Tilting device for ingot casting with rectangular section

A technology of rectangular cross-section and turning machine, which is applied in the fields of metallurgical casting and vacuum metallurgy, which can solve the problems of time-consuming and laborious, unsuitable for ingot turning requirements, and difficult accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A rectangular cross-section ingot turning machine related to the present invention has been successfully used in the turning process of titanium ingots in this unit.

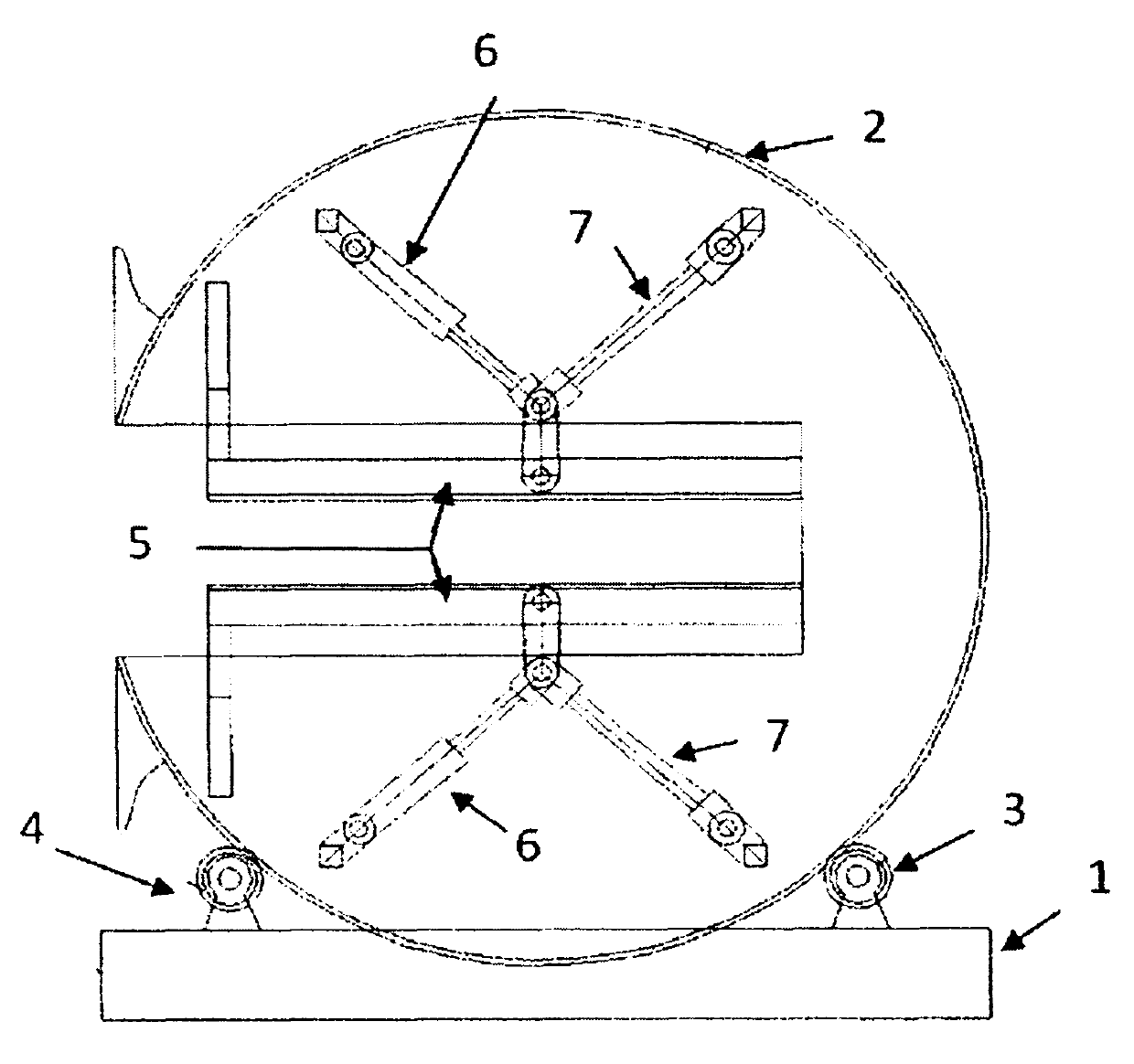

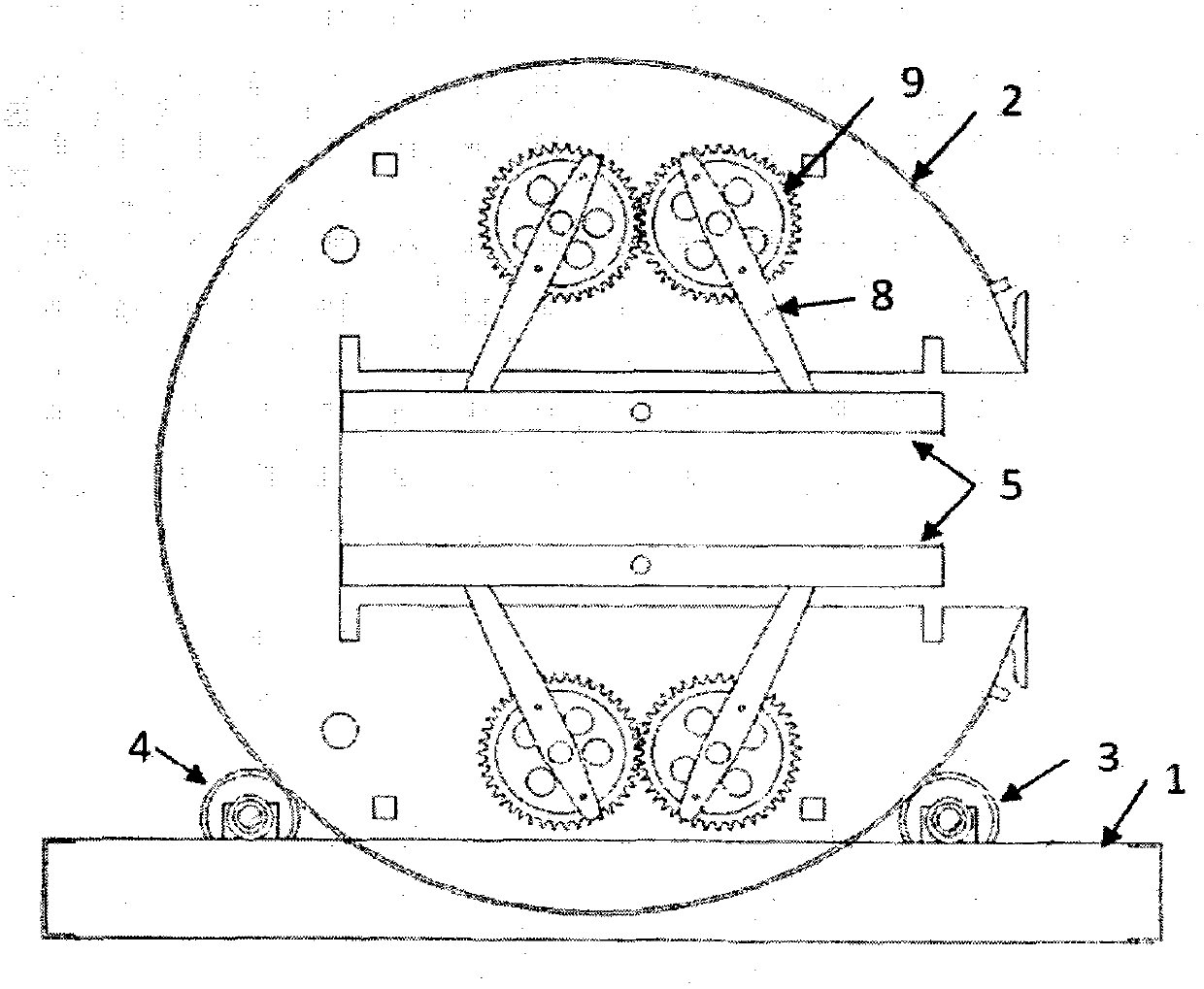

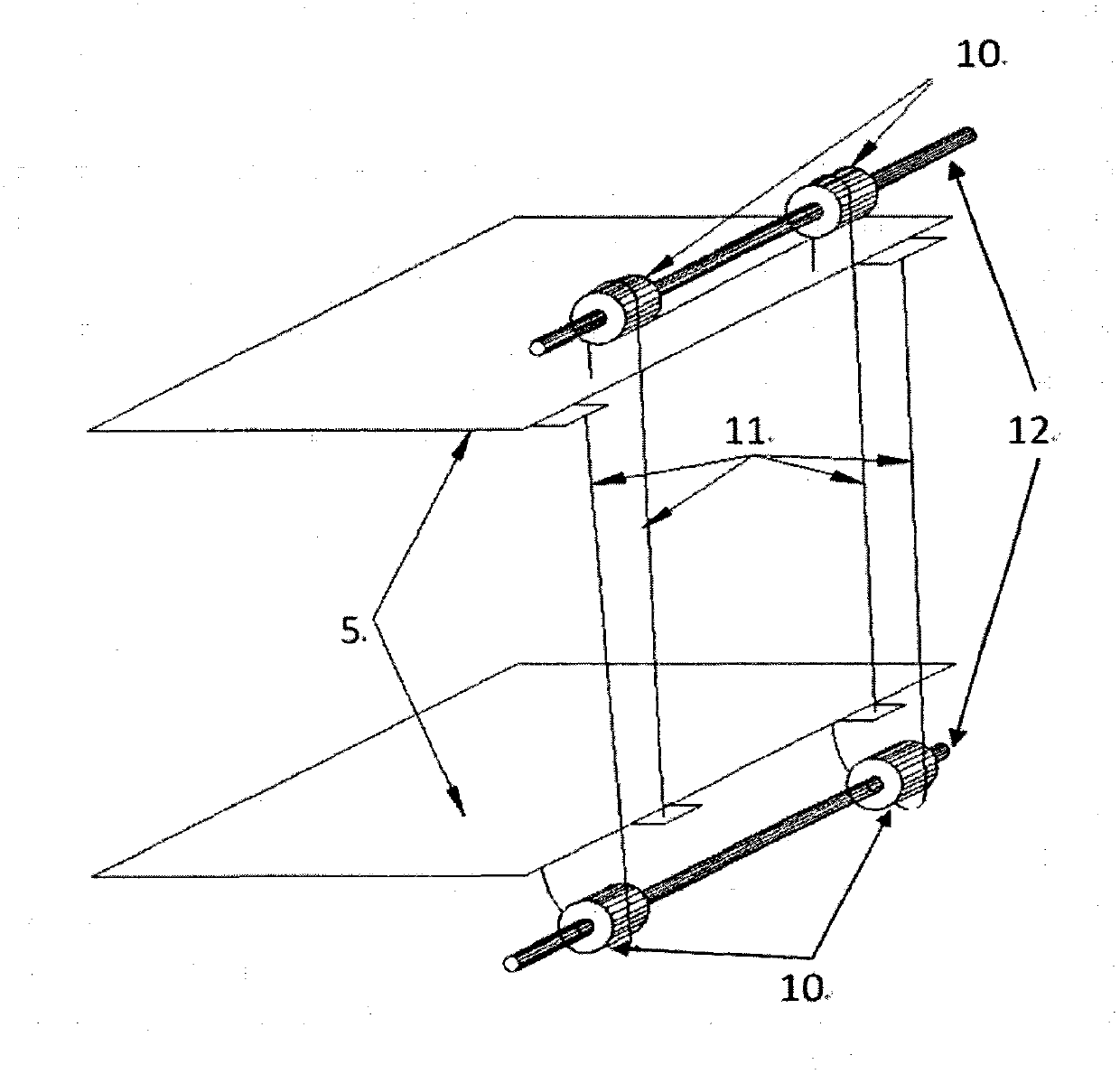

[0010] The turning machine is installed on the underframe (1) with a metal structure drum (2) of a certain length, and the roller is installed on the underframe (1) on the load-bearing wheels (3), as a support point, the load-bearing drive wheel (4), It is fixed on the bottom frame (1) and provides another supporting point and turning driving force for the drum (2). The jaw plate (5) is used to clamp the ingot, and the hydraulic cylinder (6) is a double herringbone clamping arm. The support arm (7) is a gravity component. The support arm (8) is the force transmission part of the double herringbone clamping unit. Gear (9), chain gear (10), chain (11), sprocket shaft (12) plays a transmission effect, and sprocket shaft also makes two pairs of synchronous chain synchronous actions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com