Actuator for mechanical automatic transmission clutch

A technology for automatic transmissions and actuators, applied to mechanical equipment, mechanical energy control, electric components, etc., can solve the problems of large occupied volume of the overall mechanism, increased production cycle and cost, and long clutch separation time, so as to shorten the separation time and reduce the Requirements, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

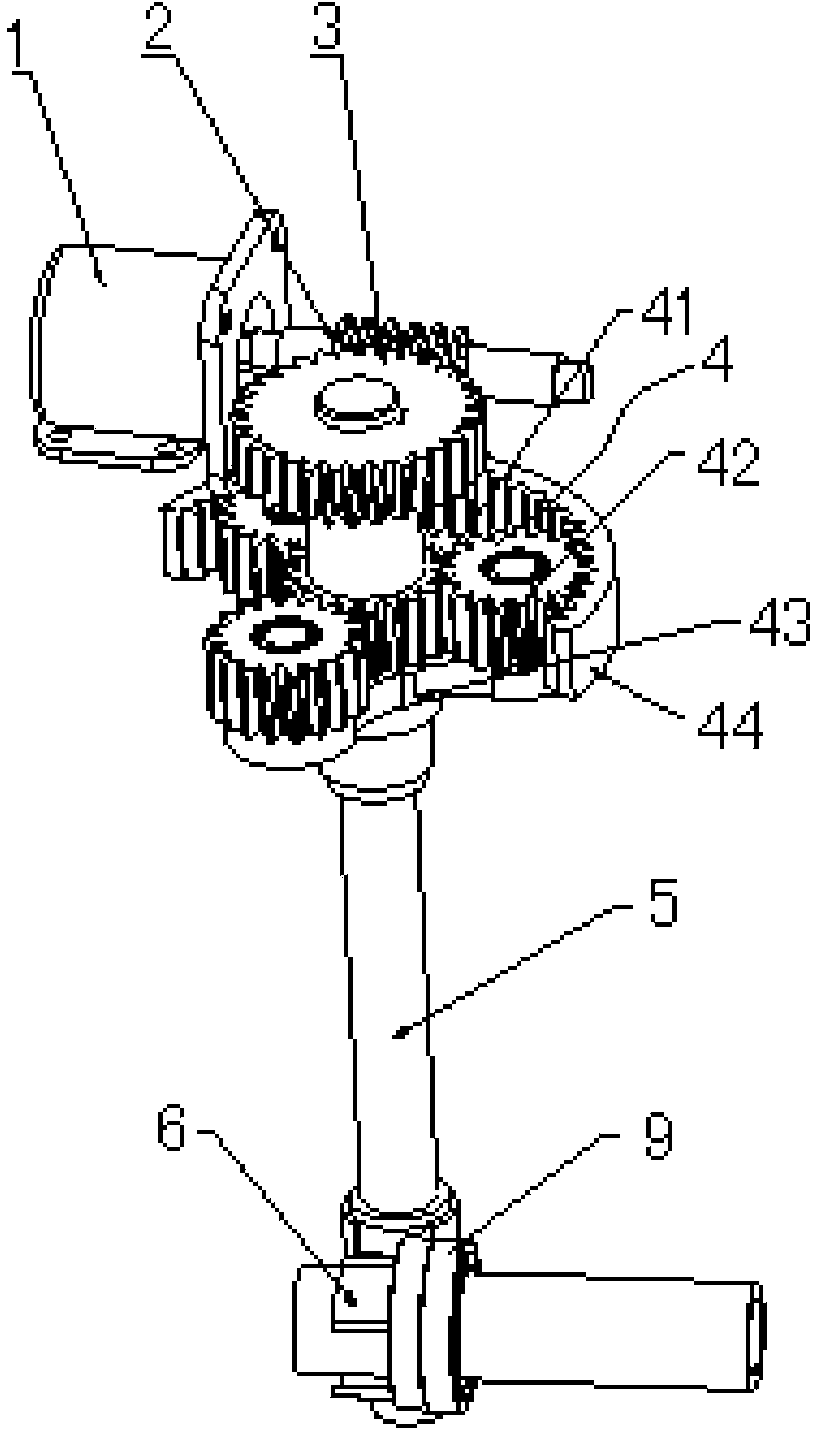

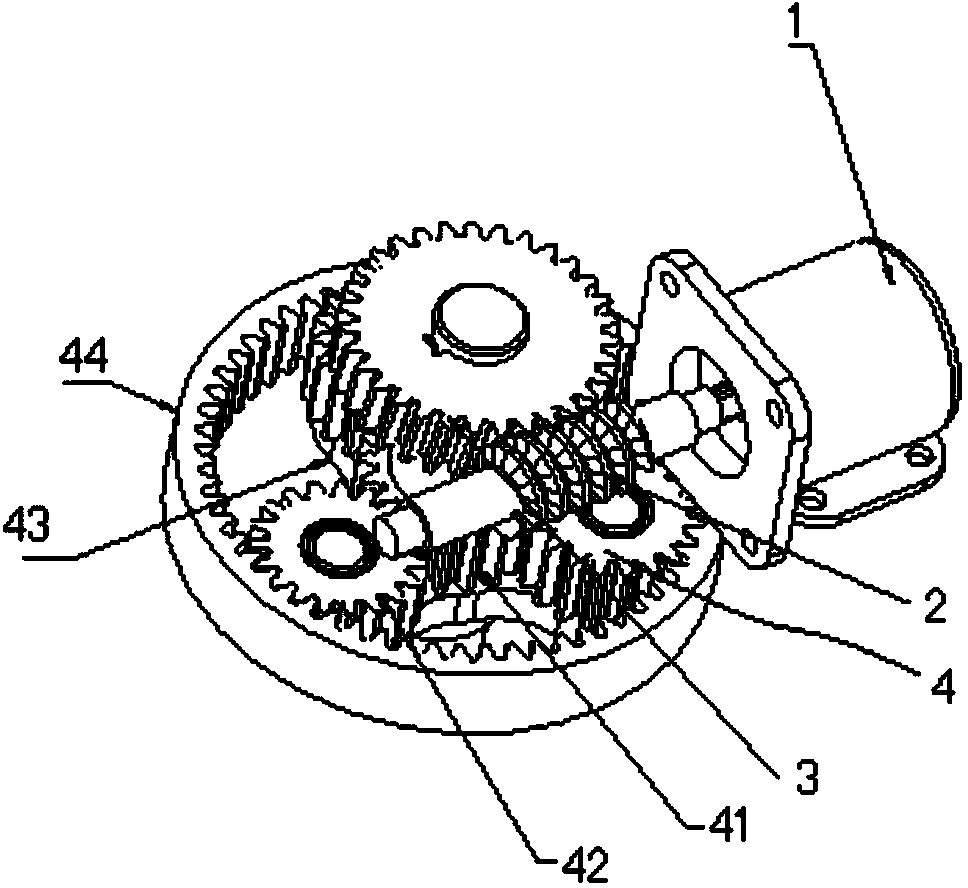

[0012] Such as figure 1 , figure 2 As shown, the present invention includes a clutch motor 1 , the output shaft of the clutch motor 1 is fastened to a worm 2 , the worm 2 meshes with a worm wheel 3 , and