Power equipment base fastening device and fixing method

A technology for power equipment and fastening devices, applied in infrastructure engineering, construction, etc., can solve problems such as installation difficulties, loose fasteners, and the existence of dangerous factors, and achieve the effect of convenient construction and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

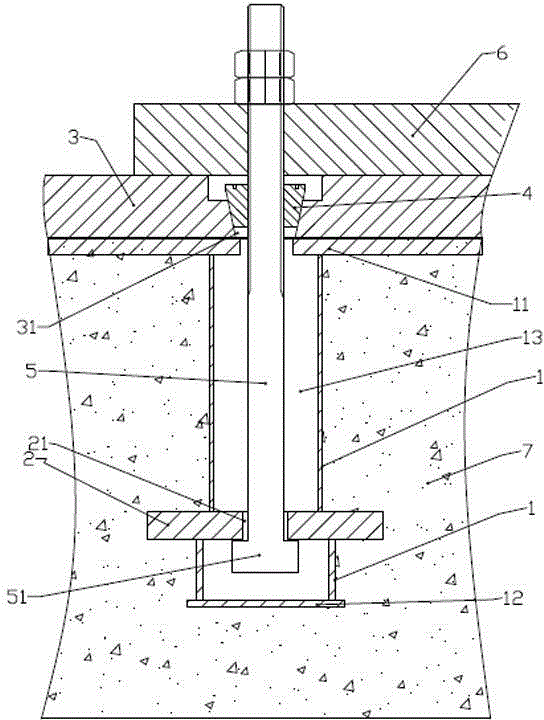

[0036] Such as Figure 1 to Figure 8 as shown,

[0037] A power equipment base fastening device includes the following parts.

[0038] -Concrete foundation 7 by pouring and solidification molding, this is foundation work.

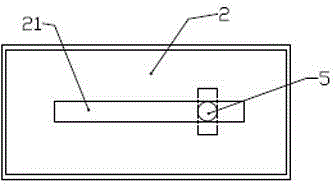

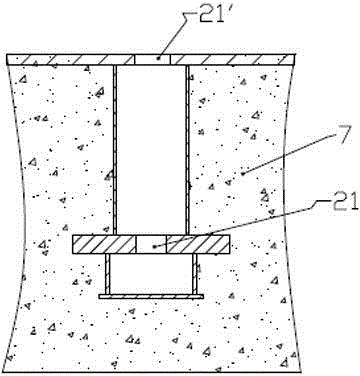

[0039] Make a cuboid box body 1, which is formed by welding thick steel plates. The top plate 11 and the bottom plate 12 are extended to both sides. The extension design has two purposes, one is to increase the bonding force with the concrete foundation, and the other is to provide the following The welding between the steel backing plates provides convenience. The middle and lower part of the box cavity 13 is provided with a horizontal anchor plate 2, and the anchor plate 2 is welded into one body with the box body and the two sides of the anchor plate extend to the concrete foundation outside the box body. Open a long hole 21 on the top, as figure 2 As shown; the anchor plate 2 is the main part bearing the tension of the bolt, and it adopts a thicker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com