A kind of heat-resistant sliding block of steel rolling heating furnace

A technology of heat-resistant slide block and heating furnace, which is applied to heat treatment furnaces, furnaces, furnace types, etc., can solve the problem of increasing production and reducing consumption, reducing the time and number of shutdowns of heating furnaces, and the heat transfer of heat-resistant slide blocks and longitudinal water pipes. Defect and other problems, to achieve the effect of eliminating thermal expansion force, uniform force, reducing times and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

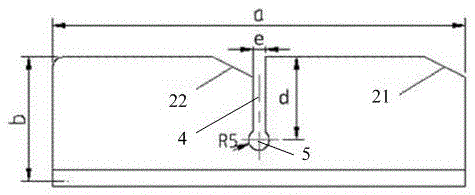

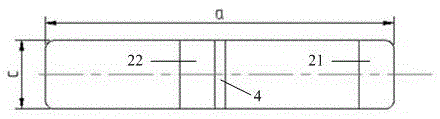

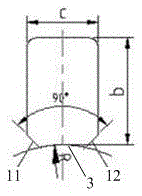

[0019] In order to better illustrate the present invention, a preferred embodiment is hereby combined with the attached figure 1 , figure 2 and image 3 The present invention is described in detail, specifically as follows:

[0020] see figure 1 , figure 2 and image 3 , is a heat-resistant slider for a steel rolling heating furnace of the present invention, and the heat-resistant slider is cast from heat-resistant steel. The general size of the heat-resistant slider is: the length a of the slider is 160-200 mm, the width b of the slider is 60-70 mm, and the height c of the slider is 50-60 mm. The preferred size of the heat-resistant slider in this embodiment is: the slider The length a is 200mm, the slider width b is 70mm, and the slider height c is 50mm.

[0021] Such as figure 1 , figure 2 As shown, there is a half-groove 4 in the middle of the upper part of the heat-resistant slider, and the half-groove 4 runs through the heat-resistant slider transversely. A c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com