Optical axis calibration gauge, system and method

A calibration method and optical axis technology, applied in the direction of testing optical performance, etc., can solve the problems of complex structure and high cost of optical axis calibration fixture, and achieve the effect of convenient optical axis calibration method, simple structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

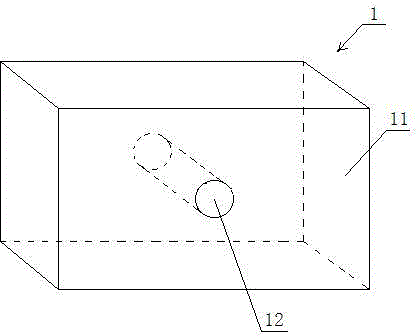

[0040] Embodiment 1, this embodiment provides an optical axis calibration jig, see figure 2 As shown, the optical axis calibration jig 1 includes a body 11. In order to clearly introduce the working principle of the present invention, in this embodiment, the body 11 is provided with a circular through hole 12, and the through hole 12 is two ends Straight holes parallel to each other, see image 3 shown, the via length , where h is the length of one pixel of the calibration camera, It is the maximum deviation angle value of the fixture. By accurately calculating and limiting the length of the through hole, the optical axis calibration jig can not only limit the deviation within the required accuracy range, meet the calibration accuracy requirements, but also make the calibration accuracy of the optical axis calibration jig not too large ( The larger the L, The smaller the value, the higher the corresponding accuracy), which is beneficial to reduce the amount of calculat...

Embodiment 2

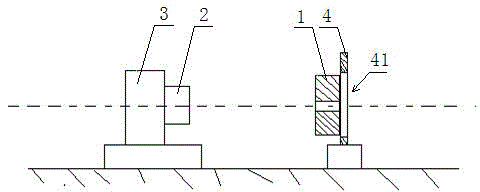

[0045] Embodiment 2, based on the optical axis calibration system in Embodiment 1, this embodiment provides an optical axis calibration method, including the following steps:

[0046] (1) Make the optical axis calibration jig, please refer to the attached drawings Figure 2-Figure 4 shown, including: Computing the length value , where h is the length of one pixel of a calibration camera, In order to calibrate the maximum deviation angle value of the fixture; according to the length value L, the optical axis calibration fixture 1 is made, and the optical axis calibration fixture 1 includes a body 11, and a circular or polygonal through hole 12 is opened on the body, and the through hole is A straight hole with two ends parallel to each other, and the length of the through hole is L;

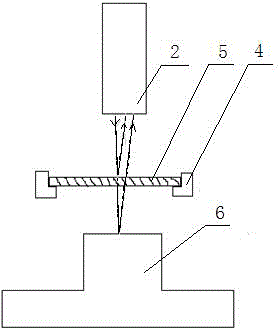

[0047] (2) Fix the optical axis calibration jig 1 on a carrying platform 4, the carrying platform 4 has a light transmission hole 41, the light transmission hole 41 is connected with the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com