Method for solving problem of die locking force change in production process of injection molding machine

A production process and solution technology, which is applied in the field of solving the problem of mold clamping force changes during the production process of injection molding machines, can solve problems such as mold clamping force changes, and achieve the effect of achieving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

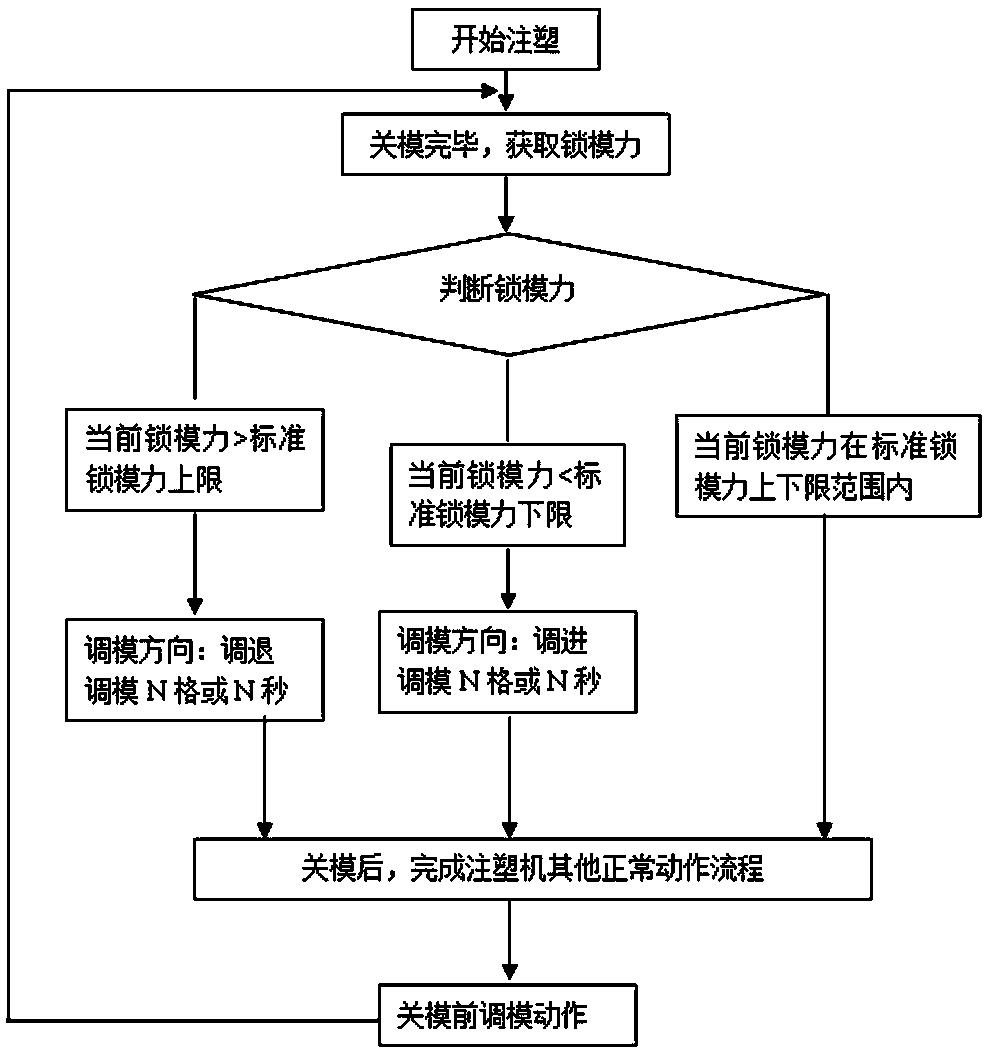

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention installs a hydraulic pressure sensor at the system oil pressure or the mold closing oil cylinder on the injection molding machine, and the hydraulic pressure sensor is connected with the control system; the solution comprises the following steps:

[0016] 1): The injection molding machine starts injection molding and closes the mold. The clamping force is detected by the hydraulic pressure sensor, and the standard clamping force in the production process is automatically generated through the control system;

[0017] 2): After the mold clamping is completed, the control system judges whether to adjust the mold according to the detected current clamping force. If the mold adjustment action is required, the mold adjustment direction is judged according to the clamping force; it is judged that the current clamping force exceeds the stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com