System and method for testing high-frequency fatigue life in high-temperature steam environment

A high-temperature steam and fatigue life technology, applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., can solve the problem of not being able to meet the high-temperature steam environment, and achieve the effect of easy guarantee of test accuracy, simple operation and good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]The specific implementation of the high-frequency fatigue life test system and test method in the high-temperature steam environment of the present invention will be described in detail below in conjunction with the accompanying drawings. The implementation object of this example is the steam turbine blade material Ti-6Al-4V, its service environment is steam at 100oC, and the dissolved oxygen content is required to be less than 0.8ppm.

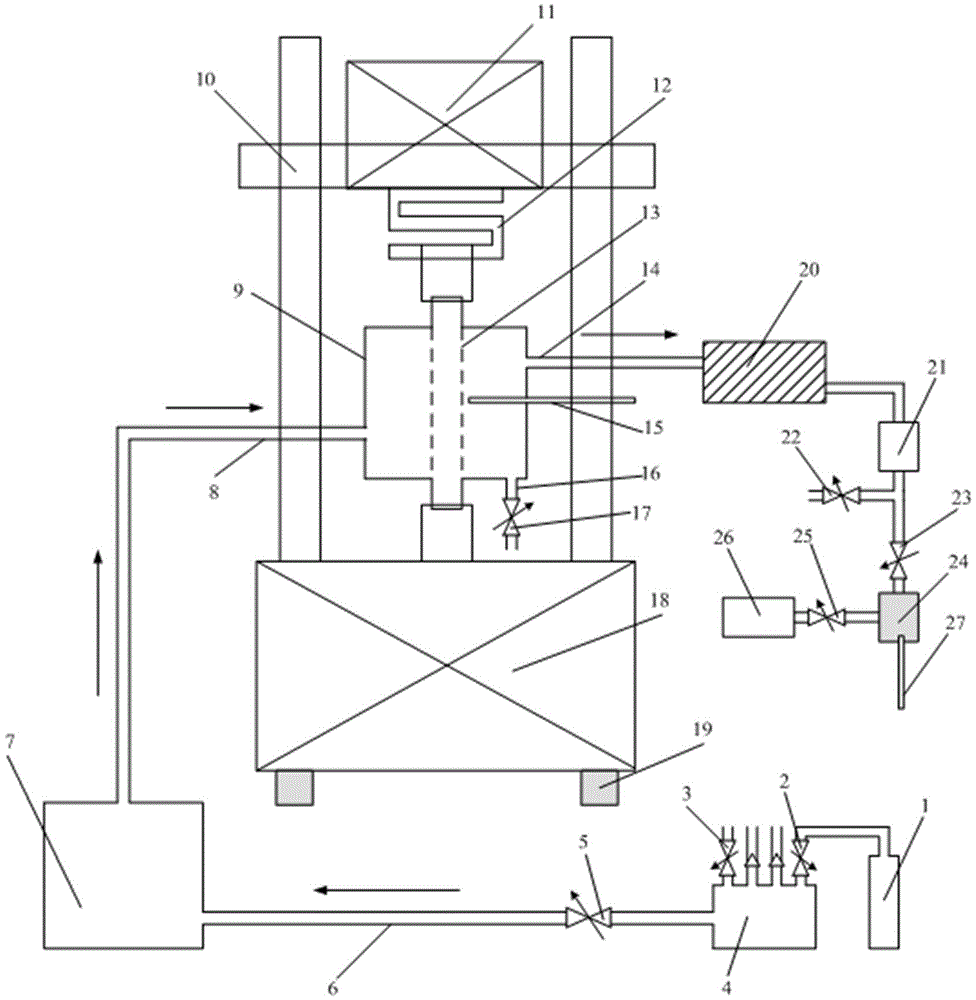

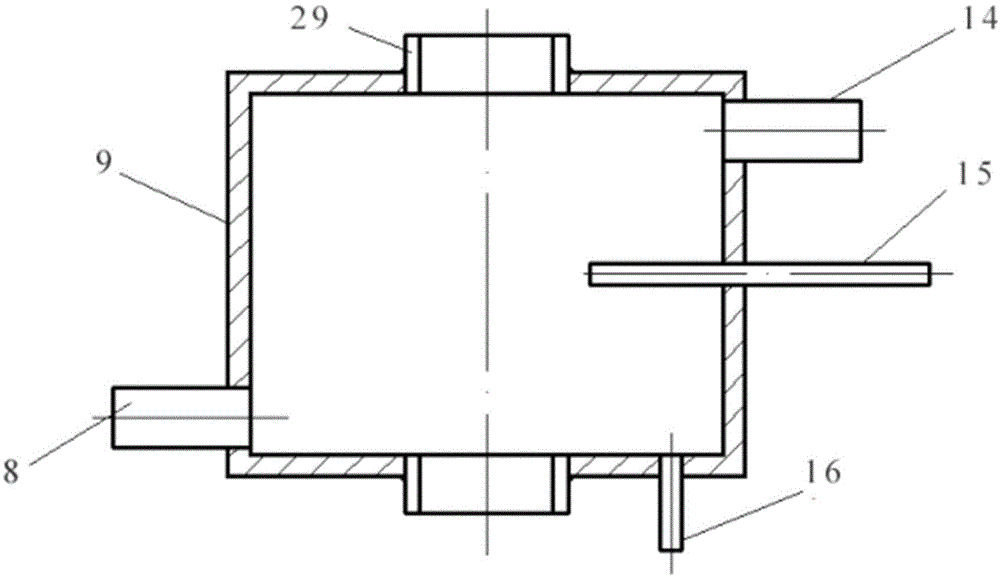

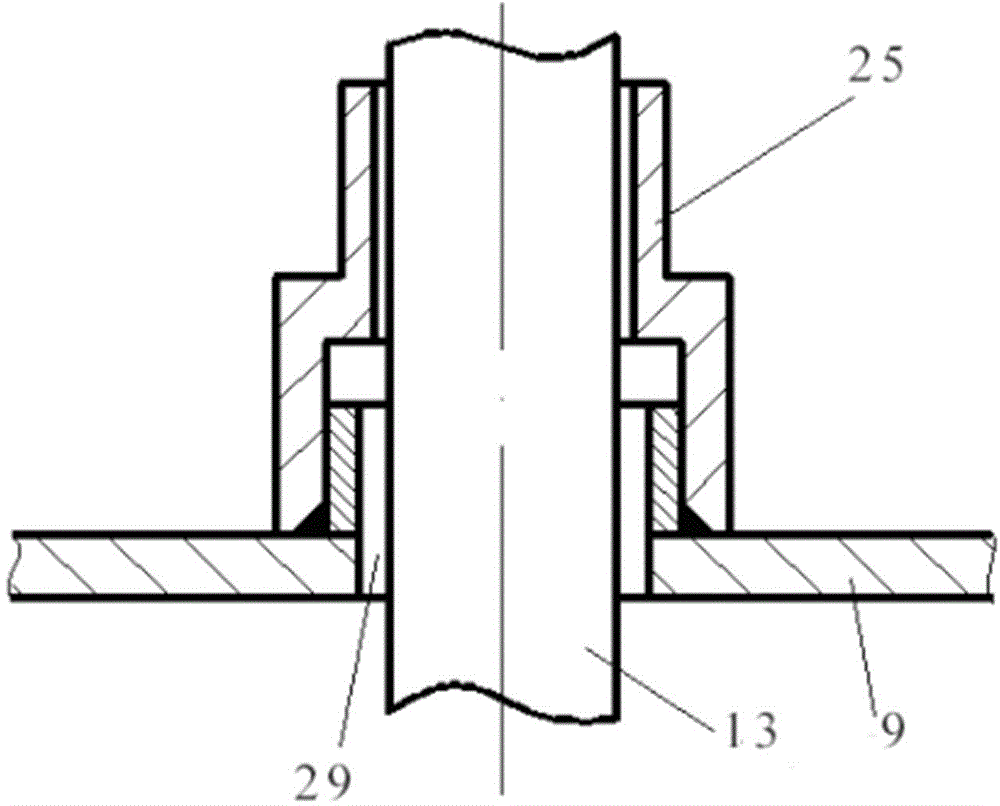

[0058] See attached figure 1 , the high-frequency fatigue life test system includes the vibration excitation device 11 of the fatigue testing machine, the load transfer device 12 and the steam box 9, the steam box 9 is used for the high-temperature steam service environment of the material, the vibration excitation device 11 of the fatigue testing machine, the load transfer device 12 and the steam box 9 are installed on the test frame 10, the load transmission device 12 realizes the cyclic loading of the sample 13, the sample 13 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com