Polar cold-resistant flexible cable and its manufacturing process

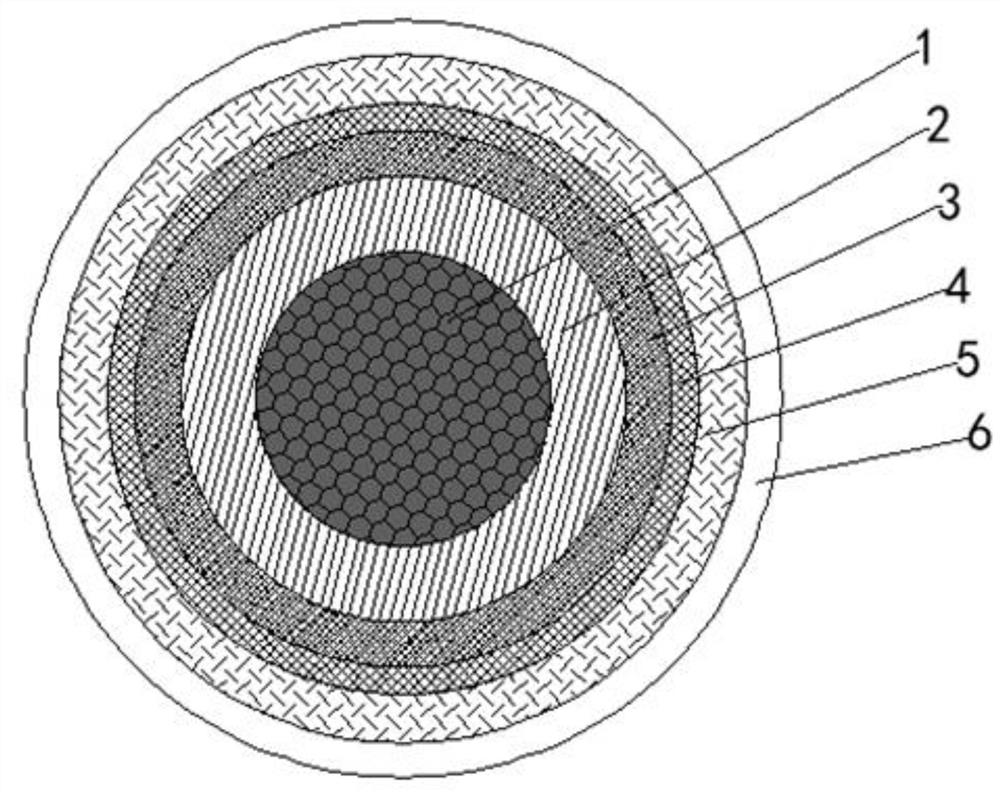

A flexible cable and cold-resistant technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, and cables with twisted pairs/quadrates, etc. It can solve the problems of single function, large size of winch equipment, and large outer diameter of cables, etc. problems, to achieve the effect of speeding up the sampling progress, improving reliability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] The present embodiment provides a polar cold-resistant flexible cable, which is prepared according to a manufacturing process comprising the following steps:

[0092] (1) Production of inner conductor:

[0093] 1.1) Production of silver-plated copper monofilament: After the hard copper rod is drawn into a copper monofilament with a specified wire diameter through a copper wire drawing machine, the drawn copper monofilament is continuously annealed under the protection of water vapor. The nominal outer diameter of the monofilament is 0.22mm, and at the same time, a silver layer with a thickness of not less than 2 μm is plated on the surface of the copper layer of the obtained monofilament to obtain a silver-plated copper monofilament of 0.22mm, and its electrical conductivity is better than GB / T 3953-2009 China's requirements for TR type soft round copper wire, and have excellent weather resistance;

[0094] 1.2) Production of copper-magnesium alloy wire: The copper-mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com