Intelligent planet-tracking synchronous liquid spraying and gas absorbing device for curved surface electrolytic machining

A technology of suction device and curved surface, which is applied in the field of green environmental protection electrolytic grinding and can solve the problems of environmental pollution and danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

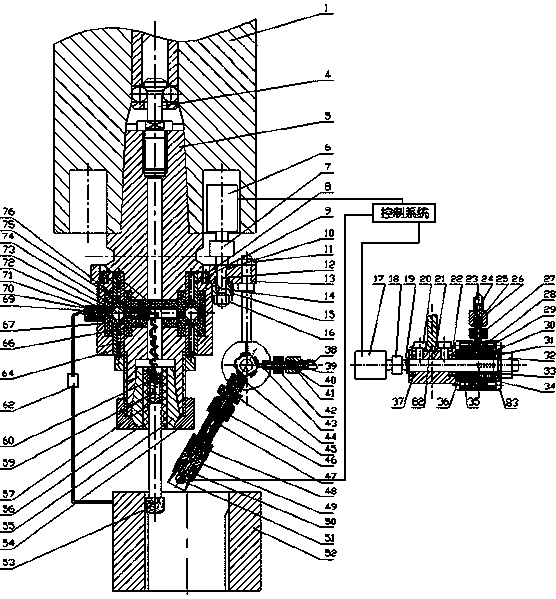

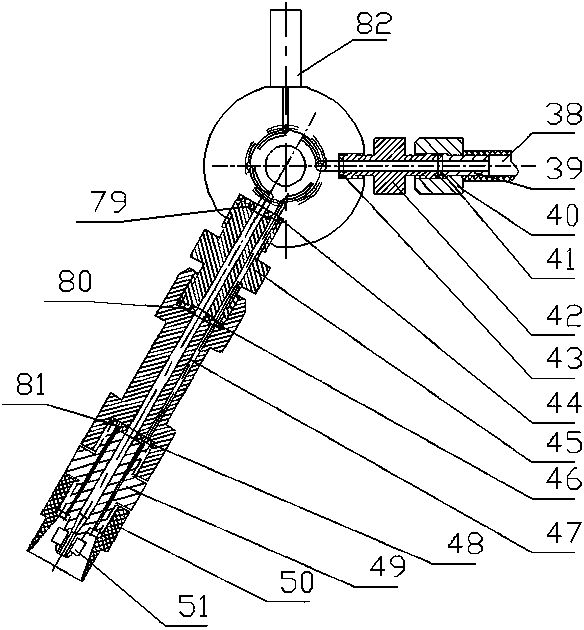

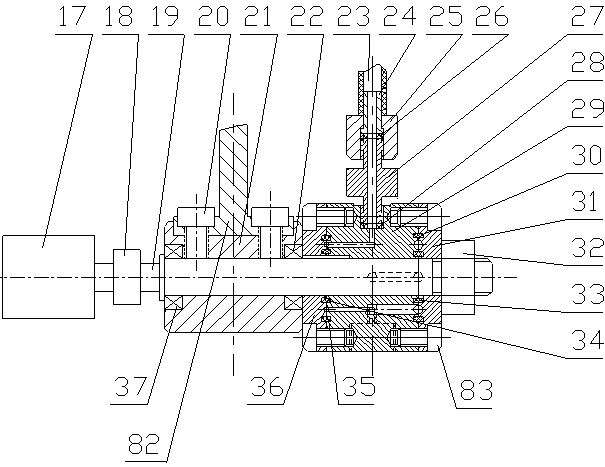

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 Shown is a schematic diagram of the structure of the liquid spraying and suction device of the present invention when it is used for electrolytic grinding. The electrolytic grinding adopts an integrated insulated numerical control electrolytic grinding processing chuck arranged on the numerical control machine tool 1 (for the specific structure, refer to the invention with the publication number CN103465078A patent), mainly consists of chuck handle body 5, needle bearing 8, insulating plugs 60, 66, outer insulating ring 67, inner insulating ring 75, outer conductive ring 72, inner conductive right half ring 74, conductive balls 57, 71 , 73, 76, external fixation sleeve 64, insulating plug 69, 70, conductive wire 59, spring clip 55, fastening nut 54, diamond grinding head 53, insulating opening ferrule 56, pull nail 4, mold 52, power supply 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com