A synchronous belt lifting and transferring mechanism for automatic tire production line

An automatic production line, lifting and transferring technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of lack of adjustability, slippage, unstable transmission ratio, etc., to reduce maintenance time and cost, simple structure and principle , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

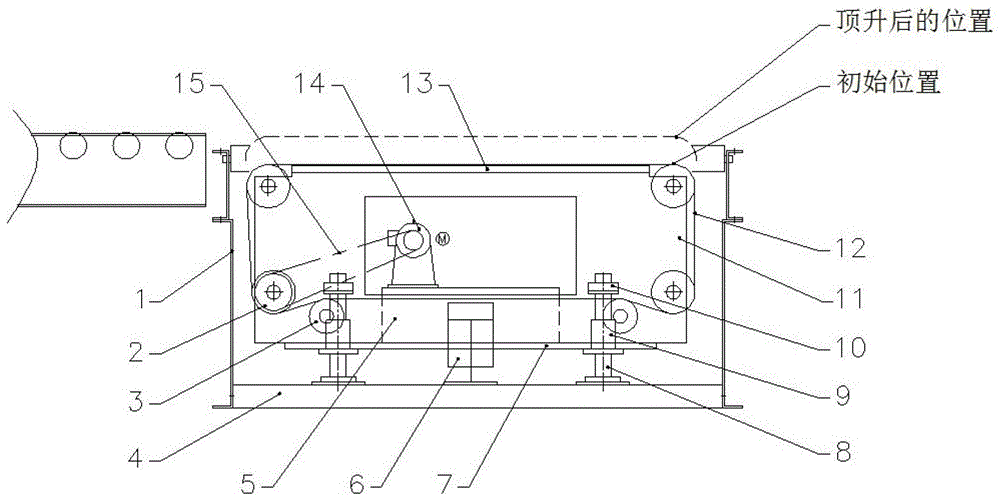

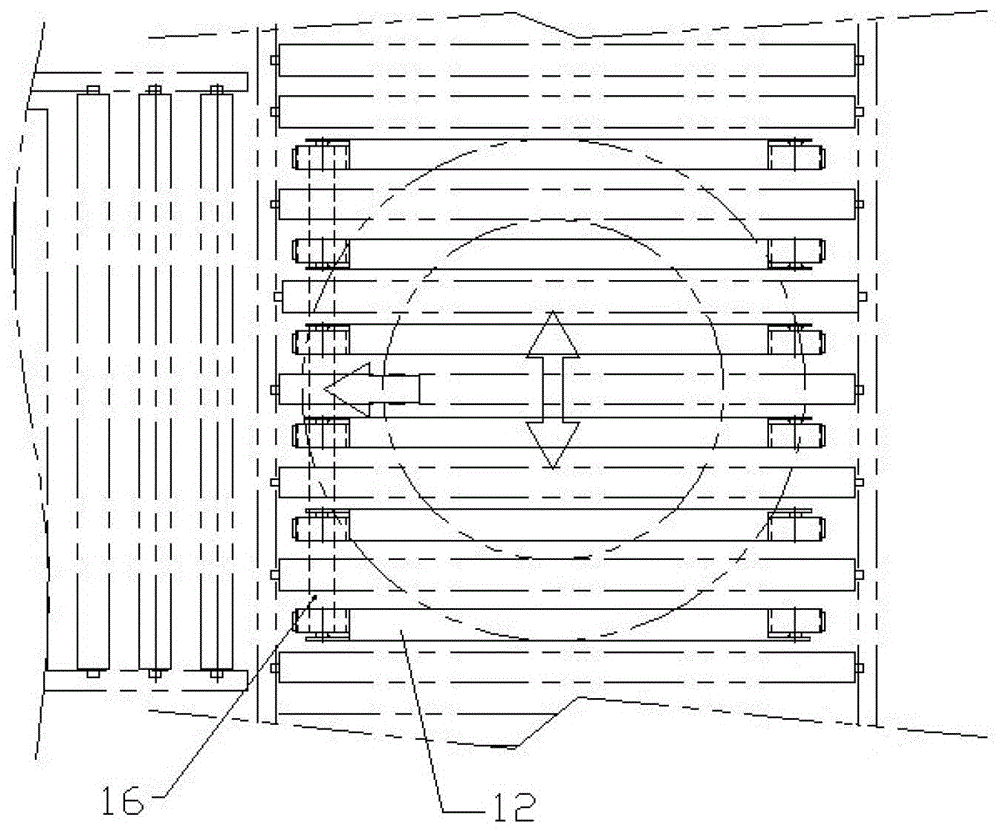

[0026] A synchronous belt lifting and transferring mechanism for automatic tire production line, its structure is as follows: Figure 1-2 As shown, it includes a base, a guide component and a transplanting device, wherein the base includes a cylinder base 4 and base connecting plates 1 arranged on both sides of the cylinder base 4 . The guide parts ensure the vertical movement and limit of the transfer device during the lifting process, including the guide shaft 8, the linear bearing 9 and the buffer ring 10, the guide shaft 8 is installed on the cylinder base 4, and the linear bearing 9 is set on the guide shaft 8, the buffer ring 10 is arranged on the top of the guide shaft 8. The transplanting device comprises a cylinder 6, a movable base plate 7, a motor base 5, a motor 14, a driven shaft 16, a chain 15 and a synchronous belt pulley group, and the synchronous belt pulley group is formed by connecting four synchronous belt pulleys 2 looped through a synchronous belt 12. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com