Coiler wrapper roller ladder-speed control method and control system thereof

A technology of speed control and control system, which is applied in the field of stepwise speed control of coiling-assisting rollers of coilers, and can solve problems such as insufficient tightness of the inner ring of hot-rolled steel coils, large leading ratio of coiling-assisting rollers, and large strip tension. Reach the effects of reducing the contusion defect of the inner ring, reducing the narrowing of the strip width, and reducing the coil defect of the strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

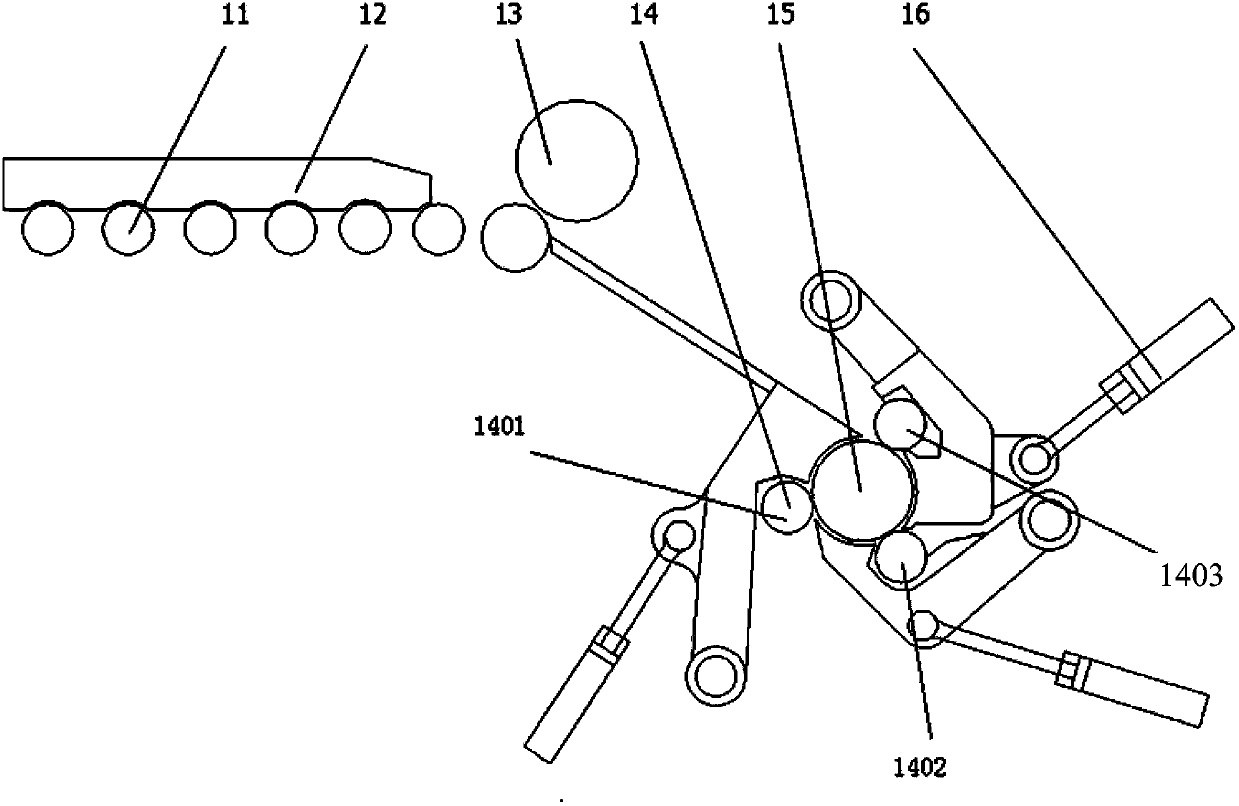

[0104] A preferred embodiment of the method for controlling the stepwise speed of the coiler of the present invention, comprising the following steps:

[0105] S100) The strip 7 enters the first stand of the finishing mill 2, and the secondary computer 3 obtains the hardness and thickness data of the strip 7 after receiving the steel bite signal from the first stand of the finishing mill, and passes the coiling temperature The coiling temperature obtained by the thermometer in real time determines the hardness level, thickness level and coiling temperature level of the strip.

[0106] Wherein, the hardness level judging module 301 determines the hardness level of the strip according to the hardness of the strip according to the following conditions:

[0107] The strip steel hardness of the first hardness level is 200-250N / mm 2 ;

[0108] The strip steel hardness of the second hardness level is 250-300N / mm 2 ;

[0109] The strip steel hardness of the third hardness level is...

Embodiment

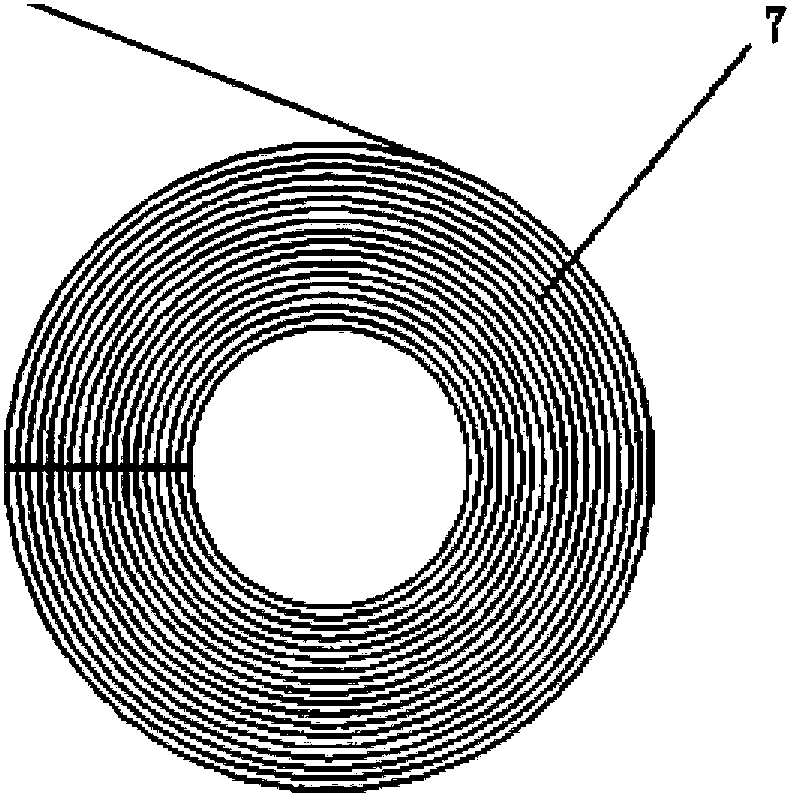

[0155] Assume that the strip 7 entering the finishing stand has a yield strength of 520N / mm 2 , the thickness is 4.5mm, and the coiling temperature level is 630°C;

[0156] According to the step S100 of the present invention, the secondary computer 3 acquires the actual hardness, thickness and coiling temperature of the steel strip 7, and queries the above-mentioned hardness, thickness and coiling temperature level data table (Table 1-3) according to the range of the value. , determine that the hardness group level of strip 7 is 7, the thickness level is 3, and the coiling temperature level is 2.

[0157] According to step S200 of the present invention, the secondary computer 3 looks up the table from Tables 5 to 6 according to the hardness level, thickness level and coiling temperature level of the strip steel 7 to determine the corresponding hardness lead rate adjustment parameter X1=2%, and the thickness lead rate Rate adjustment parameter X2=1.5%, coiling temperature lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com