the worm wheel 3 is connected to a planetary gear train 4 . The planetary gear train 4 includes a sun gear 41, two or more planet gears 42 meshing around the sun gear 41, a planet carrier 43 tightly connected with each planet gear and a tooth meshing on the outside of each planet gear 42. Circle 44. The worm gear 3 is coaxially fastened to the sun gear 41 , the planet carrier 43 is fastened to a shift fork shaft 5 , and the shift fork shaft 5 is fastened to a clutch shift fork 6 .

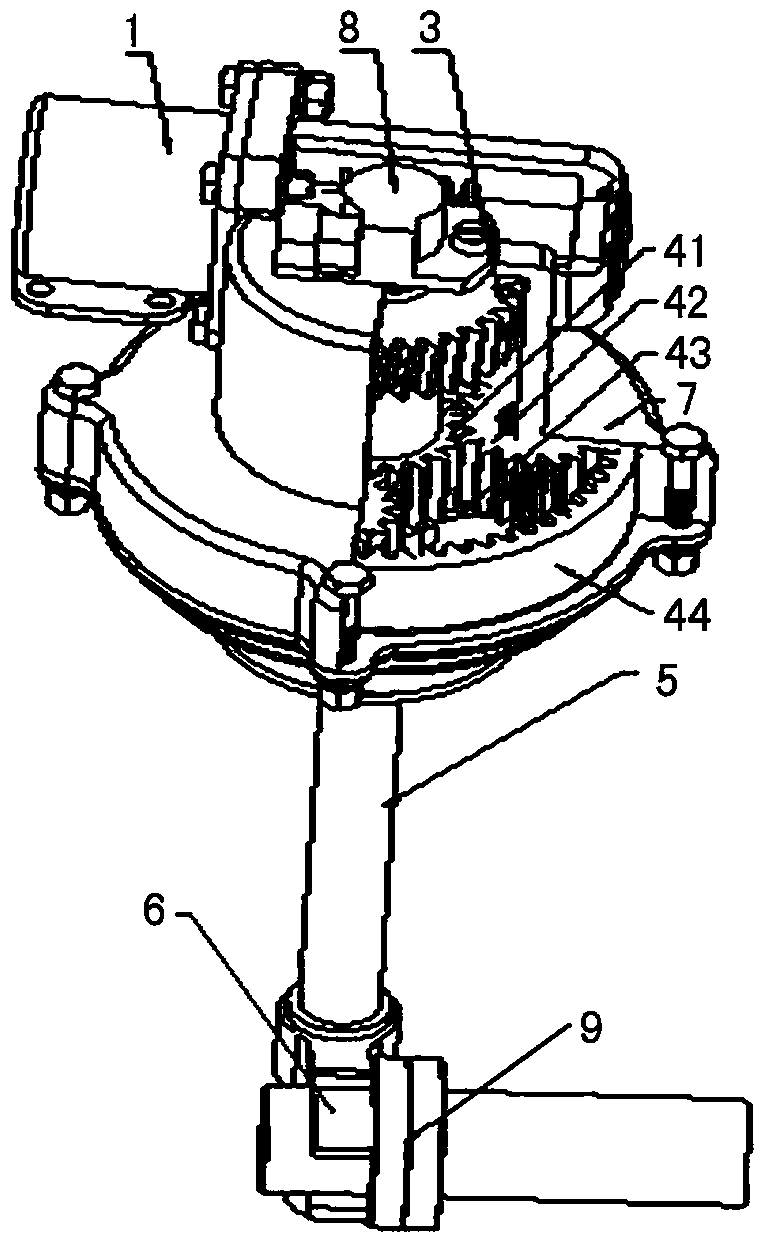

[0013] In the above embodiment, if image 3 As shown, the present invention can also include a housing 7, the output end of the clutch motor 1, the worm 2, the worm g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com