Test-tube stand for batch inoculation in laboratory

A laboratory and test tube rack technology, applied in the field of test tube racks for batch inoculation in the laboratory, can solve the problems of long exposure time, damage to experimental materials, and easy overturning of alcohol lamps, etc., to achieve convenient operation, safety protection, and avoid personal injury damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

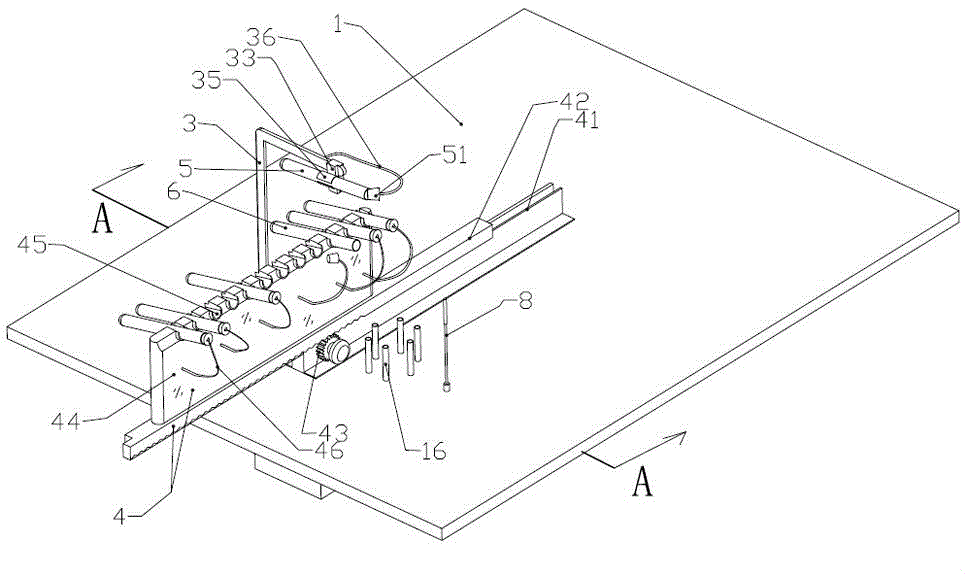

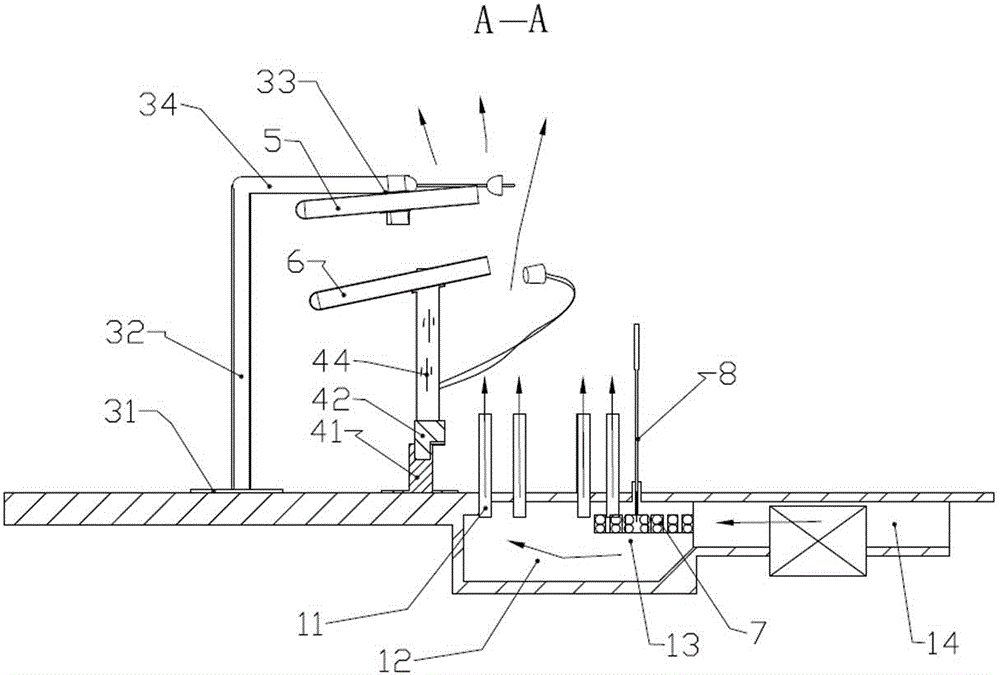

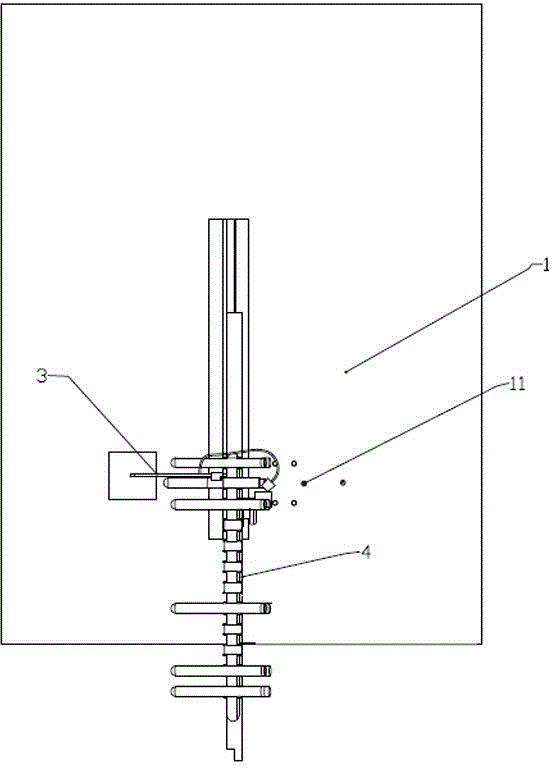

[0033] Such as Figure 1 to Figure 6 as shown,

[0034] A test tube rack for batch inoculation in a laboratory, the test tube rack is a whole, including a base 1, the base 1 is a stainless steel plate, and can be placed on an ultra-clean workbench.

[0035] The base 1 is fixed with a strain parent tube fixing bracket 3 and a test tube mounting bracket 4 to be inoculated, the strain parent tube fixing bracket is used for fixing the strain parent tube, and the test tube mounting bracket to be inoculated is used for inoculating the test tube to be inoculated. A cavity is provided on the rear side of the base for installing components such as a control circuit board.

[0036] The strain mother tube fixing bracket 3 includes a fixed plate 31, a column 32 and a test tube clamp 33, the fixed plate 31 is fixed on the base by screws, the column 32 extends upwards and forms a space to avoid the test tubes to be inoculated on the lower side, and the column is inverted as a whole L shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com