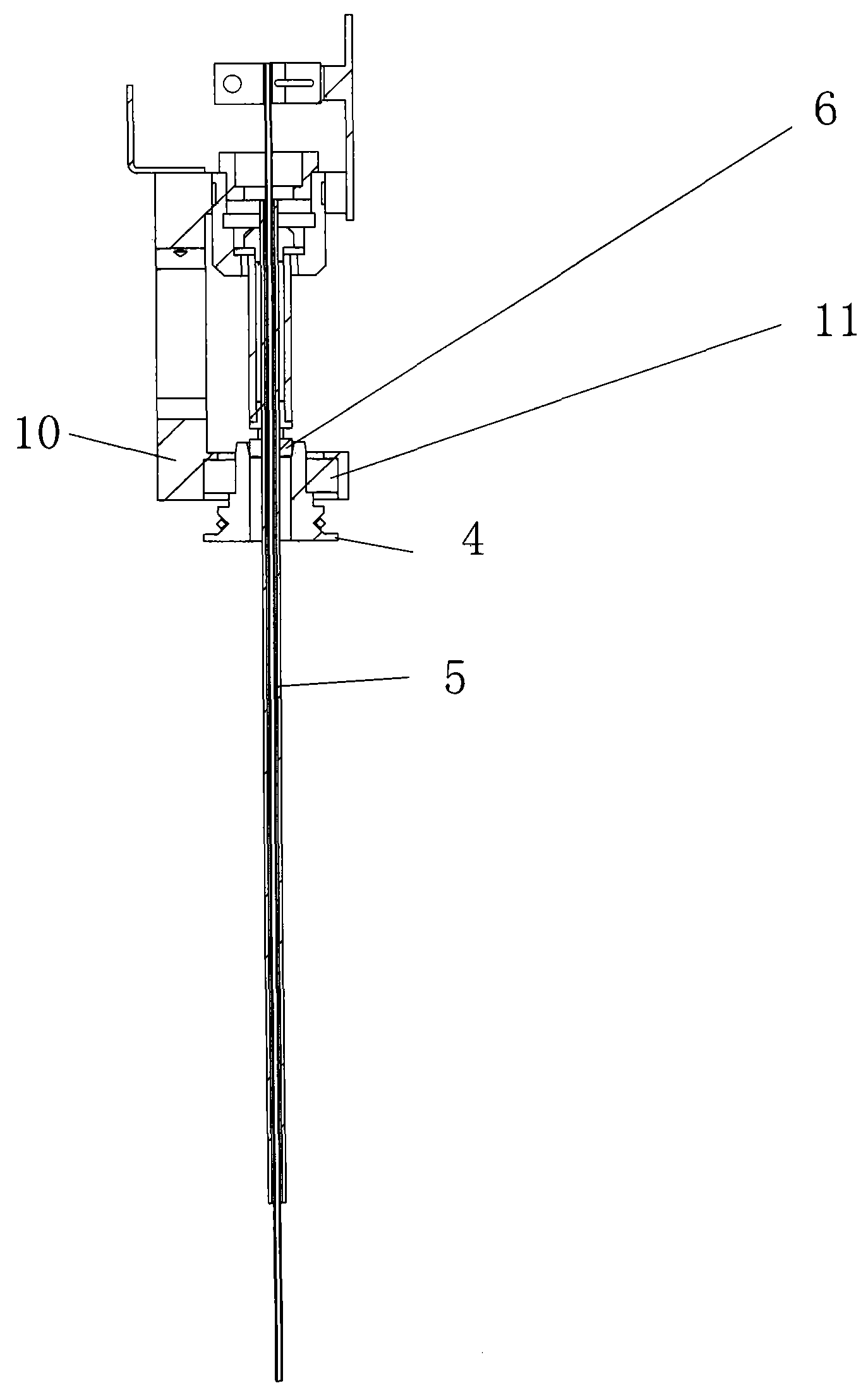

[0026] Such as Figure 1-3 , an integrated sample needle feeding and stirring system, including a fixed seat 10, a stirring motor 1, a driving wheel 2, an eccentric wheel 4 and a sample needle 5; the stirring motor 1 is fixed on the fixed seat 10; the eccentric wheel 4 passes through the first The bearing 11 is installed on the fixed seat 10; the sample needle 5 is installed in the eccentric hole of the eccentric wheel 10 through the second bearing 6; the stirring motor 1 drives the eccentric wheel 4 to rotate through the driving wheel 2.

[0027] Drive wheel 2 is connected with eccentric wheel 4 through belt 3 (or gear) transmission.

[0028] A PCB board 9 with an anti-collision optocoupler 7 is arranged on the fixing seat 10 , and a light blocking sheet 8 is arranged on the top of the sample needle 5 .

[0029] The axis of the eccentric hole deviates from the axis of the eccentric wheel 4 by 0.05-0.2 mm, preferably 0.1 mm. You can also take 0.15mm, 0.13mm, 0.08mm and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com