Gas-shielded flux-cored welding wire for arc welding

A technology of gas shielding and flux-cored welding wire, applied in arc welding equipment, welding medium, welding equipment, etc., can solve problems such as unsatisfactory welding, unachievable welding, and inability to fully meet the welding requirements of marine steel, so as to reduce diffusion The effect of hydrogen and oxide slag content, less cracks, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

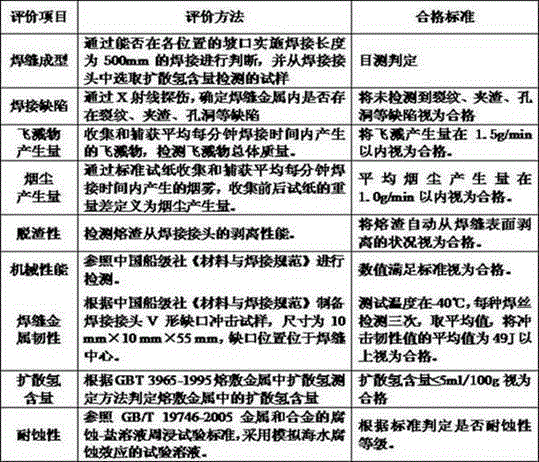

[0020] Table 1 shows the components and mass percentages of the flux-cored welding wire of the present invention.

[0021] Table 1 Flux cored wire components and mass percentage (%)

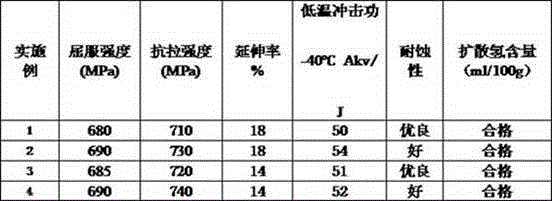

[0022] Example TiO 2 SiO 2 ZrO 2 al 2 o 3 MgO AlF 3 NiF 2 Na 2 SiF 6 1 20 4 2.5 2 1.5 8 6 4 2 20 4 2.5 3 1.5 8 6 4 3 22 3 2 1.5 1.5 9 5 4 4 22 3 2 2.5 1.5 9 5 4 Example Ti 3 Al Fe 3 Al co Cu Ce Nd SM Gd 1 4 4 1.7 0.1 0.1 0.1 - - 2 3 5 1 - - - - - 3 4 5.8 1.9 0.1 - - 0.1 0.1 4 3 6 2 - - - - -

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com