A temperature compensation circuit applied to laser driver

A technology of temperature compensation circuit and laser driver, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of small occupied area, troublesome application, large occupied area, etc., and achieve stable extinction ratio, save space, and convenient application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

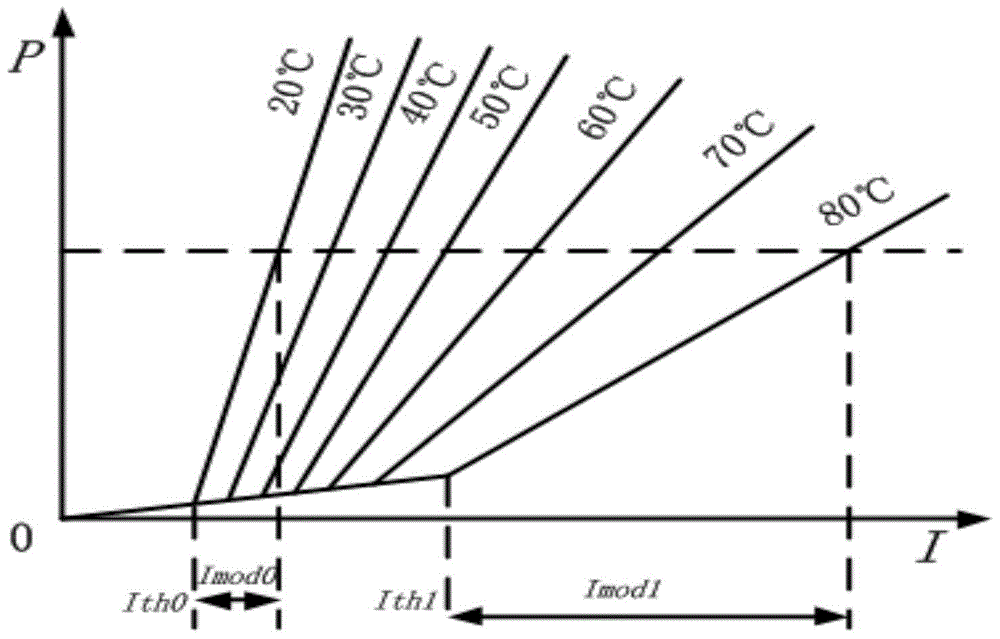

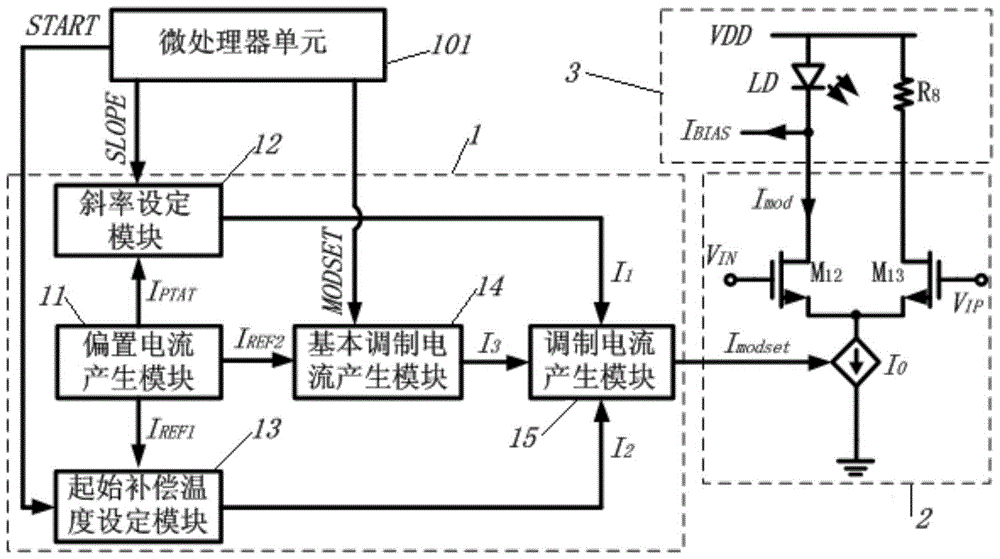

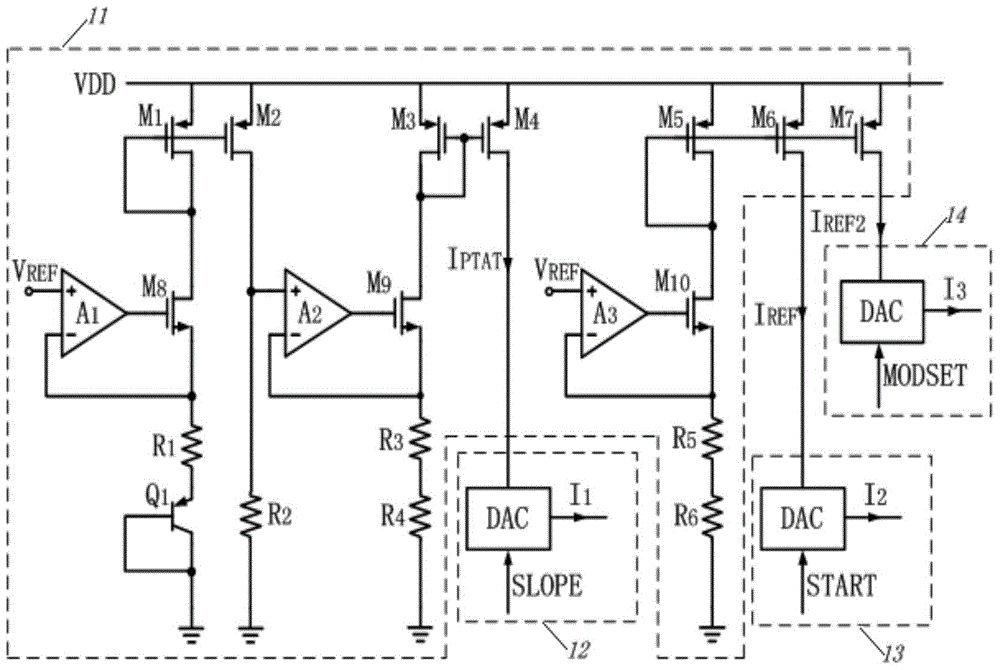

[0028] Such as figure 2 As shown, it is a block diagram of a specific embodiment of the present invention, including a bias current generation module 11, a slope setting module 12, an initial compensation temperature setting module 13, a basic modulation current generation module 14 and a modulation current generation module 15 , the external microprocessor 101 is externally connected.

[0029] The external microprocessor 101 inputs N-bit control words SLOPE, START and MODSET to the slope setting module 12, the initial compensation temperature setting module 13, and the basic modulation current generation module 14 respectively;

[0030] The bias current generation module 11 provides the bias current I that increases with temperature for the slope setting module 12, the initial compensation temperature setting module 13, and the basic modulation current generation module 14, respectively. PTAT , The temperature-independent bias current I REF1 , bias current I REF2 ;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com