Electroplastic forming method and device for bulk metallic glass workpiece

A bulk metal, electroplastic technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of uneven mechanical properties, difficult processing of bulk metal glass, etc., to avoid crystallization and maintain unique properties , the effect of improving the plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

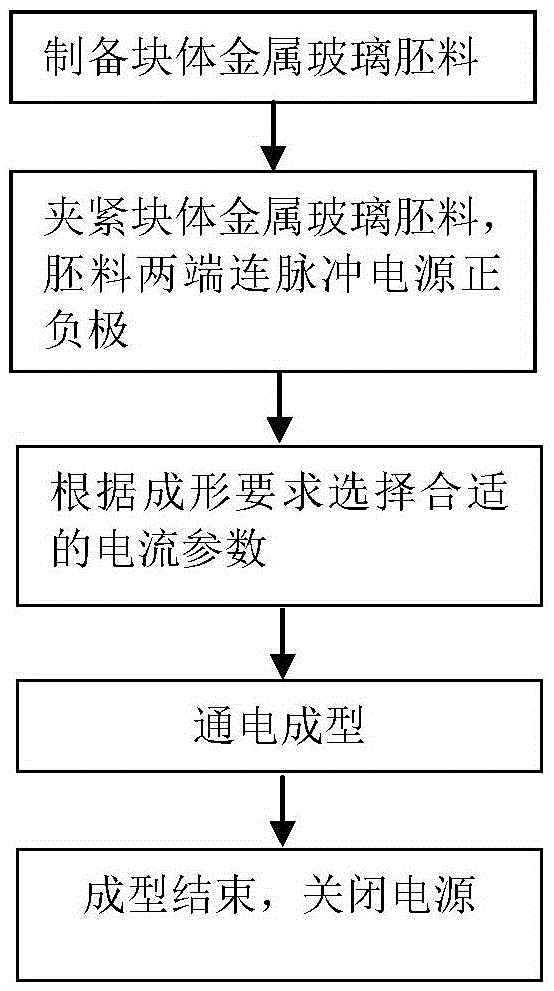

Method used

Image

Examples

Embodiment 1

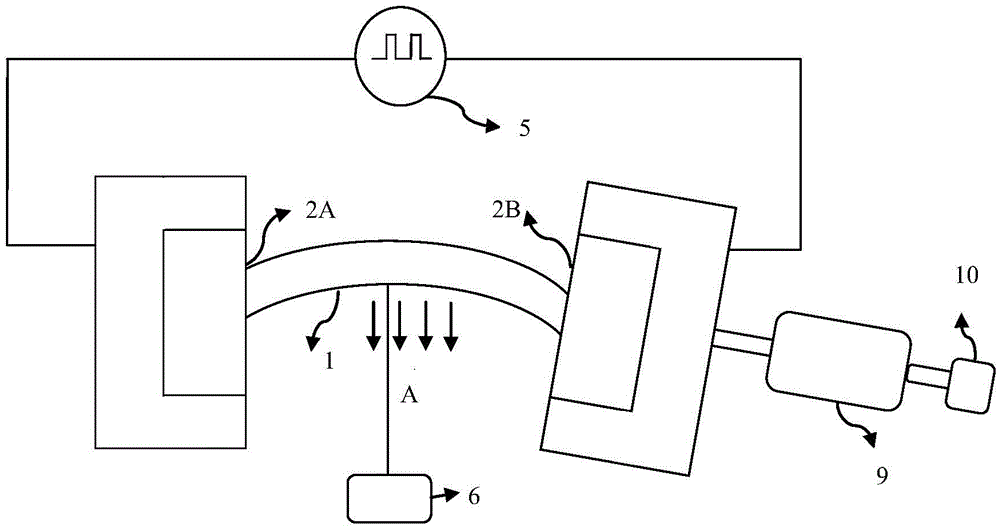

[0032] Such as image 3 Said, this example uses Zr 55 Cu 30 Al 10 Ni 5 (Atomic percentage) Bending processing of bulk metallic glass rod blanks at 200°C is an example, and the specific steps are as follows:

