Vehicle crash simulation test device and control method for vehicle crash simulation test

A technology for simulation tests and automobiles, applied in the direction of measuring devices, vehicle tests, vehicle impact tests, etc., can solve problems such as high cost, and achieve the effect of improving reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

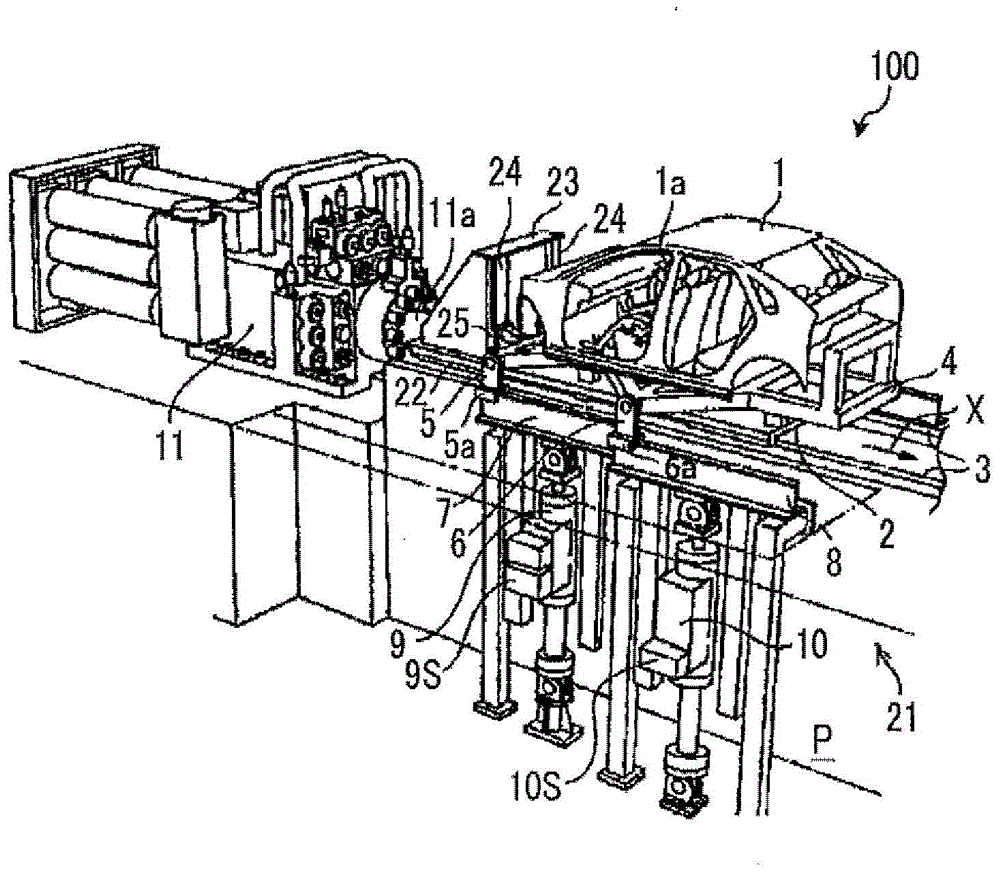

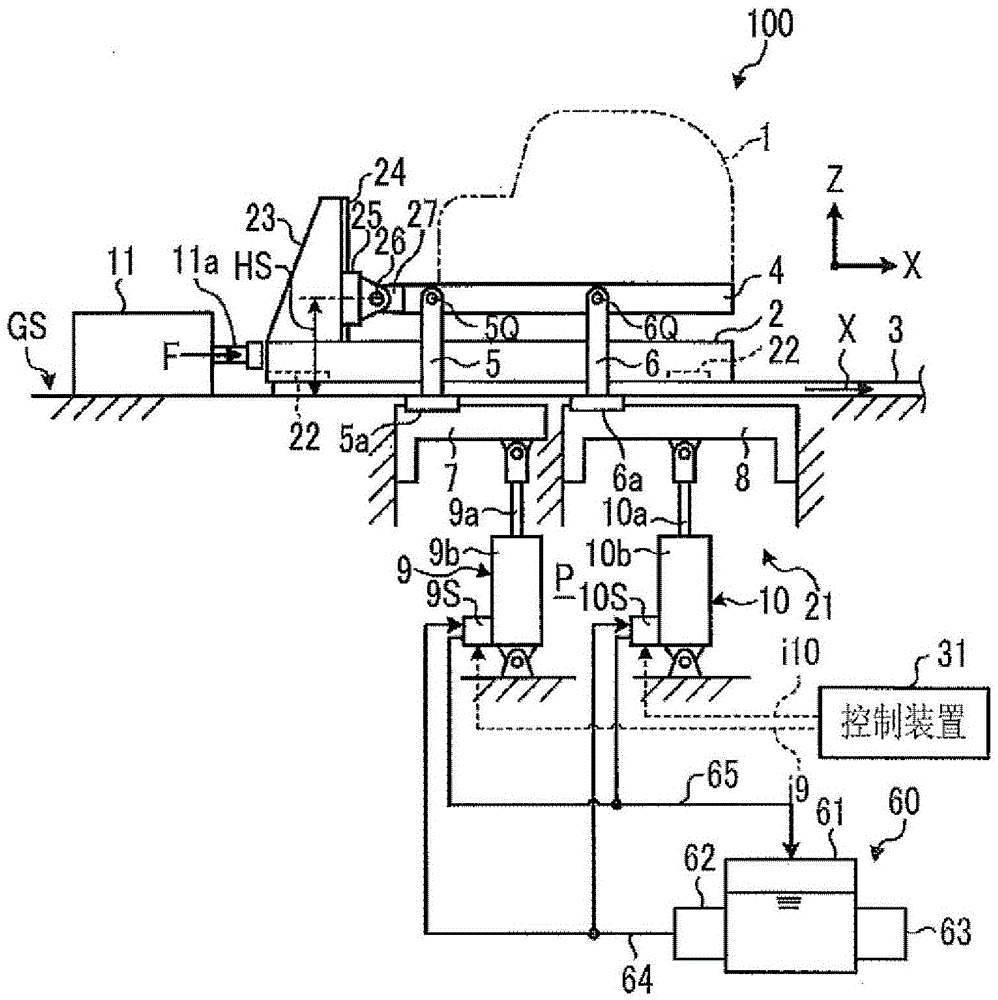

[0035] figure 1 It is a schematic diagram showing the automobile crash simulation test device according to the present embodiment. figure 2 It is a schematic side view schematically showing the automobile crash simulation test device according to the present embodiment. Such as figure 1 and figure 2 As shown, the automobile crash simulation test apparatus 100 according to this embodiment includes a carriage 2 capable of mounting a test piece 1 , a carriage acceleration device 11 , and a pitching device 21 for imparting a pitching motion to the test piece 1 . A pair of left and right rails 3 are attached to the floor GS along the front-rear direction with predetermined intervals therebetween. The pitch device 21 is disposed in a groove P that is a space below the rail 3 .

[0036] The test piece 1 is mounted on the carriage 2, so the front of the automobile as the test piece 1 ( figure 2 The left direction of the carriage 2) is set as the front of the carriage 2, and th...

no. 2 Embodiment approach

[0081] Next, the automobile collision simulation test device 100 according to the second embodiment will be described. In the second embodiment, the vehicle collision simulation test apparatus 100 does not operate the second vertical drive actuator 9 . Figure 8 It is an explanatory diagram for explaining the test piece