Contactless electric power supply device

A non-contact power supply, non-contact technology, applied in the direction of electromechanical devices, circuit devices, along the track device, etc., can solve the problems of sliding power supply part wear, metal fatigue, etc., achieve low cost and avoid mutual interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

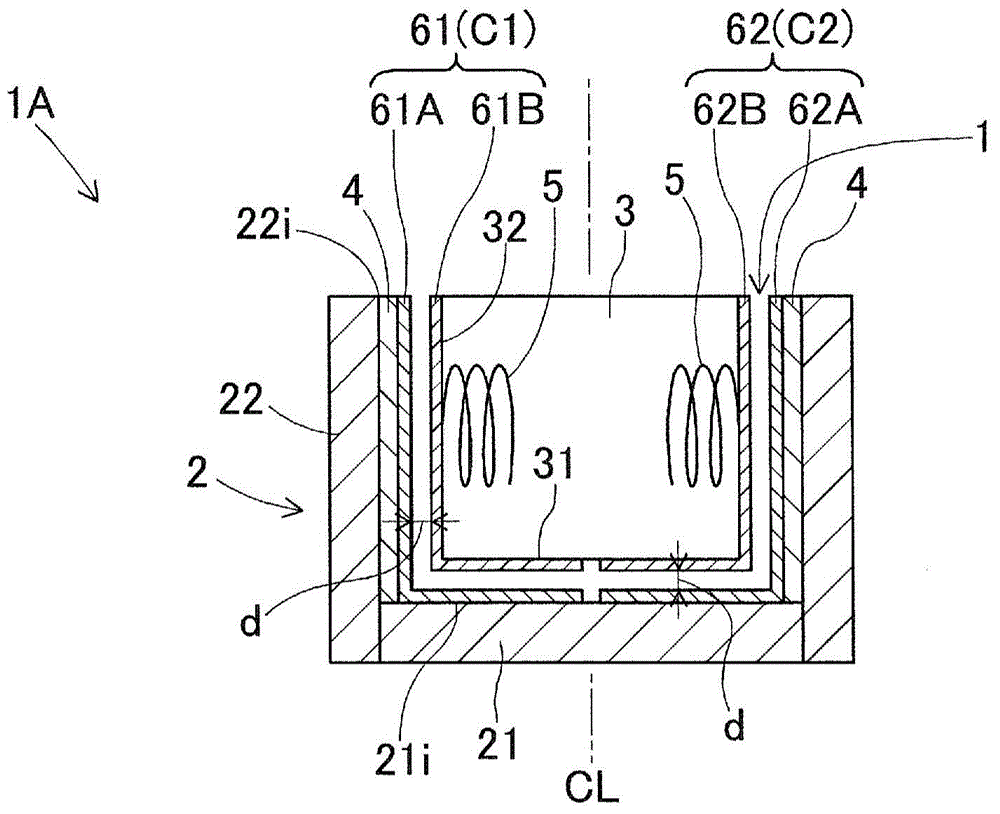

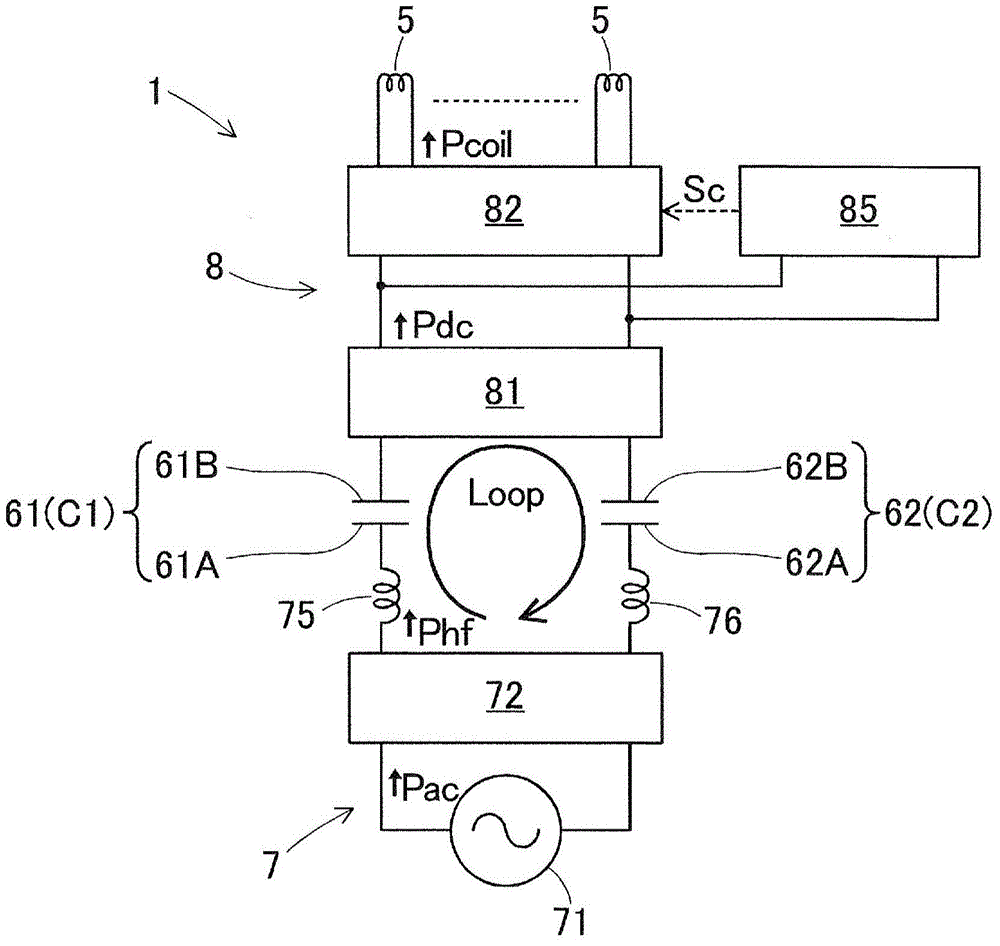

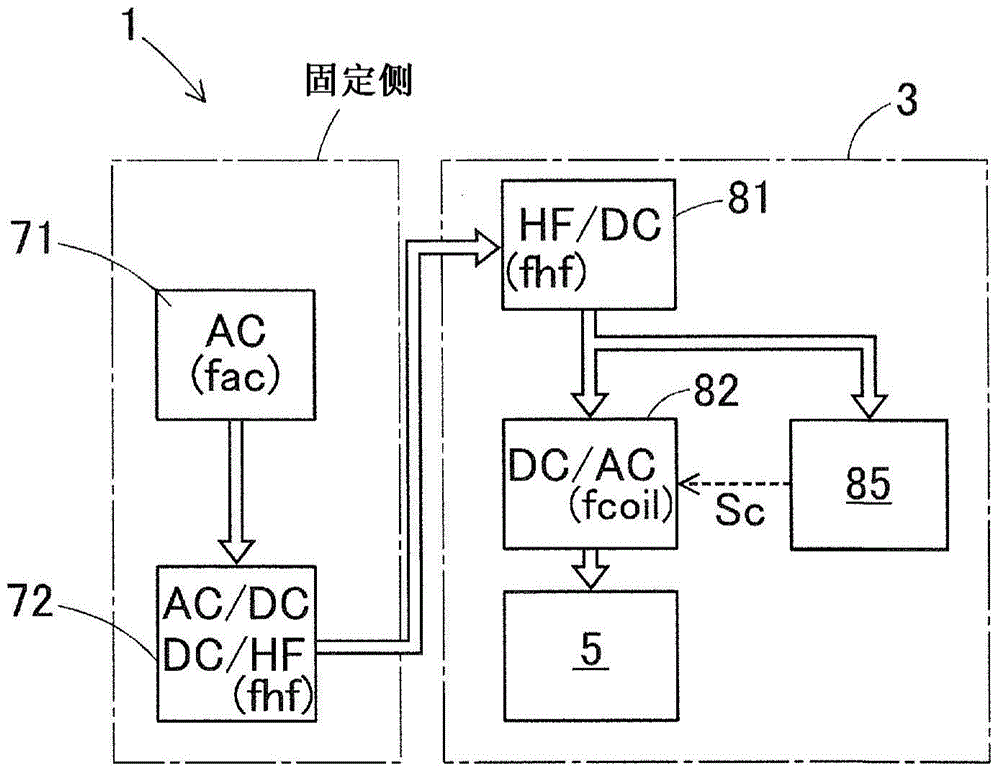

[0032] Before describing the embodiment, a general conventional linear motor device 9 will be described first. Figure 5 It is an explanatory drawing schematically explaining the structure of the conventional linear motor apparatus 9. The linear motor device 9 is constituted by a rail 91 , a moving body 92 , a plurality of magnets 93 , a plurality of coils 94 , a power supply cable 95 , and the like.

[0033] The rail 91 is a rail member extending along the moving direction of the moving body 92 . track 91 in Figure 5 , extending from the left front side to the right inner side along the moving direction M shown by the hollow arrow. The bottom plate 911 and the two side plates 912 and 913 are integrated to form the rail 91 . The cross-sectional shape of the rail 91 perpendicular to the moving direction is a groove shape opening upward. The moving body 92 has a substantially box shape and is mounted on the rail 91 so as to be movable. The mobile body 92 is attached to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com