Cement foam insulation cover board on the outer layer of the building wall

A technology for building walls and cement foaming, which is used in buildings, building components, building structures, etc., can solve the problems of hidden dangers in management and maintenance, large temperature difference between day and night, and falling off of insulation blocks, and achieves long service life and good flame retardant effect. , fixed and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

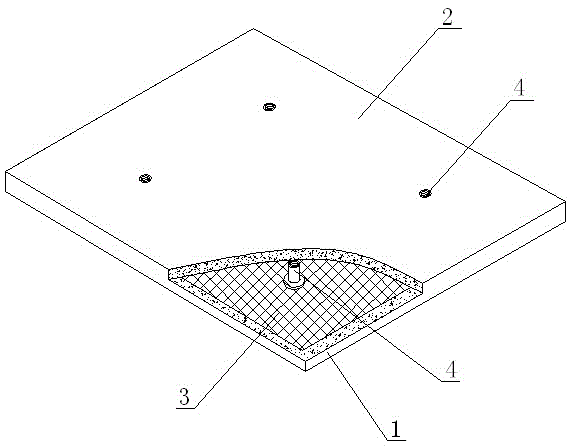

[0013] Such as figure 1 As shown, the cement foam insulation cover board of the outer layer of the building wall of the present invention is composed of the surface layer 1 and the lining layer 2, and the reinforcement mesh 3 is solidified between the surface layer 1 and the lining layer 2, and the lining layer The surface of 2 is planted with connecting stake 4.

Embodiment 2

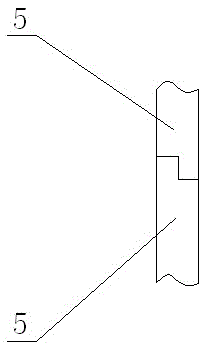

[0015] Such as figure 1 As shown, the cement foam insulation cover board of the outer layer of the building wall of the present invention is composed of the surface layer 1 and the lining layer 2, and the reinforcement mesh 3 is solidified between the surface layer 1 and the lining layer 2, and the lining layer 4 connection piles 4 are planted on the surface of 2. The connecting pile 4 penetrates the lining layer 2, and its root is solidified with the reinforcement net 3 to form a whole. The edge of the cover plate is an L-shaped interface, and the L-shaped edge interfaces spliced one by one are lap joints (such as figure 2 ).

Embodiment 3

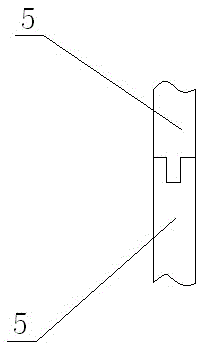

[0017] The cement foam insulation cover board of the outer layer of the building wall of the present invention is composed of a surface layer 1 and a lining layer 2, and a reinforcement mesh 3 is solidified between the surface layer 1 and the lining layer 2, and on the surface of the lining layer 2 There are 6 connecting piles 4 planted on the top. The connecting piles 4 penetrate the lining 2, and their roots are solidified with the reinforcement mesh 3. The connecting piles 4 are internally threaded nuts, and the whole is vertically embedded in the lining. 2 in. The edges of the cover plate are respectively convex and concave, and the convex and concave edge interfaces that are spliced with each other one by one are socket interfaces (such as image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com