[0033] Zr-based metallic glass is machined into a bulk metallic glass rod-shaped blank 1 with a uniform cross-section, and the bulk metallic glass rod-shaped blank 1 is placed between a first fixture 2A and a second fixture 2B made of oxygen-free copper , adjust the positions of the first fixture 2A and the second fixture 2B so that they fit and clamp the bulk metallic glass rod-shaped blank 1, so as to ensure that the first fixture 2A and the second fixture 2B are always in contact with the bulk metallic glass rod-shaped blank 1 during the molding process. Blank material 1 is in good contact;

[0034] Set the pulse current parameters. According to the volume of the bulk metallic glass blank, the pulse parameters are selected: the current size is 100-1000A / mm 2 , th...

Embodiment 2

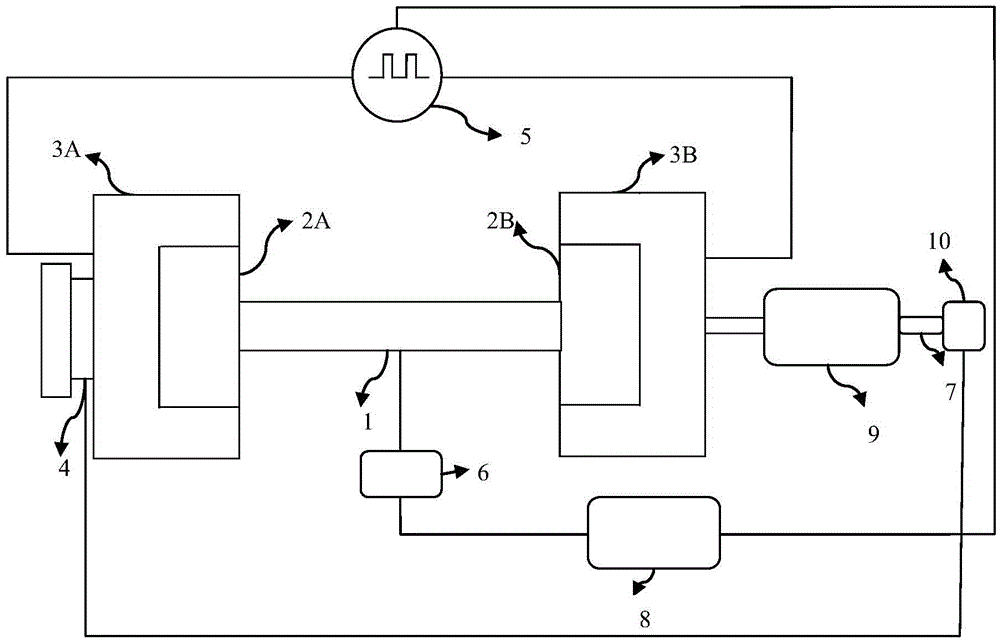

[0041] Such as figure 2 As shown, a device for realizing electroplastic forming of bulk metallic glass includes a first clamp 2A, a second clamp 2B, a pulse current source 5, a first electrode clamp 3A, a second electrode clamp 3B, a temperature sensor 6, a temperature Controller 8 , displacement sensor 7 , actuator 9 and actuation controller 10 .

[0042] Wherein, the front of the first fixture 2A and the front of the second fixture 2B are always attached and clamped to the bulk metallic glass blank 1 placed between them, so as to fix the bulk metallic glass blank and transmit current; The back of the first clamp 2A is fixedly connected to the front of the first electrode clamp 3A, and the back of the first electrode clamp 3A is electrically connected to the positive pole of the pulse current source 5; the back of the second clamp 2B is connected to the second The front of the electrode clamp 3B is fixedly connected; the back of the second electrode clamp 3B is electrically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com