height during the operation of the automobile collision simulation test device according to the second embodiment. In the following description, the same reference numerals are assigned to the same components as those in the above-mentioned embodiment, and repeated descriptions will be omitted.

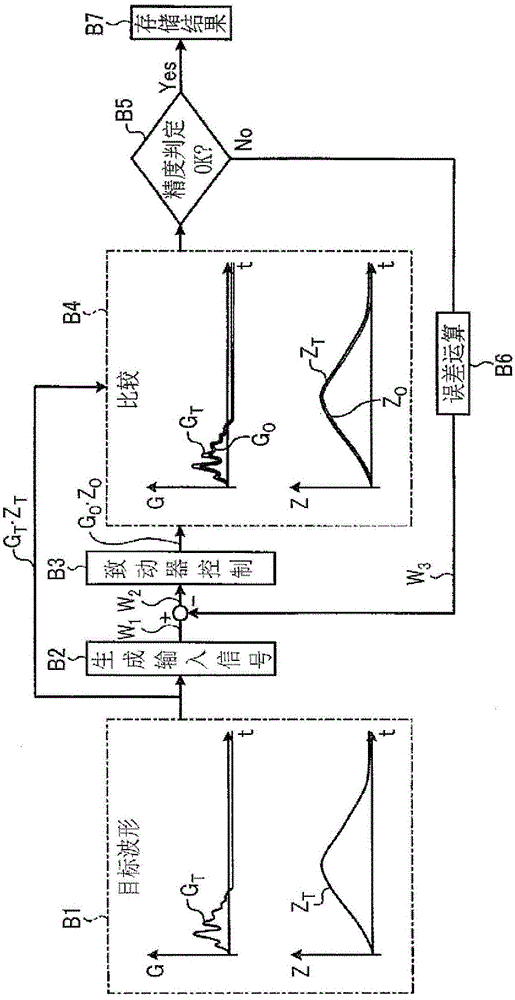

[0082] First, in the automobile collision simulation test apparatus 100 according to the present embodiment, a target acceleration (deceleration acceleration in the forward direction of the carriage 2 and the test piece 1) is applied to the carriage 2 in a stopped state arranged in contact with the front end of the piston 11a. ), the hydraulic device is controlled by ...

no. 3 Embodiment approach

[0095] Next, the automobile collision simulation test device 100 according to the third embodiment will be described. In the third embodiment, the vehicle crash simulation test device 100 includes an extension rail extending the length of the rear lift rail 8 for raising and lowering the first vertical drive actuator 10 . Figure 9 It is a schematic side view schematically showing the automobile crash simulation test device according to the third embodiment. In the following description, the same reference numerals are assigned to the same components as those in the above-mentioned embodiment, and repeated descriptions will be omitted.

[0096] As described above, when the shoe 6a passes through the rear elevation rail 8, it moves up and down according to the elevation of the first vertical drive actuator 10. As shown in FIG. Since the acceleration applied during the upward movement of the first vertical drive actuator 10 which is the pitching movement of the test piece 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com