A triangular circular arc convex rib friction welding drill pipe and its welding method

A friction welding and friction welding technology, applied in drill pipes, welding equipment, drill pipes, etc., can solve the problems of difficulty in guaranteeing welding quality, inability to continuously contact, and many production processes, so as to improve welding quality, reduce thermal deformation, and improve welding quality. The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further explained and illustrated through specific embodiments below in conjunction with the accompanying drawings.

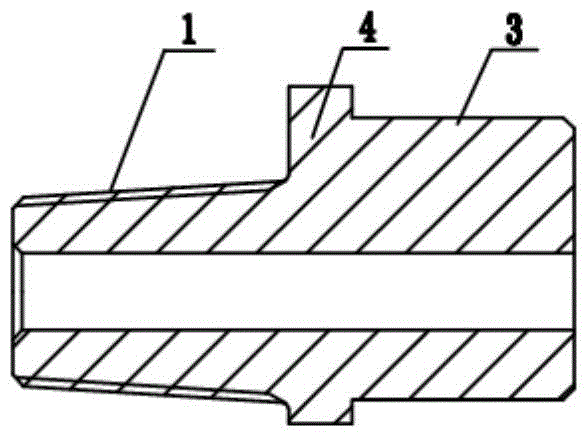

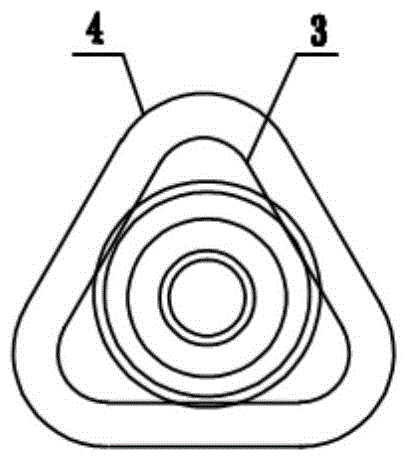

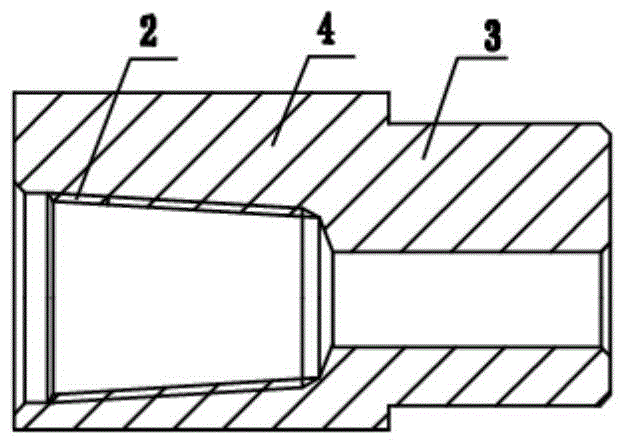

[0029] Such as Figure 1-5 as shown, Figure 1-2 It is the original externally threaded joint, which includes the externally threaded connection part 1 and the welding part; Figure 3-4 It is the original internal thread connector, which includes the internal thread connection part 2 and the welding part, wherein the welding part adopts a stepped prism, that is, it is composed of a step end 4 with a large triangular cross section and a small triangular stepped end 3 with a small triangular cross section, and the large triangular The step is consistent with the shape of the original triangular arc convex rib drill pipe 5, and the small triangular step end is consistent with the inner triangle of the triangular arc convex rib drill pipe. When connecting, the small triangular step end is inserted into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com