How to make a led fluorescent tube

A technology of LED fluorescent lamp and manufacturing method, which is applied in the direction of light source, lampshade, point light source, etc., can solve the problems of high packaging cost and application cost, cumbersome manufacturing process, low light transmittance of lampshade, etc. Material cost, the effect of improving light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the drawings and specific embodiments.

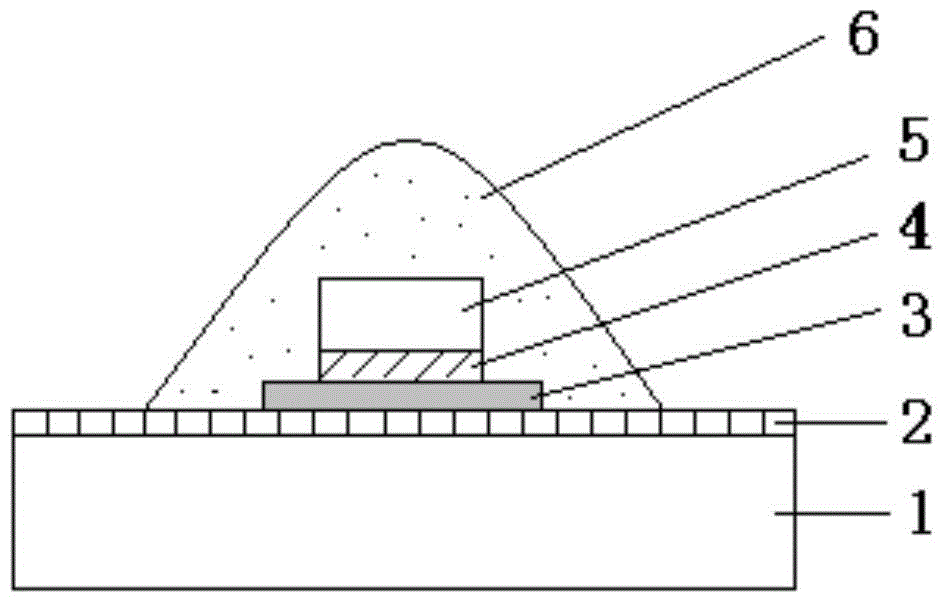

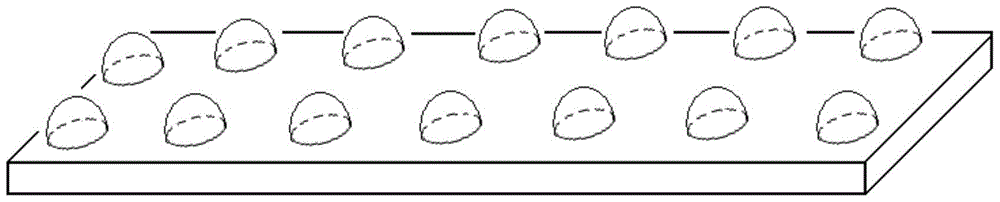

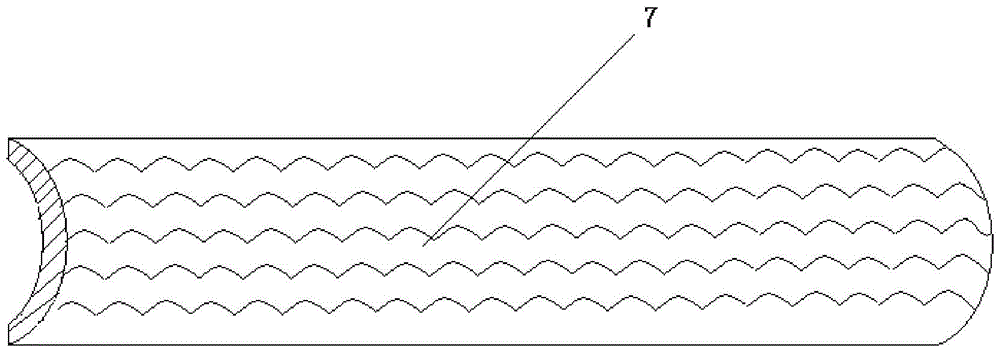

[0041] See figure 1 , The embodiment of the present invention provides a method for manufacturing a new type of fluorescent tube, including the manufacturing of panel LED light sources and the manufacturing of fluorescent tubes.

[0042] First, make a panel LED light source:

[0043] First, use electroplating or sputtering and other chemical methods to plate pure tin or gold-tin alloy on the bottom of the sapphire substrate of the flip chip 5 as the plating layer 4 on the bottom of the flip chip that contacts the aluminum substrate. The flip chip used The power of 5 is 1-3W, and the coating thickness is 0.2-1μm.

[0044] Second, the upper surface of the aluminum substrate 1 is plated with gold or silver as the eutectic layer 2, and the thickness of the eutectic layer is basically equivalent to the thickness of the plating layer on the bottom of the flip chip.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com