Adjustable core mold for winding transformer iron core

A technology for transformers and iron cores is applied in the field of adjustable mandrels for winding of transformer cores, which can solve the problems of poor versatility of mandrels and rising production costs, and achieve the effects of strong overall structure, simple design scheme, and high reuse value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

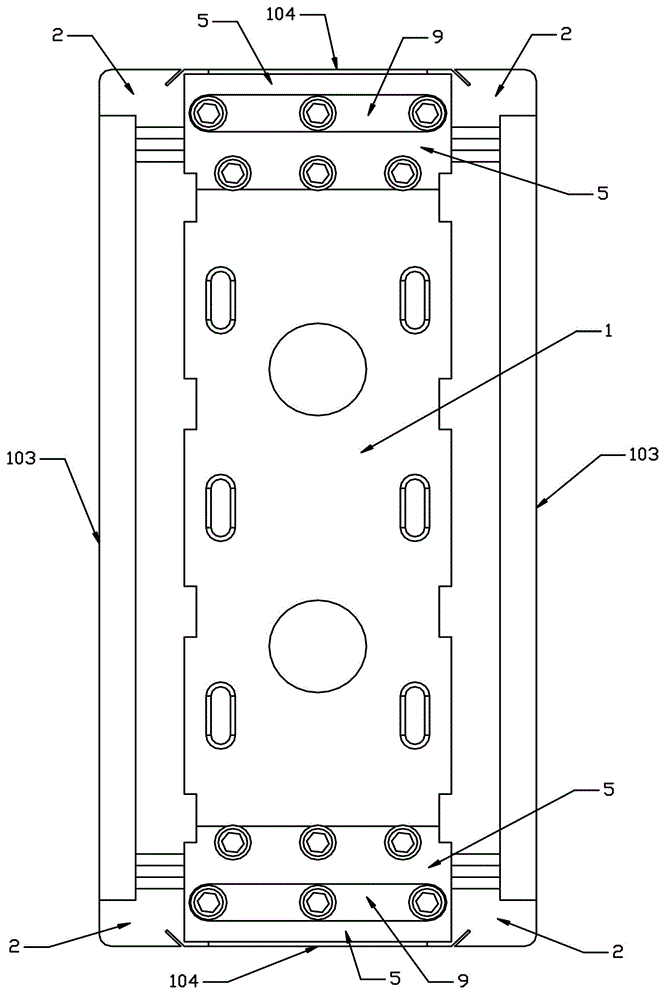

[0023] In this embodiment, the adjustable mandrel for transformer core winding includes a main board 1, four ear plates 2, four connecting middle plates 5, four connecting pieces 9, two side strips 103 and two short side strips 104.

