Double-axis multi-force cylinder

A technology of multiple force and cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problems of increased machining accuracy requirements, easy deformation of the piston rod, unreasonable structural settings, etc., to achieve strong anti-bending and anti-torsion performance, not easy to deform or broken, easy to fine-tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

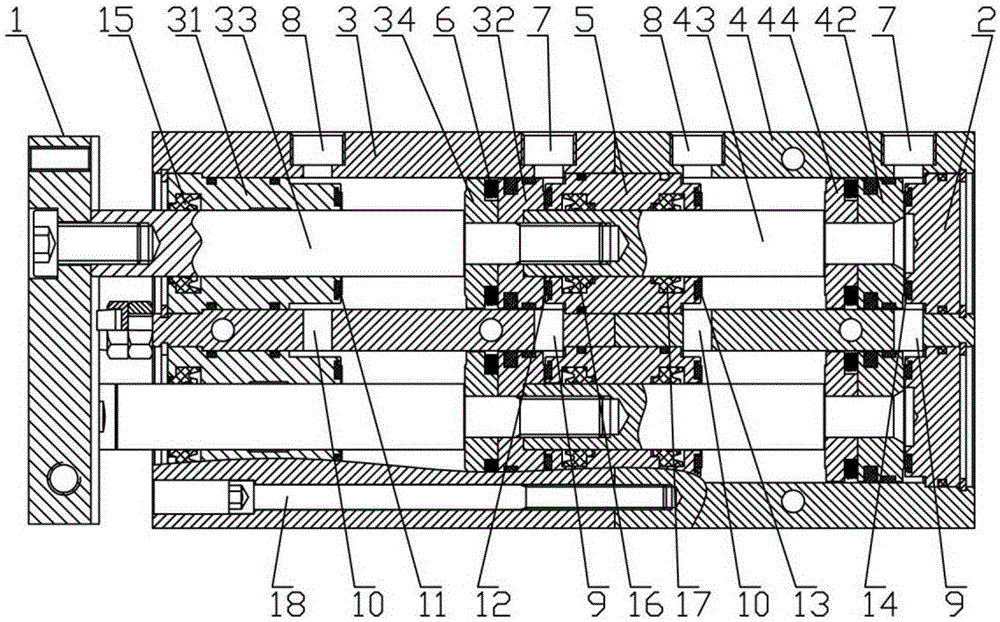

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 The shown biaxial multi-force cylinder includes a front end cover 1, a rear end cover 2, a first cylinder body 3, and a second cylinder body 4 that is mated and connected with the first cylinder body 3, and the second cylinder body 4 is installed Located on the rear end cover 2, the first cylinder body 3 and the second cylinder body 4 cooperate in the axial direction to form two side-by-side inner chambers, and the first air chamber unit and the second air chamber unit are respectively arranged in the two inner chambers. Two air chamber units, a connection seat 5 is provided between the first air chamber unit and the second air chamber unit, and the connection seat 5 is sealed and installed at the joint of the first cylinder body 3 and the second cylinder body 4 .

[0015] The first air chamber unit includes a guide seat 31 sealed in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com