Double-work position hydraulic clamping rotating table

A rotary table and hydraulic clamping technology, applied in the field of mechanical processing, to achieve the effect of improving labor productivity, improving work efficiency, and flexible position and angle transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

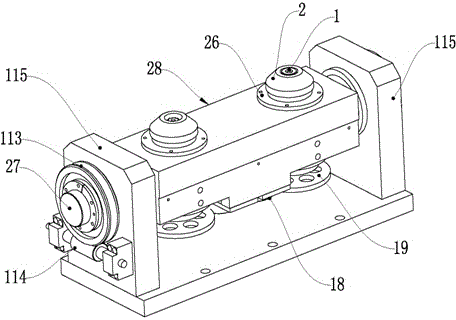

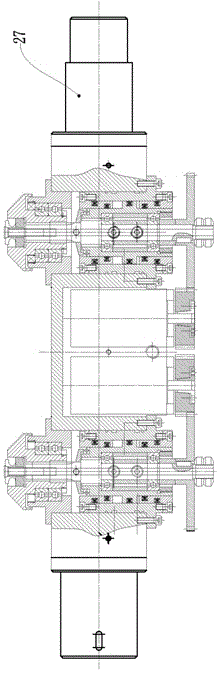

[0023] refer to figure 1 and figure 2 , the dual-station hydraulic clamping rotary table in this embodiment includes a rotary bracket 115, a rotary drive assembly and a rotary body 28; the rotary body 28 is installed on the rotary bracket 115, and is driven by the rotary drive assembly Make a rotary motion; the rotary body 28 includes a rotary shaft 27 and a clamp assembly, and the clamp assembly is at least two sets, both of which are installed on the rotary shaft 27;

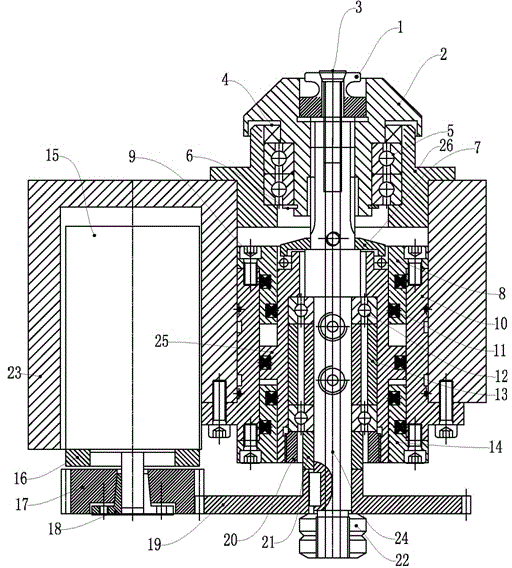

[0024] Such as image 3 , the clamp assembly includes a collet 1, a spline shaft 24, a cylinder piston 25 and a rotary motor 15; the rotary motor 15 drives the spline shaft 24 to rotate, and the cylinder piston 25 is arranged in the cylinder and is hydraulically Oil drive can move linearly, and described spline shaft 24 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com