Automatic non-contact hydro-generator rotor roundness measuring device and method

A hydro-generator and automatic measurement technology, which is applied to electromagnetic measurement devices, electric/magnetic profile/curvature measurement, etc., can solve the problems of heavy manual calculation and analysis workload, low precision when measuring roundness by dial indicator, etc. Achieve the effect of automatic recording, reducing manual workload and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

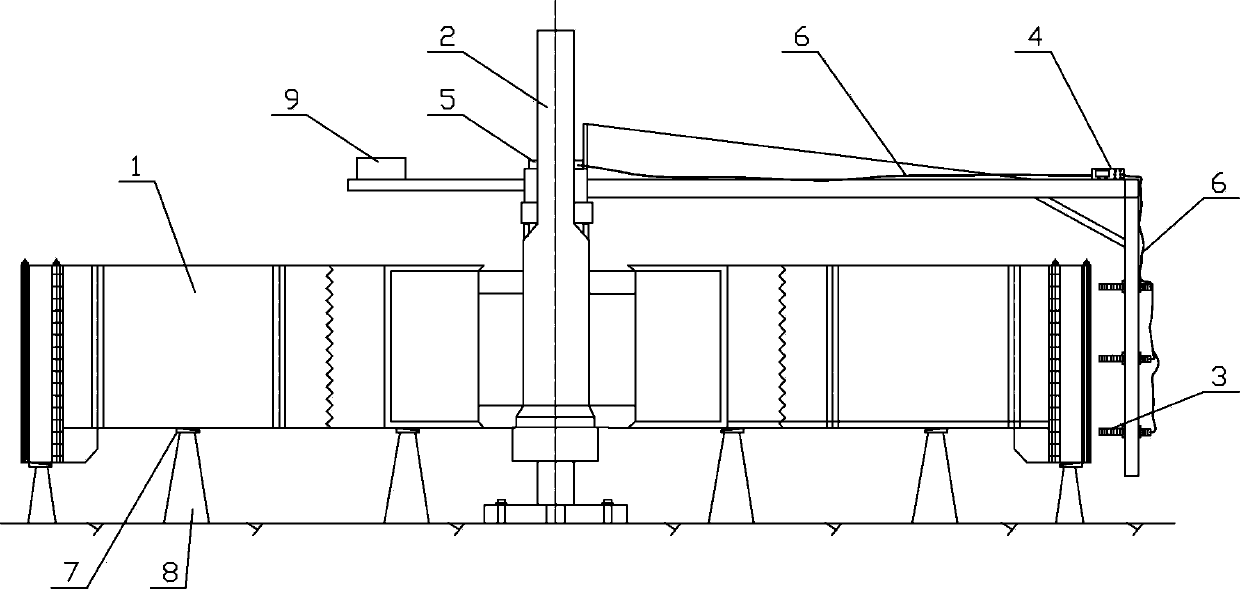

[0025] Such as figure 1 Among them, a non-contact automatic measuring device for the roundness of the rotor of a hydro-generator comprises a round measuring frame 2, the end of the round measuring frame 2 is provided with a vertical measuring arm 10 which rotates along the outer wall of the rotor 1, and the vertical measuring arm 10 is provided with a plurality of eddy current sensors 3 from top to bottom, and the eddy current sensors 3 are not in contact with the rotor 1, and a gear disc counter 5 is arranged on the rotating shaft of the round measuring frame 2, and the eddy current sensors 3 and the gear disc counter 5 pass through the wire The cable 6 is connected with the data collector 4 . In this example, the data collector 4 is arranged on the measuring circle frame 2, and the data collector 4 is connected with a computer. The eddy current sensor can measure the distance between the metal conductor under test and the surface of the probe with non-contact, high linearit...

Embodiment 2

[0030] On the basis of Embodiment 1, a method for automatically measuring the roundness of the rotor of a hydroelectric generator using the above-mentioned device comprises the following steps:

[0031] 1. Level the rotor 1, install the round frame 2, install the eddy current sensor 3, the disc counter 5 and the data collector 4; install the round frame 2 at the center of the rotor 1 to be tested to ensure the installation accuracy of the round frame .

[0032] According to the mathematical model of the rotor 1 to be measured, determine the measurement parameters of the elevation, angle, and radial gap value of the point to be measured, and write a special program for processing data.

[0033] 2. Rotate the round frame, the eddy current sensor 3 measures the roundness of the rotor 1 to be tested, and each magnetic pole should be set with a measuring point; each measuring point needs to record the elevation of the point to be measured, the angle of rotation, and the gap value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com