Multifunctional automatic stamping machine and using method thereof

A stamp machine and multi-functional technology, applied in printing, stamping, etc., can solve the problems of different applied force, troublesome seal management, difficult to distinguish between authenticity and falsehood, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

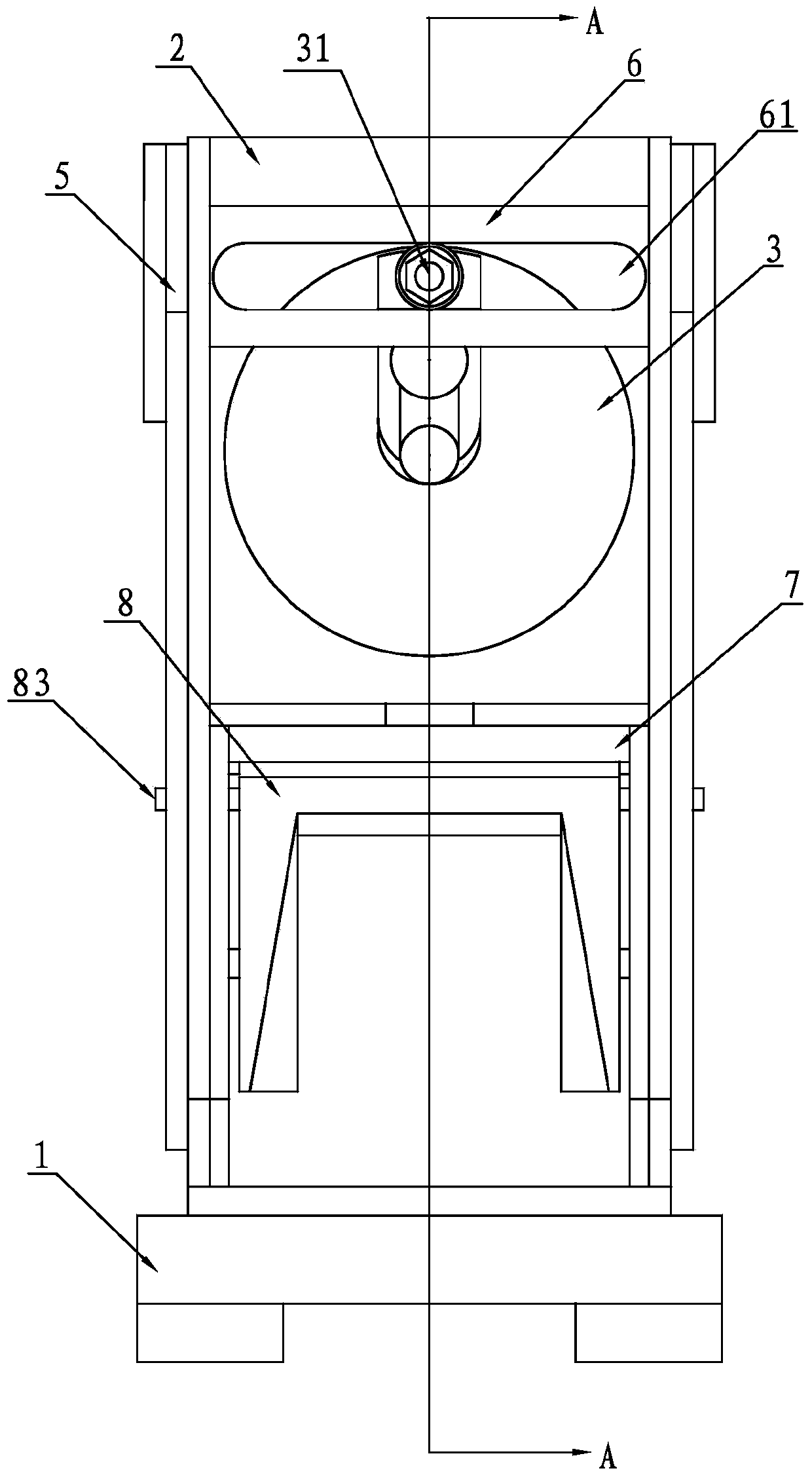

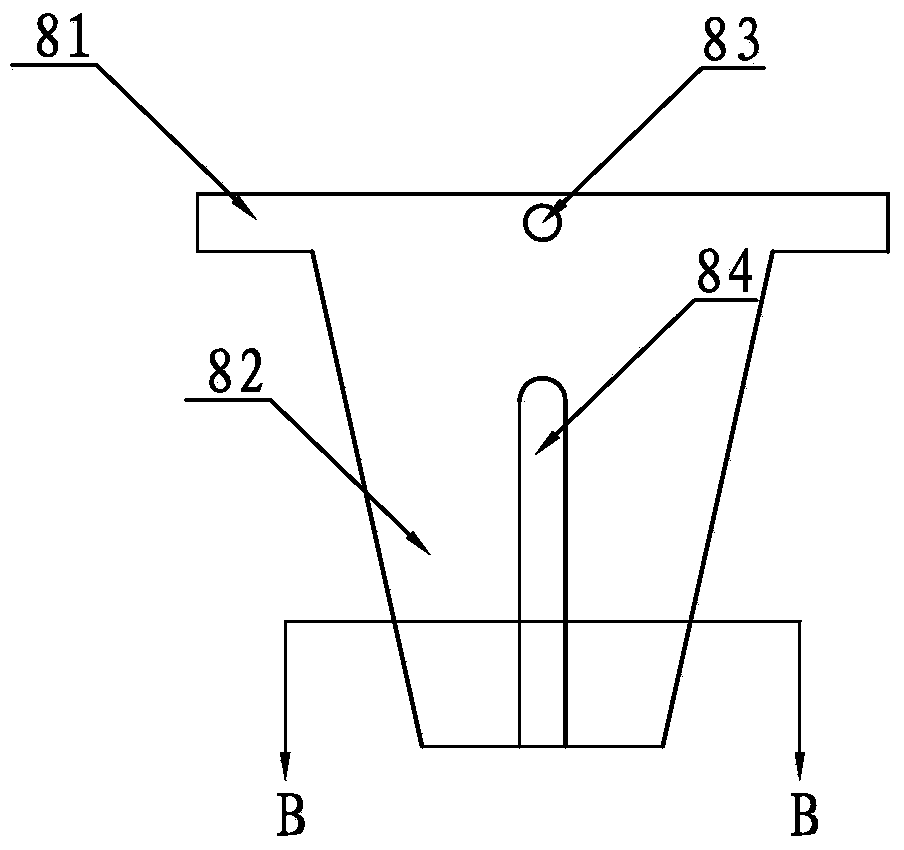

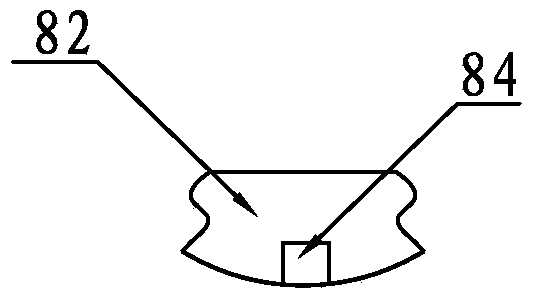

[0029] Embodiment 1: a kind of multifunctional automatic seal machine, as Figure 1-11 Shown: including frame 1, frame 2, eccentric wheel 3, motor 4, vertical sliding part 5, sliding bar 6, ink pad box 7 and stamp part 8, the frame 2 is arranged on the frame 1, the The machine base 1 includes a horizontal base plate 11 and a vertical seat plate 12, the vertical base plate 12 is arranged on the left side of the horizontal base plate 11, and the frame 2 includes a side plate 21, a vertical plate 22, an ink pad baffle plate 23, and a flip vertical plate 24 and toggle shaft 25, two side plates 21 are respectively fixed on the left and right sides of the vertical seat plate 12 of the machine base 1, a paper feeding gap is provided between the bottom edge of the two side plates 21 and the horizontal bottom plate 11, and the vertical plate 22 is vertically arranged between the two side plates 21, and is located in the middle of the side plates 21, the motor 4 is installed on the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com