Method for measuring diode transient temperature rise in real time

A technology of transient temperature rise and real-time measurement, applied in the direction of single semiconductor device testing, etc., can solve the problem of inapplicability of transient temperature rise measurement of devices, and achieve the goal of avoiding the influence of temperature rise, eliminating temperature rise error and improving test accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

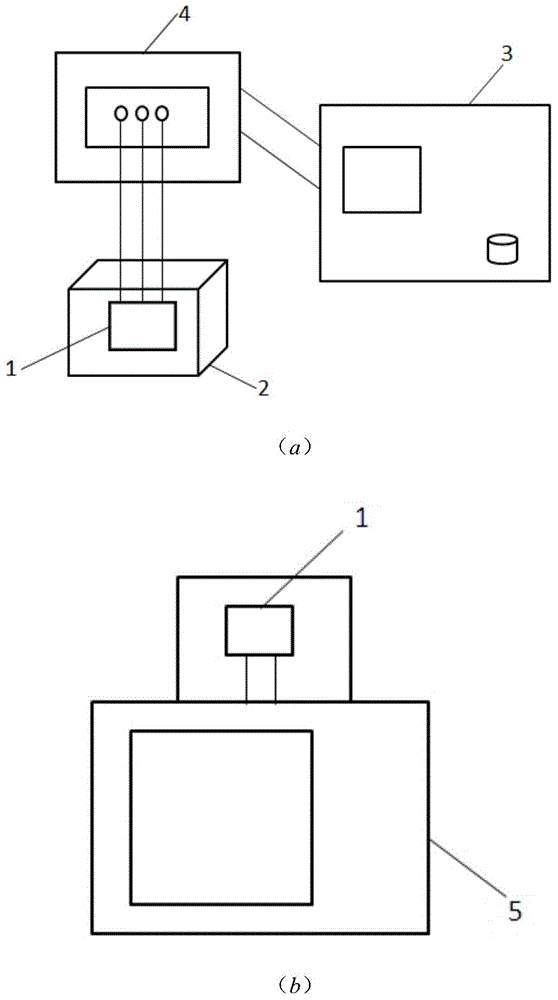

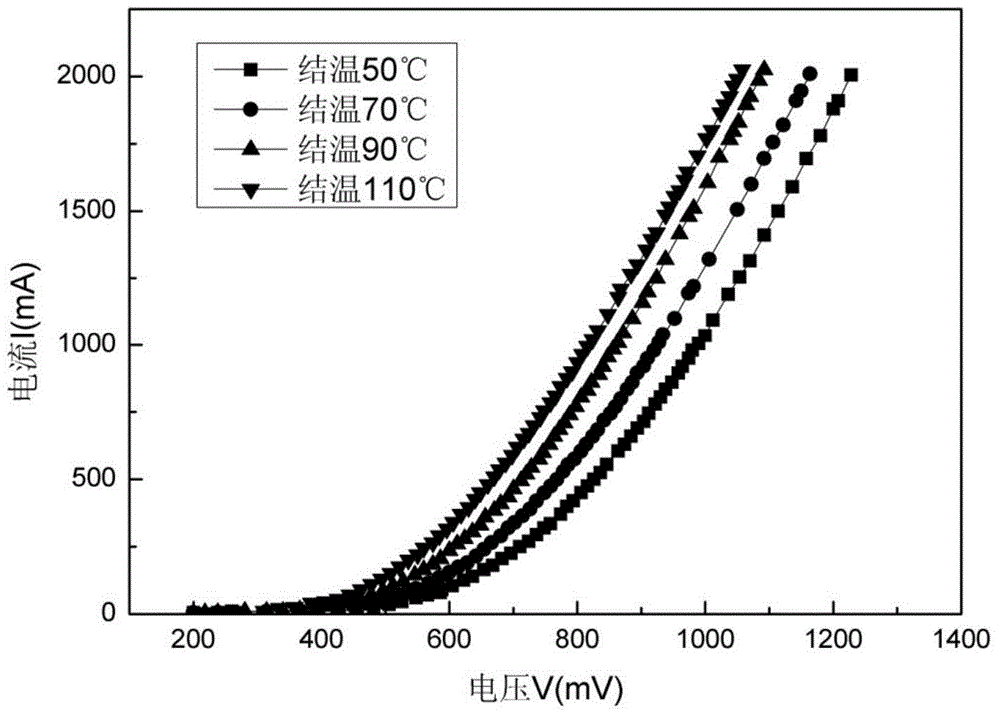

[0026] The testing device involved in the present invention is as figure 1 (a) and (b) shown. It includes a diode 1, a thermostat 2, a graph instrument 3, a device fixture 4 and a semiconductor parameter analyzer 5. Diode 1 is a fast recovery diode, packaged in TO-247-2L type, with a maximum forward voltage of 3.1V and a maximum forward current of 30A. The tracer 3 adopts the Agilent 371A high-power curve tracing instrument. Thermostat 2 uses Despatch900series. Semiconductor parameter analyzer 5 adopts Agilent B1500 precision semiconductor parameter analyzer.

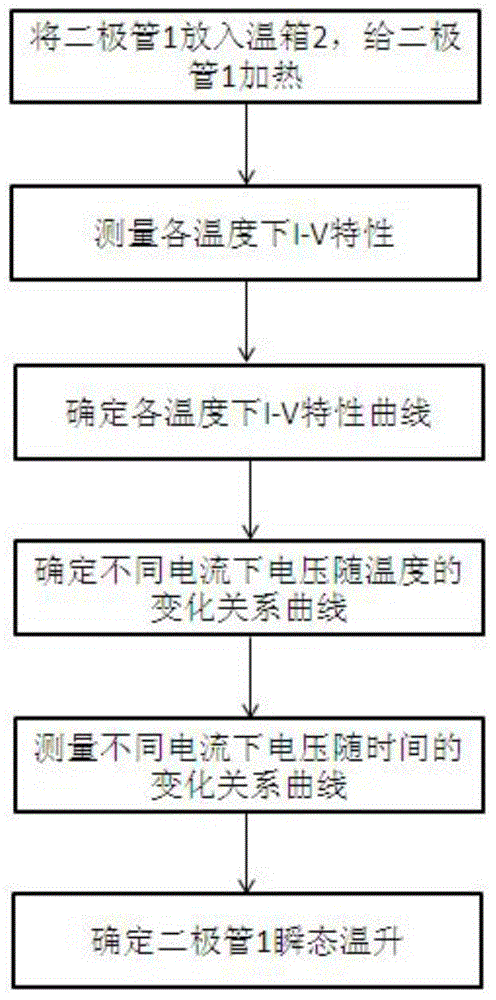

[0027] The flowchart of the method involved in the present invention is as figure 2 shown, including the following steps:

[0028] Step 1, connect the diode 1 with the device fixture 4 of the graph instrument 3 through wires, put the diode 1 into the incubator, and use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com