Electrolytic cell, in particular for producing aluminum, having a tub-shaped cathode

An electrolytic cell and cathode technology, applied in the field of electrolytic cells, can solve problems such as high resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

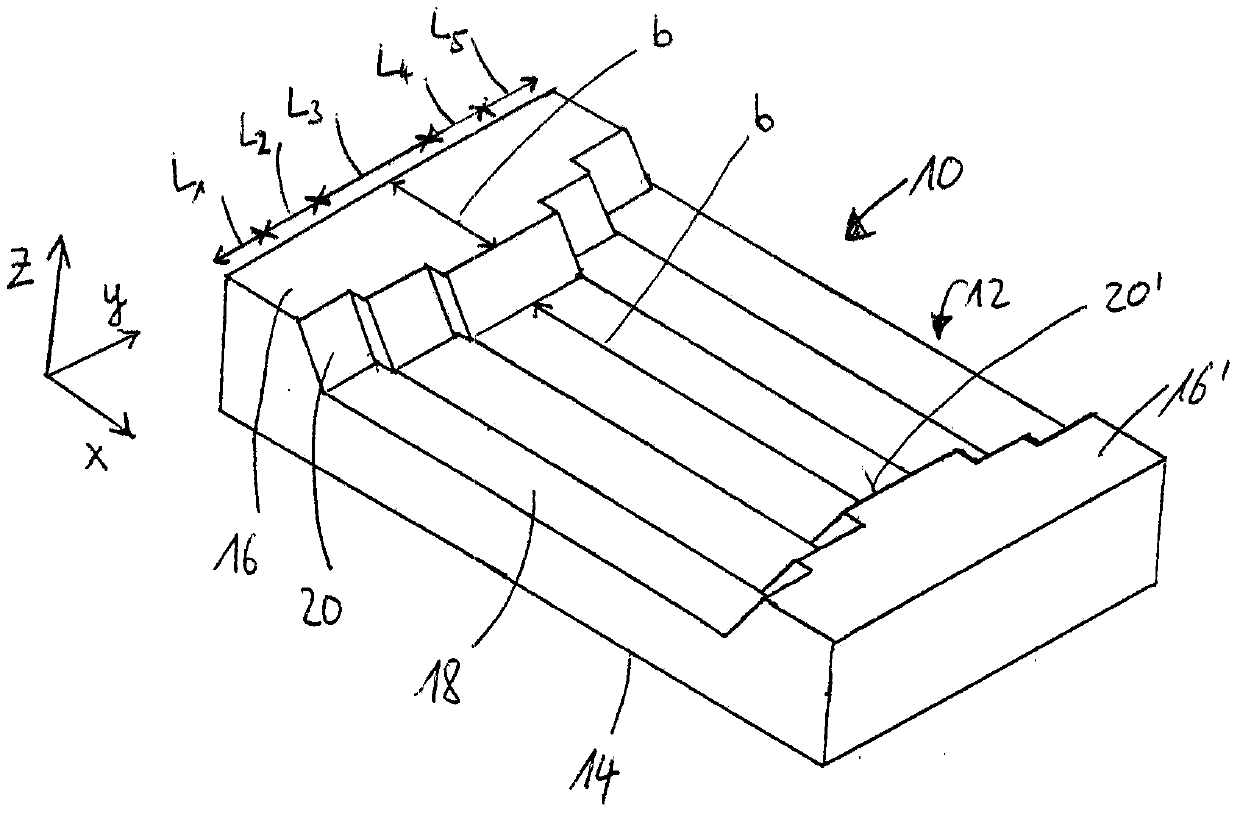

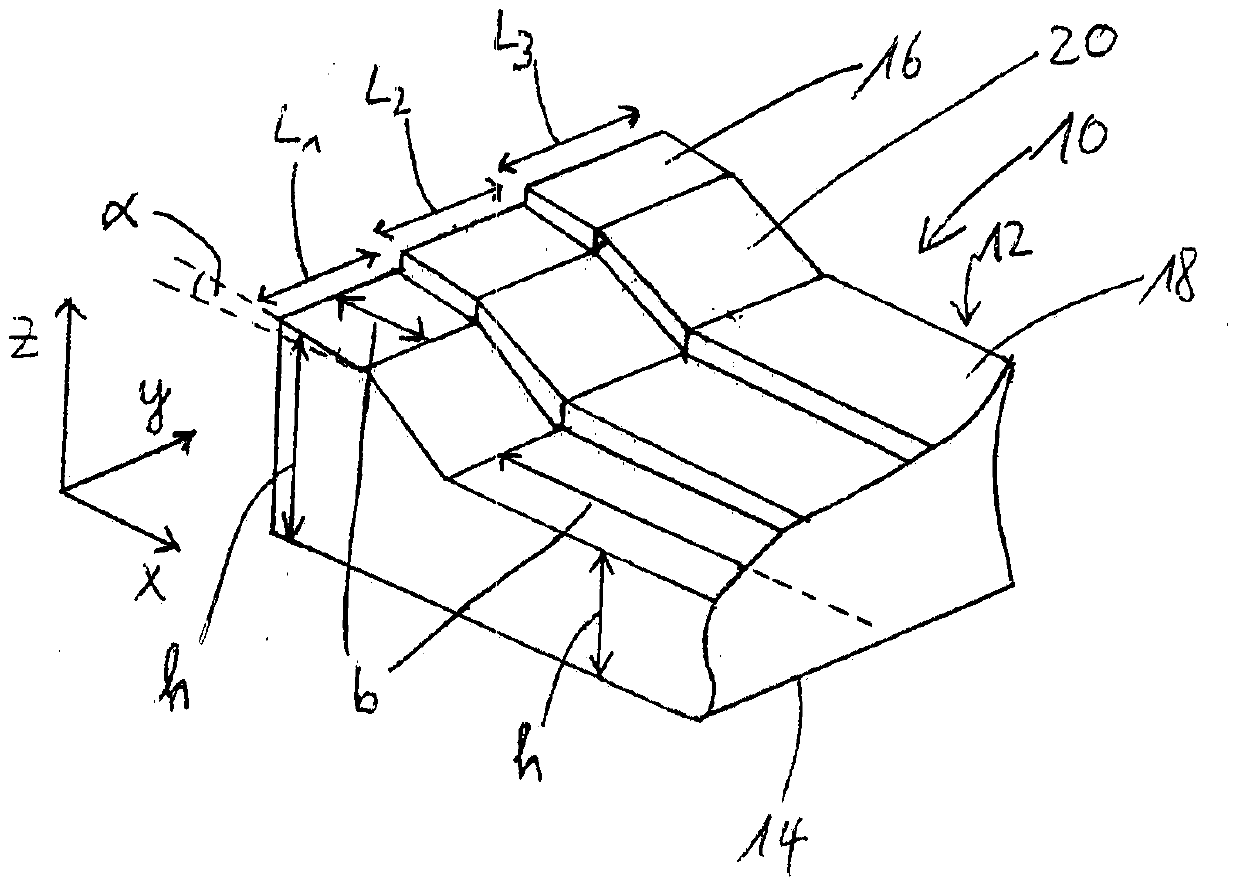

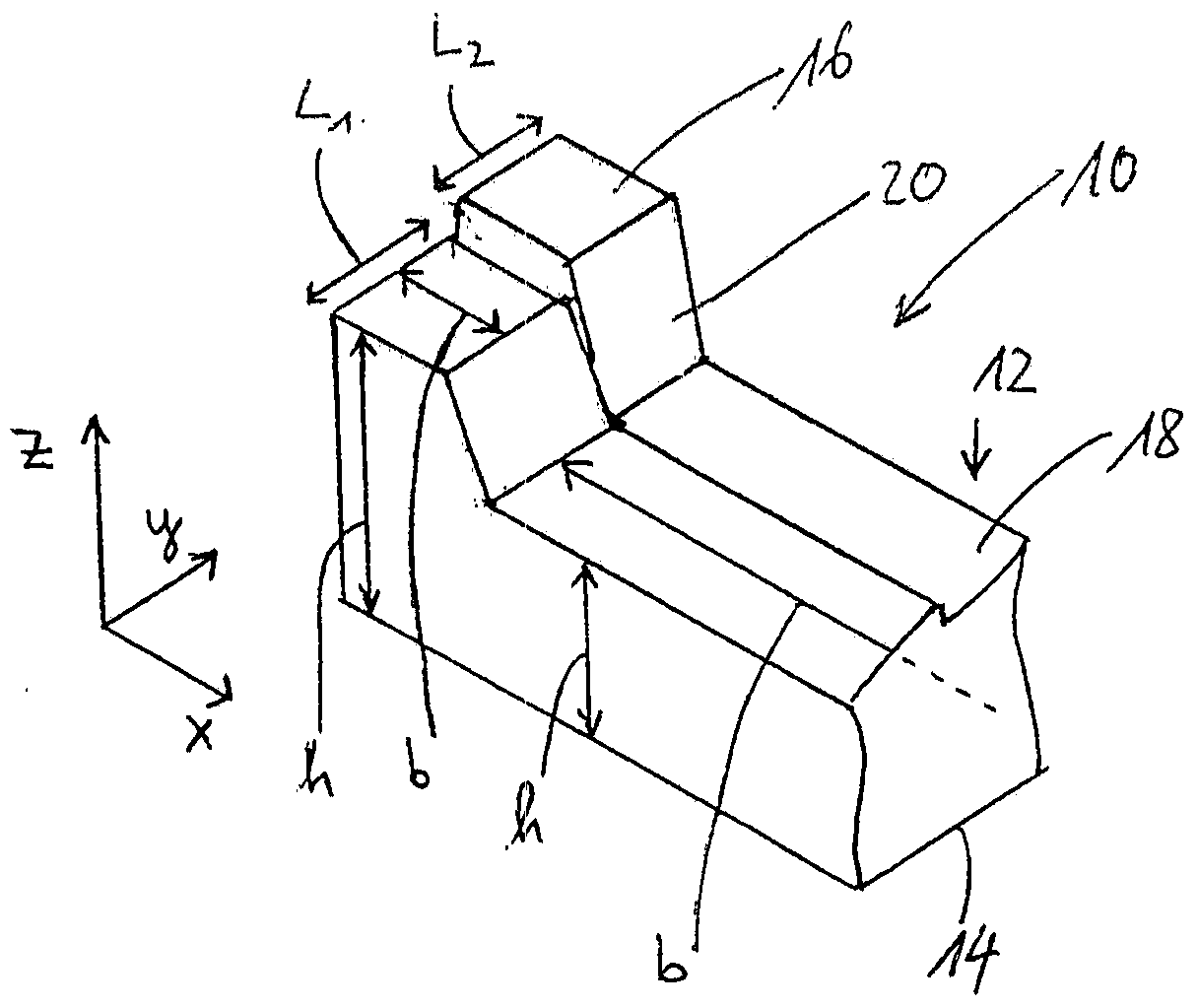

[0049] figure 1 A perspective view of a cathode 10 of an electrolytic cell according to one embodiment of the invention is shown.

[0050] The cathode 10 consisting of a carbonaceous material has an upper side 12 on which the liquid aluminum layer of the electrolytic cell is arranged during operation of the electrolytic cell, for example according to the Hall-Eru process. In practice, the cathode 10 consists of a plurality of cathode blocks arranged side by side as viewed in the longitudinal direction y of the cathode, wherein the longitudinal directions of the individual cathode blocks each extend in the width direction x of the cathode 10 . exist figure 1 Bus bars, not shown, contact the cathode 10 in a current feed from the lower side 14 of the cathode and are conductively connected to at least one external current feed. Here preferably, each busbar is inserted into a groove, which is provided in each cathode block and extends in the width direction x of the cathode 10, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com