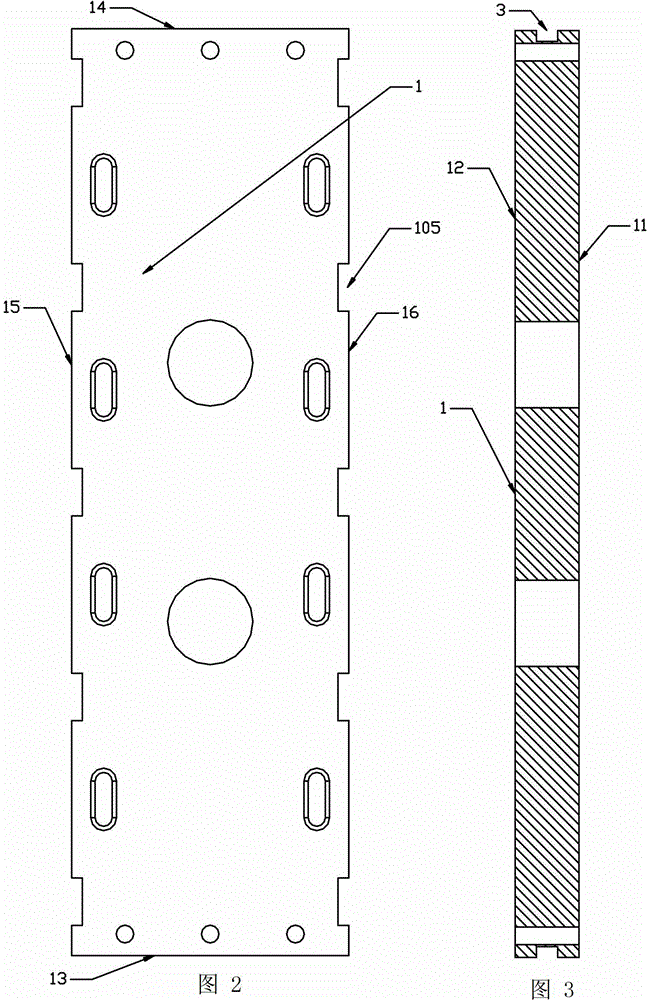

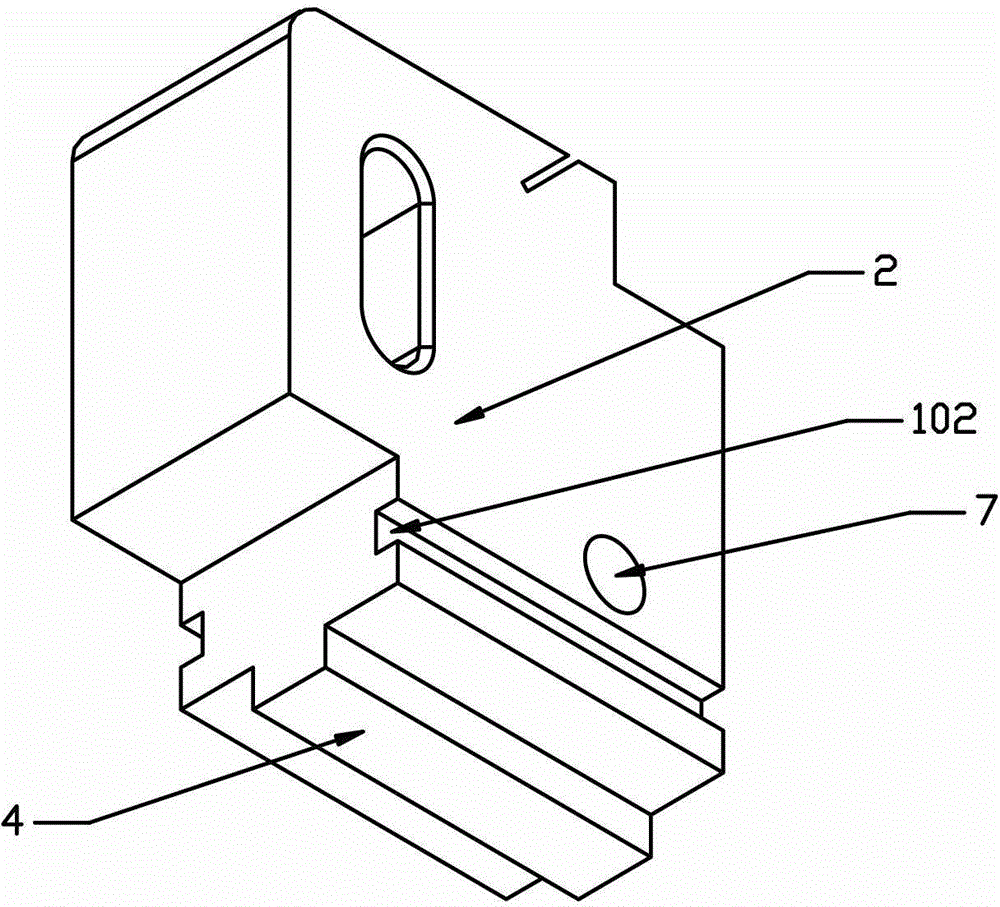

[0024] The main board 1 is provided with a first chute 3, the first chute 3 is arranged along the width direction of the main board 1, and the ear plate 2 is provided with a first The sliding rail 4 , the ear plate 2 can be adjusted in translation relative to the main board 1 along the width direction of the main board 1 . The main board 1 is provided with a through hole, and a groove 105 is provided on the side of the main board 1 in the length direction.

[0025] The main board 1 includes an upper plate surface 11, a lower plate surface 12, a first side 13 along the width direction, a second side 14 along the width direction, a third side 15 along the length direction and a fourth side 16 along the length direction The first sliding groove 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com